[1] Beyne E., The rise of the 3rd dimension for system intergration. 2006 International Interconnect Technology Conference, 2006. DOI: 10.1109/IITC.2006.1648629.

[2] Lee J., Darges S.J., Mudawar I., Experimental investigation and analysis of parametric trends of instability in two-phase micro-channel heat sinks. International Journal of Heat and Mass Transfer, 2021, 170: 120980.

[3] Ge J.L., Xia F.F., Zhang C.B., Huang Y.P., Performance enhancement of single-phase immersion liquid-cooled data center servers. Journal of Thermal Science, 2024, 33(5): 1757–1772.

[4] Shang X.S., Wang Y.X., Li Q.W., et al., Modeling of rectangular microchannel heat sink with non-uniform channels and multi-objective optimization. Journal of Thermal Science, 2024, 33(5): 1701–1711.

[5] Venkatadri V., Sammakia B., Srihari K., et al., A review of recent advances in thermal management in three dimensional chip stacks in electronic systems. Journal of Electronic Packaging, 2011, 133(4): 041011.

[6] Zając P., Compact thermal modelling tool for fast design space exploration of 3D ICs with integrated microchannels. Energies, 2020, 13(9): 2217.

[7] Wu T., Wang L.Z., Tang Y.C., et al., Flow and heat transfer performances of liquid metal based microchannel heat sinks under high temperature conditions. Micromachines, 2022, 13(1): 95.

[8] Khoshmanesh K., Tang S.Y., Zhu J.Y., et al., Liquid metal enabled microfluidics. Lab on a Chip, 2017, 17(6): 974–993.

[9] Elassy K.S., Rahman M.A., Shiroma W.A., et al., Liquid-metal nodal sheet for reconfigurable devices and circuits. IEEE Access, 2020, 8: 167596–167603.

[10] Li S.M., Li J.S., Hao Q.T., et al., Research on the dual-frequency electromagnetic shaping of liquid metal. Journal of Materials Processing Technology, 2003, 137(1): 204–207.

[11] Li M.T., Su Y.J., Zhang H., et al., Light-powered direction-controlled micropump. Nano Research, 2018, 11(4): 1810–1821.

[12] Lian T.T., Wang Z.Z., Yuan H., et al., Heat dissipation characteristics of a jetting staggered microchannel for cooling a large-area high-performance SOC chip. 2022 21st IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm), 2022.

DOI: 10.1109/iTherm54085.2022.9899524.

[13] Hu L., Wang L., Ding Y.J., et al., Manipulation of liquid metals on a graphite surface. Advanced Materials, 2016, 28(41): 9210–9217.

[14] Deng Y.G., Zhang M.M., Jiang Y., et al., Two-stage multichannel liquid-metal cooling system for thermal management of high-heat-flux-density chip array. Energy Conversion and Management, 2022, 259: 115591.

[15] Ren Y., Wang X.L., Liu J., Fabrication of high-resolution flexible circuits and sensors based on liquid metal inks by spraying and wiping processing. IEEE Transactions on Biomedical Circuits and Systems, 2019, 13(6): 1545–1551.

[16] Rajamani K., Toprak M.S., Zhang F., et al., Unlocking the potential of magnetic refrigeration: Investigating the compatibility of the Ga-based liquid metal with a La(Fe,Mn,Si)13hz magnetocaloric material for enhanced long-term stability. ACS Omega, 2023, 8(51): 49027–49036.

[17] Zhang Z., Wu Z., Luo X., et al., Numerical study on convective heat transfer of liquid metal gallium in turbine guide vane. Aerospace, 2023, 10(6): 548.

[18] Sarafraz M.M., Hart J., Shrestha E., et al., Experimental thermal energy assessment of a liquid metal eutectic in a microchannel heat exchanger equipped with a (10 Hz/50 Hz) resonator. Applied Thermal Engineering, 2019, 148: 578–590.

[19] Bai P., Li S., Tao D., et al., Tribological properties of liquid-metal galinstan as novel additive in lithium grease. Tribology International, 2018, 128: 181–189.

