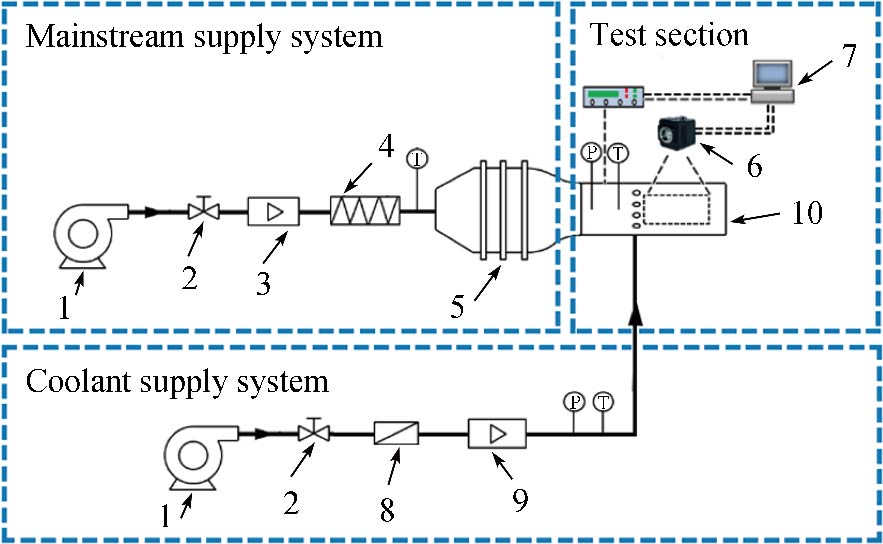

Film cooling remains a critical technique for protecting turbine blades under high thermal loads, yet developing high-performance film cooling structures while maintaining structural integrity and manufacturability remains a major challenge. Serrated trenched-hole designs offer enhanced coolant coverage and manufacturability advantages over conventional shaped holes, but their performance under various streamwise pressure gradient conditions has not been systematically explored. This study investigates the impacts of mainstream streamwise pressure gradients, including zero, adverse, and favorable, on characteristics of serrated trenched-hole film cooling, with comparisons to conventional cylindrical holes. A combination of experimental measurements and Large Eddy Simulation (LES) is employed to investigate flow dynamics and film cooling performance under various pressure gradients and at blowing ratios of M=0.5 and M=1.5. Experimental results demonstrate that the serrated trench consistently enhances film cooling effectiveness. Under adverse pressure gradients, it mitigates the reduction in film cooling performance and improves both streamwise and spanwise coverage. Particularly at M=1.5, the serrated trench improves near-exit region film cooling effectiveness by roughly 2–3 times compared to cylindrical holes. Under favorable pressure gradient, the serrated trench further optimizes cooling effectiveness by promoting both spanwise continuity and streamwise expansion of the coolant film, with the maximum film cooling effectiveness in the near-exit region reaching approximately 0.9. Favorable streamwise pressure gradients enhance the laterally averaged film cooling effectiveness of the serrated trench by 10%–18% compared to the zero-pressure gradient case, especially at M=1.5. While adverse pressure gradients lead to a modest reduction of film cooling effectiveness, with decreases of up to 10% in the near-exit region at M=0.5 and 10%–15% in the far-field at M=1.5. LES results at M=1.5 reveal that film cooling enhancement under favorable pressure gradients is closely associated with the formation of Anti-CVP (Anti-Counter-rotating Vortex Pair) and inter-hole vortices, which facilitate lateral coolant transport and improve spanwise coverage. Conversely, adverse pressure gradients induce jet lift-off, intensifying mainstream-coolant mixing, leading to diminished cooling effectiveness. Turbulence kinetic energy (TKE) analysis further supports these findings. The novelty of this work lies in its quantitative assessment of streamwise pressure gradient effects on trenched-hole film cooling, which is scarcely addressed in prior research, and in its integrated use of experimental and LES approaches to elucidate both performance trends and underlying flow mechanisms.

HUANG Kenan, ZHANG Jingzhou, LI Guoneng, ZHU Yiyuan, SHEN Rong, BU Zhongming

. Mainstream Pressure Gradient on Film Cooling Characteristics of a Serrated Trenched-Hole[J]. Journal of Thermal Science, 2026

, 35(1)

: 97

-114

.

DOI: 10.1007/s11630-025-2208-0