[1] National Bureau of Statistics of China, China Statistical Yearbook. China Statistics Press, Beijing, 2023.

[2] Liu Y., Tan W., Liang S., et al., Effect of limestone on NO emission during the co-combustion of semi-coke and bituminous coal. Journal of Thermal Science, 2024, 33(6): 2413–2425.

[3] Xu S., Zeng X., Han Z., et al., Quick pyrolysis of a massive coal sample via rapid infrared heating. Applied Energy, 2019, 242: 732–740.

[4] Wang L., Ye T., Ma X., et al., Kinetics and products distribution study on the catalytic effect of Zn/HZSM-5 over pyrolysis of chlorella through TG-FTIR and Py-GC/MS. Journal of Thermal Science, 2023, 32(4): 1635–1643.

[5] Gong Z., Zhang H., Liu C., et al., Co-pyrolysis characteristics and kinetic analysis of oil sludge with different additives. Journal of Thermal Science, 2021, 30(4): 1452–1467.

[6] Zhang Y., Liu S., Fan L., et al., Oil production from microwave-assisted pyrolysis of a low rank American brown coal. Energy Conversion and Management, 2018, 159: 76–84.

[7] Jin X., Li X., Kong J., et al., Insights into coke formation during thermal reaction of six different distillates from the same coal tar. Fuel Processing Technology, 2021, 211: 106592.

[8] Miura K., Mild conversion of coal for producing valuable chemicals. Fuel Processing Technology, 2000, 62(2–3): 119–135.

[9] Zhang Y., Gao N., Quan C., et al., Research progress on high temperature oil-gas dust removal technology during pyrolysis of low-rank coal. Chemical Industry and Engineering Progress, 2022, 41(4): 1814–1824.

[10] Shang J., Niu B., Niu M., et al., Coal grading utilization technologies based on coal pyrolysis: Review and prospect. Clean Coal Technology, 2023, 29(07): 1–20.

[11] Jin L., Bai X., Li Y., et al., In-situ catalytic upgrading of coal pyrolysis tar on carbon-based catalyst in a fixed-bed reactor. Fuel Processing Technology, 2016, 147: 41–46.

[12] Zhou Q., Liu Q., Shi L., et al., Behaviors of coking and radicals during reaction of volatiles generated from fixed-bed pyrolysis of a lignite and a subbituminous coal. Fuel Processing Technology, 2017, 161: 304–310.

[13] Hosokai S., Kumabe K., Ohshita M., et al., Mechanism of decomposition of aromatics over charcoal and necessary condition for maintaining its activity. Fuel, 2008, 87(13): 2914–2922.

[14] Xue F., Li D., Guo Y., et al., Technical progress and the prospect of low-rank coal pyrolysis in China. Energy Technology, 2017, 5(11): 1897–1907.

[15] Qu X., Liang P., Wang Z., et al., Pilot development of a polygeneration process of circulating fluidized bed combustion combined with coal pyrolysis. Chemical Engineering & Technology, 2011, 34(1): 61–68.

[16] Silvestre W.P., Pauletti G.F., Godinho M., et al., Fodder radish seed cake pyrolysis for bio-oil production in a rotary kiln reactor. Chemical Engineering and Processing - Process Intensification, 2018, 124: 235–244.

[17] Daugaard T.J., Dalluge D.L., Brown R.C., et al., Effect of thermophysical properties of heat carriers on performance of a laboratory-scale auger pyrolyzer. Fuel Processing Technology, 2018, 176: 182–189.

[18] Qu X., Zhang R., Sun D., et al., Experiment study on pyrolysis of Huolinhe lignite with solid heat carrier. Journal of Fuel Chemistry and Technology, 2011, 35(2): 85–89.

[19] Zhang Y., Liang P., Zhu J., et al., Secondary catalytic reaction of circulating ash on the primary volatiles of coal pyrolysis. Journal of Energy Engineering, 2017, 143(5): 04017021.