[20] Deng Z.S., Liu J., Numerical evaluation on the heat dissipation capability of liquid metal based chip cooling device. Electronic and Photonic Packaging, Electrical Systems Design and Photonics, and Nanotechnology, 2005. DOI: 10.1115/imece2005-80189.

[21] Shi C., Zou Z., Lei Z., et al., Heterogeneous integration of rigid, soft, and liquid materials for self-healable, recyclable, and reconfigurable wearable electronics. Science Advances, 2020, 6(45): 123547.

[22] Zhang D., Feng H., Hu H., et al., Research status of embrittlement mechanism of liquid metal. Materials Reports, 2023, 37(z2): 320–328.

[23] Hojna A., Di Gabriele F., Klecka J., Characteristics and liquid metal embrittlement of the steel T91 in contact with lead-bismuth eutectic. Journal of Nuclear Materials, 2016, 472: 163–170.

[24] Luo W.J., Vishwakarma P., Panigrahi B., Hydrodynamic influence on thermal management of flexible heatsink devices embedded with out-of-plane intricate microchannel design. International Communications in Heat and Mass Transfer, 2023, 144: 106792.

[25] Wang X., Li K., Wang Y., et al., Progress of polymer/gallium-based liquid metal composites. Gaofenzi Cailiao Kexue Yu Gongcheng/Polymeric Materials Science and Engineering, 2021, 37(1): 327–334.

[26] Huang Y.K., Pan R.J., Rehnlund D., Wang Z.H., Nyholm L., First-cycle oxidative generation of lithium nucleation sites stabilizes lithium-metal electrodes. Adv Energy Mater, 2021, 11(9): 13.

[27] Dynamicity of atoms in a liquid metal catalyst enables selective propylene synthesis. Nature Nanotechnology, 2024, 19: 275–276.

[28] Ki S., Shim J., Oh S., et al., Gallium-based liquid metal alloy incorporating oxide-free copper nanoparticle clusters for high-performance thermal interface materials. International Journal of Heat and Mass Transfer, 2021, 170: 121012.

[29] Lin Z., Liu H., Li Q., et al., High thermal conductivity liquid metal pad for heat dissipation in electronic devices. Applied Physics A, 2018, 124(5): 368.

[30] Lü X., Tang H., Wang H., et al., Ultra-soft thermal self-healing liquid-metal-foamed composite with high thermal conductivity. Composites Science and Technology, 2022, 226: 109523.

[31] Zhao L., Chu S., Chen X., et al., Efficient heat conducting liquid metal/CNT pads with thermal interface materials. Bulletin of Materials Science, 2019, 42(4): 192.

[32] Tan L., Zhang J., Shen J., Liquid metal/metal porous skeleton with high thermal conductivity and stable thermal reliability. Journal of Materials Science, 2023, 58(47): 17829–17842.

[33] Xing W., Chen S., Wang H., et al., Construction of 3D conductive network in liquid gallium with enhanced thermal and electrical performance. Advanced Materials Technologies, 2021, 7(5): 2100970.

[34] Kuang H., Wu B., Wang J., et al., Wettability and thermal contact resistance of thermal interface material composited by gallium-based liquid metal on copper foam. International Journal of Heat and Mass Transfer, 2022, 199: 123444.

[35] Jiao T., Deng Q., Jing G., et al., Enhanced thermal conductivity of liquid metal composite with lower surface tension as thermal interface materials. Journal of Materials Research and Technology, 2023, 24: 3657–3669.

[36] Wang B., Wang L., Yang F., et al., Air-cooling system optimization for IGBT modules in mmc using embedded o-shaped heat pipes. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2021, 9(4): 3992–4003.

[37] van Erp R., Soleimanzadeh R., Nela L., et al., Co-designing electronics with microfluidics for more sustainable cooling. Nature, 2020, 585(7824): 211–216.

[38] Li C., Li J., A dumbbell-shaped 3D flat plate pulsating heat pipe module augmented by capillarity gradient for high-power server cpu onsite cooling. Energy Conversion and Management, 2023, 292: 117384.

