[1] Ghaemi S., Rahimi P., Nobes D., Evaluation of StereoPIV measurement of droplet velocity in an effervescent spray. International Journal of Spray and Combustion Dynamics, 2010, 2(2): 103–123.

[2] Li J., Yan X., He K., Effect of non-axisymmetric endwall profiling on heat transfer and film cooling effectiveness of a transonic rotor blade. Journal of Turbomachinery, 2020, 142(5): 051006.

[3] Zhou W., Qenawy M., Shao H., et al., Turbine vane endwall film cooling with barchan-dune shaped ramp in a single-passage transonic wind tunnel. International Journal of Heat and Mass Transfer, 2020, 162: 120350.

[4] Zhou Z., Li H., Wang H., et al., Film cooling of cylindrical holes on turbine blade suction side near leading edge. International Journal of Heat and Mass Transfer, 2019, 141: 669–679.

[5] Lin J., Li H., You R., et al., Experimental study on the film cooling characteristics of three complex tip structures. Journal of Thermal Science, 2023, 32(4): 1378–1392.

[6] Zhang G., Xie G., Bengt S., Investigation of interacting mechanism between film cooling and internal cooling structures of turbine blade. Journal of Thermal Science, 2023, 32(1): 330–350.

[7] Cho H., Goldstein R., Heat (mass) transfer and film cooling effectiveness with injection through discrete holes: Part II-on the exposed surface. Journal of Turbomachinery, 1995, 117(3): 451–460.

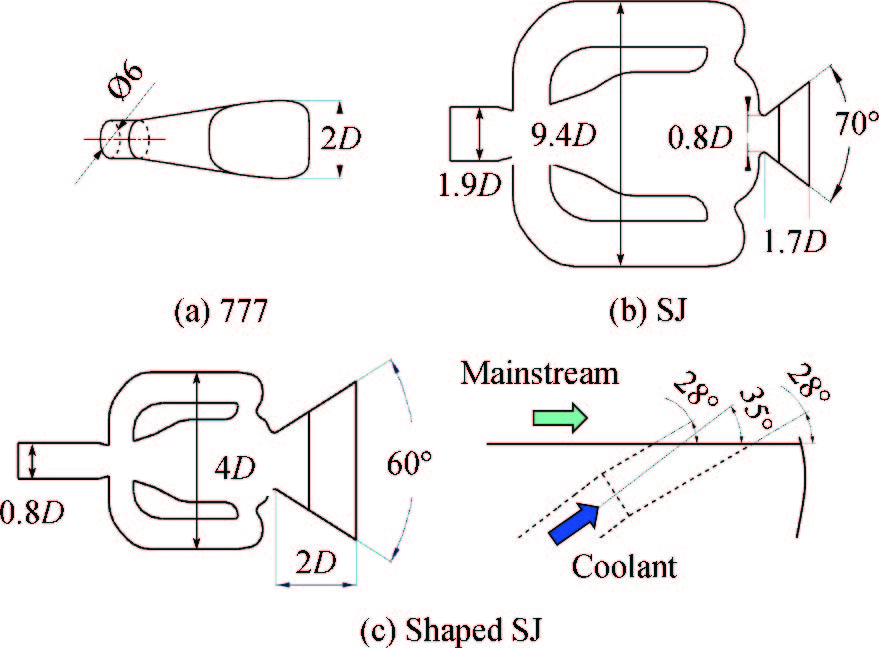

[8] Bunker R., A review of shaped hole turbine film-cooling technology. Journal of Heat Transfer, 2005, 127(4): 441.

[9] Cho H., Rhee D., Kim B., Enhancement of film cooling performance using a shaped film cooling hole with compound angle injection. JSME International Journal Series B Fluids and Thermal Engineering, 2001, 44(1): 99–110.

[10] Bogard D., Thole K., Gas turbine film cooling. Journal of Propulsion and Power, 2006, 22(2): 249–270.

[11] Wang X., Liu C., Fu Z., et al., Improvement of film cooling design for turbine vane leading edge considering combustor outflow. Journal of Thermal Science, 2024, 33(1): 311–327.

[12] Han J., Dutta S., Ekkad S., Gas turbine heat transfer and cooling technology. CRC Press, New York, 2012.

[13] Zhou W., Hu H., A novel sand-dune-inspired design for improved film cooling performance. International Journal of Heat and Mass Transfer, 2017, 110: 908–920.

[14] Wang K., Zhang X., Zhou W., et al., Correction method for film cooling effectiveness measurement with temperature gradient using endoscopic PSP and TSP Technique. Journal of Visulization, 2023, 26(5): 1101–1114.

[15] Li S., Zhang X., Zhou W., et al., Particle image velocimetry, delayed detached eddy simulation and data assimilation of inclined jet in crossflow. Journal of Visulization, 2024, 27(3): 307–322.

[16] Devani Y., Antošová Z., Trávníček Z., Annular impinging jets controlled by synthetic jets inducing a swirling flow character. Journal of Visulization, 2024, 27(3): 291–305.

[17] Abdelmegied B., Naguib A., Time-resolved visualization of an impinging jet subjected to bi-modal forcing. Journal of Visulization, 2024, 27(1): 1–18.

[18] Huang W., Zhang T., Zhou W., Influence of dust purge hole on thermal performance and particle deposition of a turbine blade with ribbed internal cooling channel. Journal of Visulization, 2023, 26(2): 299–316.

