ZHANG Lei, WANG Yongfu, WANG Yongsheng, YUAN Wei

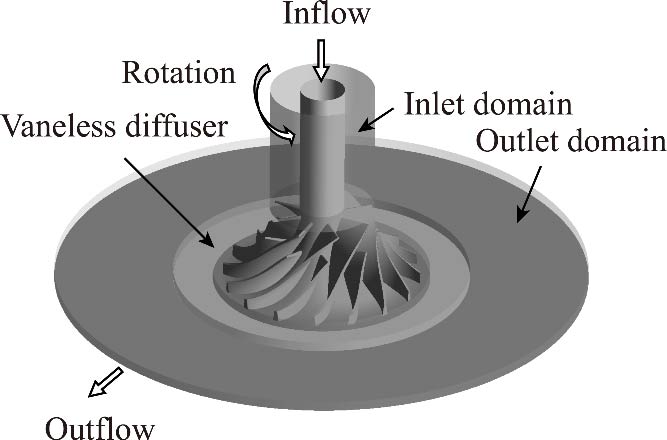

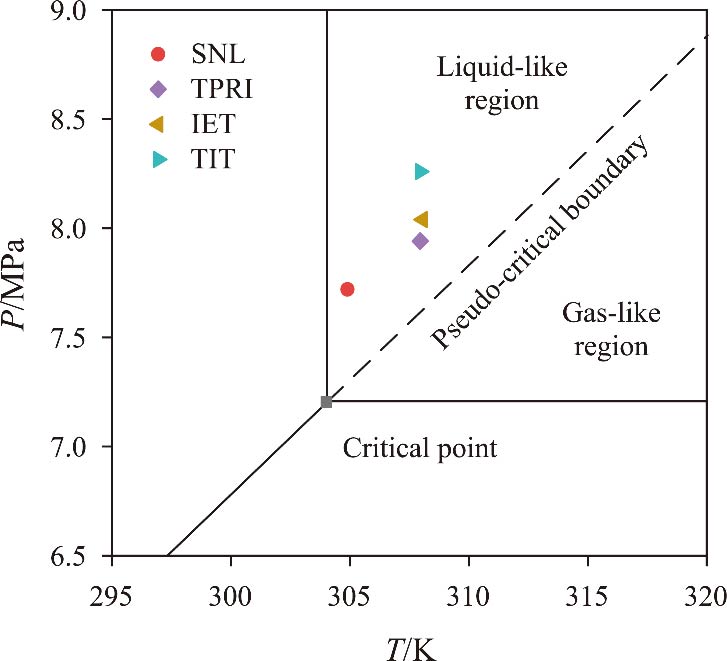

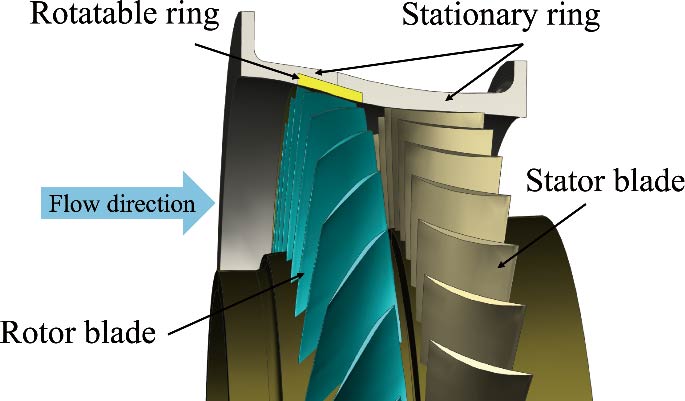

The high-density nature of supercritical carbon dioxide (S-CO2) allows for compact centrifugal compressor designs, where small absolute tip clearances result in relatively large normalized clearance ratios. This increases leakage flow at the impeller outlet, altering the velocity distribution, especially compared to air compressors. Steady-state simulations were conducted to investigate different relative tip clearances (CR=0%, 3.33%, 6.66%, and 10%). The results show that due to size effects, the types and distributions of secondary flows and vortices within the impeller vary significantly with tip clearance, affecting the jet-wake distribution at the impeller exit and the stall region in the diffuser. When the relative tip clearance exceeds a certain threshold, some secondary flow becomes trapped in the clearance, moving towards the impeller outlet and forming a low flow velocity region on the shroud side. Additionally, when the relative clearance is small, the wake region is primarily affected by channel and separation vortices. As the relative tip clearance increases, the secondary flow in the channel weakens, while the leakage flow intensifies, causing the leakage vortex to extend and dominate at higher blade heights, at the same time, the separation vortex to be formed near the suction side at mid to high positions. Consequently, the core region of the wake at the impeller outlet shifts from the hub side to the casing side, and the reverse flow region in the diffuser shifts from below 20% span (near the hub) to above 80% span (near the shroud).