[39] He W., Zhang J., Guo R., et al., Performance analysis and structural optimization of a finned liquid-cooling radiator for chip heat dissipation. Applied Energy, 2022, 327: 120048.

[40] Zhang P., Han R., Wang D., et al., Design of heat sink in power electronic device using liquid metal. IOP Conference Series: Earth and Environmental Science, 2020, 453(1): 012061.

[41] Zhang Y., Wang J., Liu W., et al., Heat transfer and pressure drop characteristics of R134a flow boiling in the parallel/tandem microchannel heat sinks. Energy Conversion and Management, 2017, 148: 1082–1095.

[42] Cheng J., Wang Z., Sun J., et al., Numerical simulation of condensation heat transfer characteristics of R134a at high vapor velocity under different angles. International Journal of Heat and Mass Transfer, 2023, 213: 124332.

[43] Pramanick S., Dey P., Saha S.K., Development of numerical model to study the effect of condensate liquid layer on condensation heat transfer of R134a in minichannel. Heat and Mass Transfer, 2022, 58(11): 2029–2046.

[44] Wang J., Wang J., Li J.M., R134a condensation flow regime and pressure drop in horizontal microchannals cooled symmetrically and asymmetrically. International Journal of Heat and Mass Transfer, 2017, 115: 1091–1102.

[45] Yıldız A., Yıldırım R., Investigation of using R134a, R1234yf and R513A as refrigerant in a heat pump. International Journal of Environmental Science and Technology, 2020, 18(5): 1201–1210.

[46] Waqas H., Khan S.A., Farooq U., et al., Thermal transport analysis of six circular microchannel heat sink using nanofluid. Sci Rep, 2022, 12(1): 8035.

[47] Ho C.J., Peng J.K., Yang T.F., et al., Comparison of cooling performance of nanofluid flows in mini/micro-channel stacked double-layer heat sink and single-layer micro-channel heat sink. International Journal of Thermal Sciences, 2023, 191: 108375.

[48] Li C., Huang J., Shang Y., et al., Study on the flow and heat dissipation of water-based alumina nanofluids in microchannels. Case Studies in Thermal Engineering, 2020, 22: 100746.

[49] Fang J., Xu X., Zhang Y., et al., Enhanced heat dissipation for macroscopic metals achieved by a single- layer graphene. Advanced Materials Interfaces, 2024, 11: 2300877.

[50] Liu C., Xu H., Yang J., et al., Temperature adjustable thermal conductivity and thermal contact resistance for liquid metal/paraffin/olefin block copolymer interface material. International Journal of Thermal Sciences, 2022, 179: 107679.

[51] Scarpa F., Slimani S., Galinstan liquid metal as the heat transfer fluid in magnetic refrigeration. Applied Thermal Engineering, 2023, 232: 120971.

[52] Lian T., Xia Y., Wang Z., et al., Thermal property evaluation of a 2.5D integration method with device level microchannel direct cooling for a high-power gan hemt device. Microsystems & Nanoengineering, 2022, 8(1): 119.

[53] Alihosseini Y., Azaddel M., Moslemi S., et al., Effect of liquid cooling on PCR performance with the parametric study of cross-section shapes of microchannels. Scientific Reports, 2021, 11(1): 16072.

[54] Xu Y., Cao W., Zhu J., Analysis on heat transfer and flow performance of tapered microchannels. Mechanical Engineer, 2023, (10): 27–30.

[55] Chen H., Chen C., Zhou Y., et al., Evaluation and optimization of a cross-rib micro-channel heat sink. Micromachines, 2022, 13(1): 132.

[56] Ma S., Jiang H., Cheng T., Structural design and performance optimization of manifold microchannel heat exchangers. Kung Cheng Je Wu Li Hsueh Pao/Journal of Engineering Thermophysics, 2023, 44(5): 1296–1303.