[20] Chen Z., Li Y., Lai D., et al., Coupling coal pyrolysis with char gasification in a multi-stage fluidized bed to co-produce high-quality tar and syngas. Applied Energy, 2018, 215: 348–355.

[21] Li T., Du T., Shen Y., et al., Effect of char powder on gaseous tar reaction during low-rank coal pyrolysis. Journal of Fuel Chemistry and Technology, 2021, 49(5): 626–633.

[22] Lyu Q., Yu K., Zhu Z., et al., Pilot plant research on fast pyrolysis of coal in circulating fluidized bed with hot char carrier. Journal of China Coal Society, 2012, 37(9): 1591–1595.

[23] Fan X., Lu Q., Na Y., et al., Experimental study on coal multi-generation in dual fluidized beds. Journal of Thermal Science, 2007, 16(3): 277–282.

[24] Zhang X., Zhu S., Song W., et al., Experimental study on conversion characteristics of anthracite and bituminous coal during preheating-gasification. Fuel, 2022, 324: 124712.

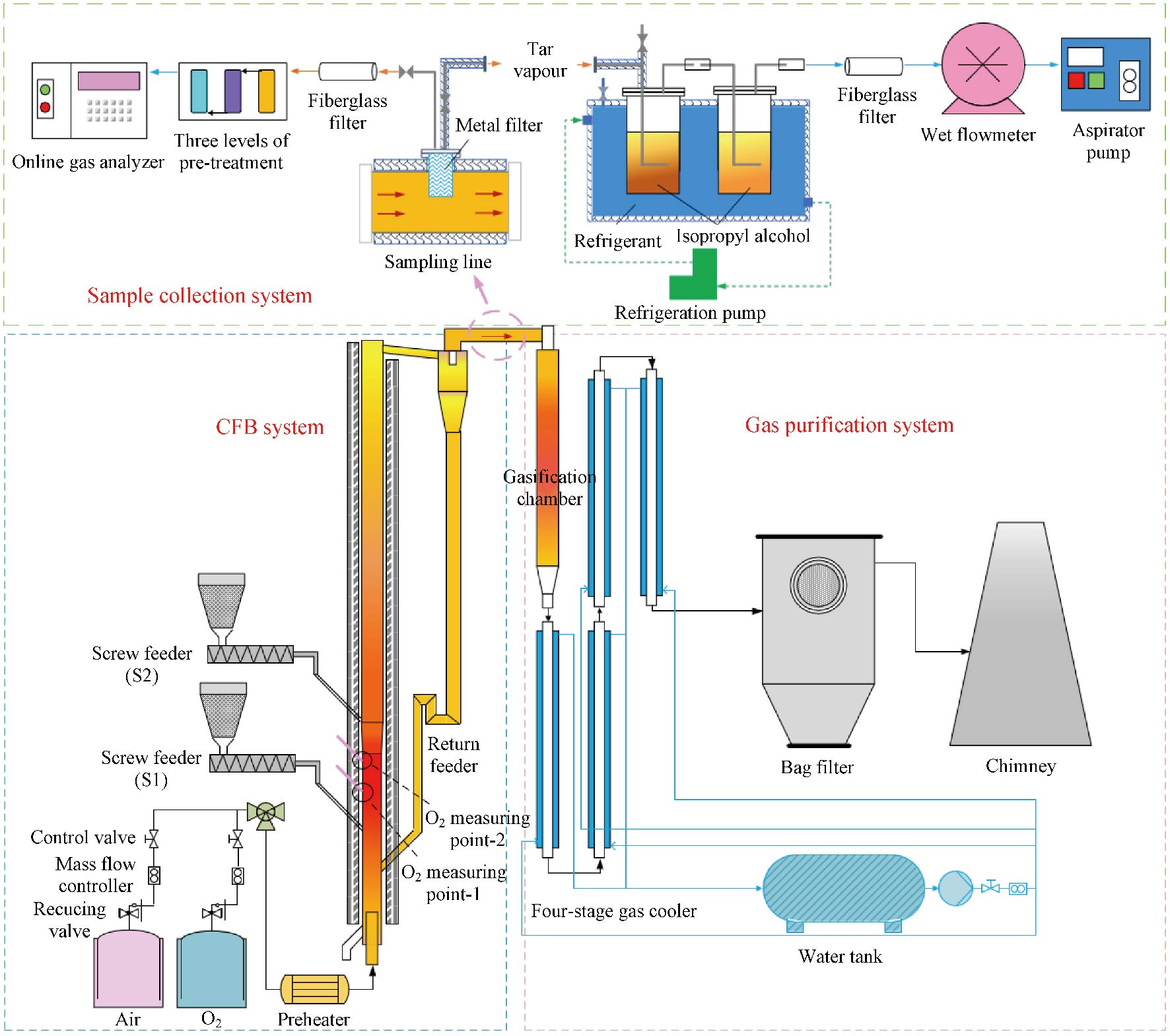

[25] Zhang X., Qi X., Gao S., et al., An experimental investigation on gasification-pyrolysis coupling characteristics of pulverized coal in circulating fluidized bed. Journal of the Energy Institute, 2024, 116: 101751.

[26] Song X., Wang Q., Zhu Y., et al., Experimental study on coal partial gasification coproducing char, tar, and gas. Journal of Thermal Science, 2023, 32(6): 2297–2309.

[27] Liu C., Huang Y., Niu M., et al., Influences of equivalence ratio, oxygen concentration and fluidization velocity on the characteristics of oxygen-enriched gasification products from biomass in a pilot-scale fluidized bed. International Journal of Hydrogen Energy, 2018, 43(31): 14214–14225.

[28] Liu F., Wang L., Yang W., et al., Study on deep-processing technology of medium and low temperature coal tar and analysis of its market prospect. Modern Chemical Industry, 2012, 32(7): 7–11.