[19] Pu J., Zhou W., Wang, J., et al., Visualization and quantitation of unsteadiness of film cooling near stagnation line of a double-wall cooled vane leading edge. Journal of Visulization, 2023, 26(1): 113–129.

[20] Goldstein R., Film cooling. Advances in Heat Transfer, 1971, 7: 321–379.

[21] Schroeder R., Thole K., Adiabatic effectiveness measurements for a baseline shaped film cooling hole. ASME Turbo Expo 2014, Article No. GT2014-25992. https://doi.org/10.1115/GT2014-25992.

[22] Sundaram N., Thole, K., Bump and trench modifications to film-cooling holes at the vane-endwall junction. Journal of Turbomachinery, 2008, 130(4): 041013.

[23] Liu J., Malak M., Tapia L., et al., Enhanced film cooling effectiveness with new shaped holes. Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, 2010, 4: 1517–1527. https://doi.org/10.1115/GT2010-22774.

[24] Dhungel A., Lu Y., Phillips W., et al., Film cooling from a row of holes supplemented with antivortex holes. Journal of Turbomachinery, 2009, 131(2): 021007.

[25] Zhou W., Peng D., Wen X., et al., Unsteady analysis of adiabatic film cooling effectiveness behind circular, shaped, and sand-dune-inspired film cooling holes: Measurement using fast-response pressure-sensitive paint. International Journal of Heat and Mass Transfer, 2018, 125: 1003–1016.

[26] Hamed A., Tabakoff W., Wenglarz R., Erosion and deposition in turbomachinery. Journal of Propulsion and Power, 2006, 22(2): 350–360.

[27] Jain N., LeMoine A., Chaussonnet G., et al., A critical review of physical models in high temperature multiphase fluid dynamics: turbulent transport and particle-wall interactions. Applied Mechanics Reviews, 2021, 73(4): 040801.

[28] Kellersmann A., Weiler S., Bode C., et al., Surface roughness impact on low-pressure turbine performance due to operational deterioration. Journal of Engineering for Gas Turbines and Power, 2018, 140(6): 62601–62607.

[29] Sundaram N., Thole K., Effects of surface deposition, hole blockage, and thermal barrier coating spallation on vane endwall film cooling. Journal of Turbomachinery, 2007, 129(3): 599–607.

[30] Lawson S., Lynch S., Thole K., Simulations of multiphase particle deposition on a nonaxisymmetric contoured endwall with film-cooling. Journal of Turbomachinery, 2013, 135(3): 1–11.

[31] Wang J., Zhao Z., Tian L., et al., Effects of hole configuration on film cooling effectiveness and particle deposition on curved surfaces in gas turbines. Applied Thermal Engineering, 2021, 190: 116861.

[32] Wen X., Li Z., Zhou L., et al., Flow dynamics of a fluidic oscillator with internal geometry variations. Physics of Fluids, 2020, 32(7): 75111.

[33] Zhou W., Yuan L., Liu Y., et al., Heat transfer of a sweeping jet impinging at narrow spacings. Experimental Thermal and Fluid Science, 2019, 103: 89–98.

[34] Thurman D., Poinsatte P., Ameri A., et al., Investigation of spiral and sweeping holes. Journal of Turbomachinery, 2016, 138(9): 091007.

[35] Hossain M., Prenter R., Lundgreen R., et al., Experimental and numerical investigation of sweeping jet film cooling. Journal of Turbomachinery, 2018, 140(3): 031009.

[36] Zhou W., Wang K., Yuan T., et al., Spatiotemporal distributions of sweeping jet film cooling with a compact geometry. Physics of Fluids, 2022, 34(2): 025113.

[37] Kim S., Kim D., Kim K., Measurement of two-dimensional heat transfer and flow characteristics of an impinging sweeping jet. International Journal of Heat and Mass Transfer, 2019, 136: 415–426.

[38] Charbonnier D., Ott P., Jonsson M., Cottier F., et al., Experimental and numerical study of the thermal performance of a film cooled turbine platform. ASME Turbo Expo 2009: Power for Land, Sea, and Air, 2009, 3: 1027–1038.

[39] Johnson B., Hu H., Measurement uncertainty analysis in determining adiabatic film cooling effectiveness by using pressure sensitive paint technique. Journal of Turbomachinery, 2016, 138(12): 121004.

[40] Zhou W., Shao H., Qenawy M., et al., Improved turbine vane endwall film cooling by using sand-dune-inspired design. Journal of Thermal Science, 2022, 31(3): 958–973.

[41] Lawson S., Thole K., Effects of simulated particle deposition on film cooling. Journal of Turbomachinery, 2011, 133(2): 1–9.

[42] Zhang T., Dong Z., Huang W., et al., In situ multi-perspective scanning of 3D particle deposition on flat plates with film cooling and determination of practical model parameters. Experimental Thermal and Fluid Science, 2024, 151: 111109.

[43] Wen X., Liu J., Li Z., et al., Flow dynamics of sweeping jet impingement upon a large convex cylinder. Experimental Thermal and Fluid Science, 2019, 107(1): 1–15.

[44] Zhang T., Huang W., Zhou W., et al., Unveiling particle deposition characteristics on flat plate with a shaped film cooling hole. International Journal of Heat and Mass Transfer, 2023, 216: 124584.