[57] Luo W.J., Vishwakarma P., Panigrahi B., Synergistic thermal and hydrodynamic effects in 3D-printed heat sinks with intricate microchannel patterns. Microfluidics and Nanofluidics, 2024, 28(9): 60.

[58] Guo Y., Zhu C.Y., Gong L., et al., Numerical simulation of flow boiling heat transfer in microchannel with surface roughness. International Journal of Heat and Mass Transfer, 2023, 204: 123830.

[59] Acosta-Cuevas J.M., García-Ramírez M.A., Hinojosa-Ventura G., et al., Surface roughness analysis of microchannels featuring microfluidic devices fabricated by three different materials and methods. Coatings, 2023, 13(10): 1676.

[60] Xiang X., Study on cooling capacity of micro-/mini-channel and micro-jet impingement heat sinks using liquid metals. Huazhong University of Science and Technology, Hubei, China, 2021.

[61] Zhang X.D., Li X.Z., Zhou Y.X., et al., Vascularized liquid metal cooling for thermal management of kW high power laser diode array. Applied Thermal Engineering, 2019, 162: 114212.

[62] Wang M., Preparation and thermal conductivity of liquid metal-based and silicone-based thermal interface materials. Qingdao University of Science and Technology, Shandong, China, 2018.

[63] Zhang L., Wang Z., Molecular dynamics simulation of thermal transport process of liquid metal. Journal of University of Chinese Academy of Sciences, 2015, 32(01): 25–30.

[64] Wei S., High-performance thermal interface materials with diphase continuous structure reinforced by liquid metal. University of Science and Technology of China, Anhui, China, 2020.

[65] Gao Y.X., Liu J., Wang X.P., et al., Investigation on the performance of gallium based liquid metal thermal interface materials. Kung Cheng Je Wu Li Hsueh Pao/Journal of Engineering Thermophysics, 2017, 38(5): 1077–1081.

[66] Hua Q., Yu G., Hong W., et al., Stretchable thermal interface material with both thermal conduction and self-healing functions based on liquid metal/polysulfide rubber. Gaofenzi Cailiao Kexue Yu Gongcheng/Polymeric Materials Science and Engineering, 2021, 37(7): 153–161.

[67] Sun F., Duan X., Cui H., et al., Numerical analysis for heat transfer of liquid metals in delivery tube. Chinese Journal of Engineering, 1997, 19(01): 68–74.

[68] Cui W., Jiang Z., Hao T., et al., Heat transfer performance of oscillating heat pipe with micro-nano droplets of liquid metal. Chemical Industry and Engineering Progress, 2022, 41(01): 95–103.

[69] Gañán-Calvo A.M., Guo W., Xi H.D., et al., Pressure-driven filling of liquid metal in closed-end microchannels. Physical Review E, 2018, 98(3): 032602.

[70] Li P., Gao Y., Yang Y., et al., Numerical simulation of self-driven heat transfer based on thermosyphon effect of room temperature liquid metal. Journal of Engineering Thermophysics, 2014, 35(01): 179–182.

[71] Cui Y.T., Ding Y.J., Xu S., et al., Liquid metal corrosion effects on conventional metallic alloys exposed to eutectic gallium-indium alloy under various temperature states. International Journal of Thermophysics, 2018, 39(10): 1–14.

[72] Yang F., Ding J., Liu H., et al., Study on anti-corrosion technology and corrosion mechanism of liquid gain alloy to copper. Cailiao Daobao/Materials Reports, 2021, 35(20): 20076–20080 and 20112.

[73] Böhne C., Meschut G., Biegler M., et al., Avoidance of liquid metal embrittlement during resistance spot welding by heat input dependent hold time adaption. Science and Technology of Welding and Joining, 2020, 25(7): 617–624.

[74] Handschuh-Wang S., Wang T., Zhu L., et al., Corrosion-resistant functional diamond coatings for reliable interfacing of liquid metals with solid metals. ACS Applied Materials & Interfaces, 2020, 12(36): 40891–40900.