[29] Qi X., Gao S., Zhu Z., et al., Reverse combustion propagation in an oxygen-limited and-enriched N2/O2 flow for a bed packed with rice husk. Combustion and Flame, 2024, 260: 113205.

[30] Liu L., Kumar S., Wang Z., et al., Catalytic effect of metal chlorides on coal pyrolysis and gasification part I. Combined TG-FTIR study for coal pyrolysis. Thermochimica Acta, 2017, 655: 331–336.

[31] Zhong M., Zhang Z., Zhou Q., et al., Continuous high-temperature fluidized bed pyrolysis of coal in complex atmospheres: Product distribution and pyrolysis gas. Journal of Analytical and Applied Pyrolysis, 2012, 97: 123–129.

[32] Gao R., Dou B., Chang Q., et al., Effect of temperature and hydrogen on product distribution and evolution of char structure during pyrolysis of bituminous coal in a drop tube furnace. Fuel, 2020, 267: 117078.

[33] Sharma R.K., Wooten J.B., Baliga V.L., et al., Characterization of chars from pyrolysis of lignin. Fuel, 2004, 83(11–12): 1469–1482.

[34] Jones J., Pourkashanian M., Rena C., et al., Modelling the relationship of coal structure to char porosity. Fuel, 1999, 78(14): 1737–1744.

[35] Arenillas A., Rubiera F., Pis J.J., Simultaneous thermogravimetric-mass spectrometric study on the pyrolysis behaviour of different rank coals. Journal of Analytical and Applied Pyrolysis, 1999, 50(1): 31–46.

[36] Petersen H.I., Rosenberg P., Nytoft H.P., Oxygen groups in coals and alginite-rich kerogen revisited. International Journal of Coal Geology, 2008, 74(2): 93–113.

[37] Ye C., Wang Q., Yu L., et al., Characteristics of coal partial gasification experiments on a circulating fluidized bed reactor under CO2-O2 atmosphere. Applied Thermal Engineering, 2018, 130: 814–821.

[38] Shamsi A., Catalytic and thermal cracking of coal-derived liquid in a fixed-bed reactor. Industrial & Engineering Chemistry Research, 1996, 35(4): 1251–1256.