[1] Zheng X.Q., Li Z.H., Blade-end treatment to improve the performance of axial compressors: An overview. Progress in Aerospace Sciences, 2017, 88(1): 1–14.

[2] Si C.X., Wu Z.H., Simplified numerical models of the unsteady tip leakage flow in compressor. Journal of Thermal Science, 2023, 32(6): 2386–2399.

[3] Vo H.D., Cameron J.D., Morris S.C., Control of short length-scale rotating stall inception on a high-speed axial compressor with plasma actuation. ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 2008, 6: 533–542.

[4] Benini E., Biollo R., Ponza R., Efficiency enhancement in transonic compressor rotor blades using synthetic jets: a numerical investigation. Applied Energy, 2011, 88(3): 953–962.

[5] Fietzke B., Mihalyovics J., King R., et al., Binary repetitive model predictive active flow control applied to an annular compressor stator cascade with periodic disturbances. Journal of Engineering for Gas Turbines and Power, 2022, 144 (1): 011029.

[6] Spence S.W.T., O'Neill J.W., Cunningham G., An investigation of the flow field through a variable geometry turbine stator with vane endwall clearance. Proceedings of the Institution of Mechanical Engineers Part A: Journal of Power and Energy, 2006, 220(12): 899–910.

[7] Zhong J.J., Wu W.Y., Han S.B., Research progress of tip winglet technology in compressor. Journal of Thermal Science, 2021, 30(1): 18–31.

[8] Zhao A., Wu W.Y., Hu Y., et al., Influence of the chordwise distribution of tip winglets on the stability of a high-load compressor stage. Physics of Fluids, 2023, 35(10): 104111.

[9] Wang N.F., Liu C., Jiang D.X., Prediction of transient vibration response of dual-rotor-blade-casing system with blade off. Proceedings of the Institution of Mechanical Engineers Part G: Journal of Aerospace Engineering, 2019, 233(11): 5164–5176.

[10] Wu G.H., Zheng L.J., Wu K.Q., Numerical analysis and PIV measurements of tip vortex in an axial rotor with skewed-swept blade at its leading edge. Journal of Thermal Science, 2004, 13(1): 16–23.

[11] Koch C.C., Experimental evaluation of outer case blowing or bleeding of single stage axial-flow compressor. NASA CR-54592, 1970.

[12] Oscarson R.P., Wright D.L., Experimental evaluation of a honeycomb rotor shroud configuration to improve the stall margin of a 0.5 hub-hip ratio single stage compressor, NASA CR-72809, 1970.

[13] Osborn W.M., Lewis G.W., Heidelberg L.J., Effect of porous casing treatment on stall limit and on overall performance of an axial-flow compressor rotor, NASA TND-6537, 1970.

[14] Houghton T., Day I., Enhancing the stability of the subsonic compressors using casing grooves. Journal of Turbomachinery-Transactions of the ASME, 2012, 113(4): 021007.

[15] Zhu J., Chu W., Lu X., Design and experimental investigations of a new type of casing treatment for an axial flow compressor. Proceedings of the Institution of Mechanical Engineers Part A: Journal of Power and Energy, 2006, 220(5): 207–215.

[16] Wilke I., Kau H.P., A numerical investigation of the flow mechanisms in a HPC front stage with axial slots. ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, Georgia, USA, 2003, 6: 465‒477.

[17] Hah C., The inner workings of axial casing grooves in a one and a half stage axial compressor with a large rotor tip gap: Changes in stall margin and efficiency. Journal of Turbomachinery, 2019, 141(1): 011001.

[18] Zhang H.G., Liu W.H., Wang E.H., et al., Mechanism investigation of enhancing the stability of an axial flow rotor by blade angle slots. Proceedings of the Institution of Mechanical Engineers Part G: Journal of Aerospace Engineering, 2019, 233(10): 4750–4764.

[19] Kumar S.S., Alone D.B., Timmaiah S.M., et al., Aerodynamic behavior of a transonic axial flow compressor stage with self-recirculating casing treatment. Aerospace Science and Technology, 2021, 112(5): 106587.

[20] Vuong T.D., Kim K.Y., Dinh C.T., Recirculation-groove coupled casing treatment for a transonic axial compressor, Aerospace Science and Technology, 2021, 111(3): 106556.

[21] Sun D.K., Nie C.Q., Liu X.H., et al., Further investigation on transonic compressor stall margin enhancement with stall precursor-suppressed casing treatment. Journal of Turbomachinery-Transactions of the ASME, 2016, 138(2): 021001.

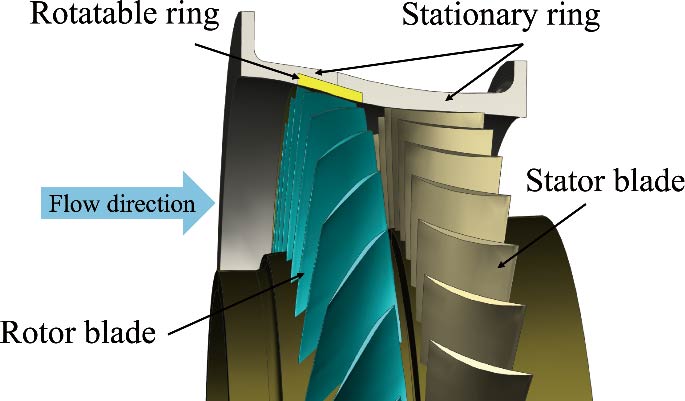

[22] Zhong J.J., Wu W.Y., A rotatable inner endwall casing for compressor rotor, China, Patent ZL201910069085.1, 2023.12.

[23] Hu Y., Wu W.Y., Zhao A., et al., Influence of the rotation characteristics of the controllable speed casing on the flow stability of a high-load compressor stage. Aerospace Science and Technology, 2023, 141(10): 108575.

[24] Wu W.Y., Zhao J.Y., Zhong J.J., Influence of the rotating direction and speed of controllable speed casing on the flow stability of a transonic compressor rotor under design condition. Aerospace Science and Technology, 2023, 126(7): 107630.

[25] Zhong J.J., Hu Y., Zhao A., et al., Influence of the terminal position of the rotatable ring of controllable speed casing on the flow stability of a high-load compressor stage. ASME Turbo Expo 2024: Turbomachinery Technical Conference and Exposition, London, United Kingdom, 2024.

DOI: 10.1115/GT2024-123009.

[26] Kan X.X., Suo L.C., Lei H.D., et al., Shock wave spectrum forming around the compound five-hole probe and its influence on pneumatic parameters acquisition during subsonic to supersonic flow. Journal of Thermal Science, 2024, 33(6): 2019–2031.

[27] Hunt J.C.R., Wray A.A., Moin P., Eddies, stream, and convergence zones in turbulent flows, Center for Turbulence Research Report CTR-S88, 1988.

[28] Zhao A., Wu W.Y., Hu Y., et al., Influence of the chordwise distribution of tip winglets on the stability of a high-load compressor stage. Physics of Fluids, 2023, 35(10): 104111.