[75] Cui Y., Ding Y., Xu S., et al., Study on heat transfer and corrosion resistance of anodized aluminum alloy in gallium-based liquid metal. Journal of Electronic Packaging, 2019, 141(1): 011001.

[76] Deng Y.G., Liu J., Corrosion development between liquid gallium and four typical metal substrates used in chip cooling device. Applied Physics A, 2009, 95(3): 907–915.

[77] Huang K., Qiu W., Ou M., et al., An anti-leakage liquid metal thermal interface material. RSC Advances, 2020, 10(32): 18824–18829.

[78] Wang A.B., Hsieh M.C., Unveiling the missing transport mechanism inside the valveless micropump. Lab on a Chip, 2012, 12(17): 3024–3027.

[79] Huang J., Li L., Cong X., et al., Comparative experimental study of heat sinks with piezoelectric pump. Applied Thermal Engineering, 2022, 219: 119612.

[80] Tang Y., Mingze J., Ding X., et al., Experimental investigation on thermal management performance of an integrated heat sink with a piezoelectric micropump. Applied Thermal Engineering, 2019, 161: 114053.

[81] Hayes B., Govyadinov A.N., Kornilovitch P.E., Microfluidic switchboards with integrated inertial pumps. Microfluidics and Nanofluidics, 2018, 22(2): 1–9.

[82] Kornilovitch P.E., Govyadinov A.N., Markel D.P., et al., One-dimensional model of inertial pumping. Physical Review E, 2012, 87: 023012.

[83] Yeh H.C., Yang R.J., Luo W.J., Analysis of traveling-wave electro-osmotic pumping with double-sided electrode arrays. Physical Review E, 2011, 83(5): 056326.

[84] Pavlic A., Harshbarger C.L., Rosenthaler L., et al., Sharp-edge-based acoustofluidic chip capable of programmable pumping, mixing, cell focusing, and trapping. Physics of Fluids, 2023, 35(2): 022006.

[85] Kumar M., Mansukhani J., Tripathy A., et al., Biomimetic micropump: Leveraging a novel propagative rhythmic membrane function. Physics of Fluids, 2023, 35(4): 042014.

[86] Zhang H., Jiang C., Zhang Z., et al., A study on thermal performance of a pump-assisted loop heat pipe with ammonia as working fluid. Applied Thermal Engineering, 2020, 175: 115342.

[87] Karmozdi M., Afshin H., Shafii M.B., Electrical analogies applied on MMR micropump. Sensors and Actuators A: Physical, 2020, 301: 111675.

[88] Tang S.Y., Khoshmanesh K., Sivan V., et al., Liquid metal enabled pump. Proceedings of the National Academy of Sciences, 2014, 111(9): 3304–3309.

[89] Tang S.Y., Sivan V.P., Khoshmanesh K., et al., Electrochemically induced actuation of liquid metal marbles. Nanoscale, 2013, 5(13): 5949–5957.

[90] Dacuycuy S., Shiroma W., Ohta A., Electrocapillary actuation of liquid metal in microchannels. Micromachines, 2022, 13(4): 572.

[91] Singh N., Khandelwal M.K., Finite-amplitude instability of magnetohydrodynamic mixed convection flow of liquid metals in a vertical channel. Physics of Fluids, 2023, 35(5): 054112.

[92] Zhang X.D., Zhou Y.X., Liu J., A novel layered stack electromagnetic pump towards circulating metal fluid: Design, fabrication and test. Applied Thermal Engineering, 2020, 179: 115610.

[93] Sun P., Liu C.K., He Z.Z., A compact double-spiral electromagnetic pump for liquid metal cooling. Annals of Nuclear Energy, 2023, 180: 109486.

[94] Yao L., Li X.B., Zhang H.N., et al., A novel halbach array electromagnetic pump for liquid metal flow: Design proposal and performance analysis. Annals of Nuclear Energy, 2023, 183: 109641.

[95] Liu C., He Z., High heat flux thermal management through liquid metal driven with electromagnetic induction pump. Frontiers in Energy, 2022, 16(3): 460–470.

[96] Ye J., Qin P., Xing Z.R., et al., Liquid metal hydraulic actuation and thermal management based on rotating permanent magnets driven centrifugal pump. International Communications in Heat and Mass Transfer, 2022, 139: 106472.

[97] Yerasimou Y., Pickert V., Ji B., et al., Liquid metal magnetohydrodynamic pump for junction temperature control of power modules. IEEE Transactions on Power Electronics, 2018, 33(12): 10583–10593.

[98] Amy C., Budenstein D., Bagepalli M., et al., Pumping liquid metal at high temperatures up to 1,673 kelvin. Nature, 2017, 550(7675): 199–203.

[99] Liu H., Yi Y., Zhang Z., et al., Influence of structural parameters on performance of annular linear induction electromagnetic pump. Electric Machines and Control, 2024, 28(4): 92.

[100] Fiore M., Koloszar L., Fare C., et al., Physics-constrained machine learning for thermal turbulence modelling at low Prandtl numbers. International Journal of Heat and Mass Transfer, 2022, 194: 122998.

[101] Cenaiko S., Lijnse T., Dalton C., Multiphase actuation of AC electrothermal micropump. Micromachines, 2023, 14(4): 758.

[102] Watanabe M., Yoshida K., Kim J.W., et al., Three-dimensional AC electroosmotic micropump with high power density. Journal of Micromechanics and Microengineering, 2023, 33: 105008.

[103] Echouchene F., Al-shahrani T., Belmabrouk H., Simulation of slip the velocity effect in an AC electrothermal micropump. Micromachines, 2020, 11(9): 825.

[104] Ma T., Sun S., Li B., Chu J., Piezoelectric peristaltic micropump integrated on a microfluidic chip. Sensors and Actuators A: Physical, 2019, 292: 90–96.

[105] Mi S., Haitao P., Shengyue X., Sun W., A minimized valveless electromagnetic micropump for microfluidic actuation on organ chips. Sensors and Actuators A: Physical, 2020, 301: 111704.

[106] Zhang Z., He L., Zhou J., et al., A bi-directional valveless piezoelectric micropump based on the coanda effect. Journal of Mechanical Science and Technology, 2023, 37(2): 749–755.

[107] Lei J.C., Chang C.C., Wang C.Y., An analysis of bi-directional Stokes micropump comprising a periodic array of moving belts. Physics of Fluids, 2022, 34(12): 122005.

[108] Lee Y.S., Bhattacharjee N., Folch A., 3D-printed quake-style microvalves and micropumps. Lab on a Chip, 2018, 18(8): 1207–1214.

[109] Wu G., Jiang H., Li B., Design of a dual-stage driving circuit for piezoelectric-actuated micropump with bimorph transducer. IEEE Sensors Journal, 2022, 22(16): 16027–16035.

[110] Grötzbach G., Challenges in low-Prandtl number heat transfer simulation and modelling. Nuclear Engineering and Design, 2013, 264: 41–55.

[111] Laube T., Dietrich B., Marocco L., et al., Turbulent heat transfer in a liquid metal tube flow with azimuthally inhomogeneous heat flux. International Journal of Heat and Mass Transfer, 2022, 189: 122734.

[112] Guo W.T., Prasser H.M., Direct numerical simulation of turbulent heat transfer in liquid metals in buoyancy-affected vertical channel. International Journal of Heat and Mass Transfer, 2022, 194: 123013.

[113] Chen X.Y., Xie Y.C., Yang J.C., et al., Strong coupling of flow structure and heat transport in liquid metal thermal convection. Journal of Fluid Mechanics, 2023, 975: A21.

[114] Wang X., Li H., Yao R., et al., Thermal contact resistance optimization of press-pack IGBT device based on liquid metal thermal interface material. IEEE Transactions on Power Electronics, 2022, 37(5): 5411–5421.

[115] Zhang Y., Cao Y., Feng Y., et al., Numerical simulation of convective heat transfer for an internally cooled gas turbine using liquid metal. International Journal of Thermal Sciences, 2022, 171: 107230.

[116] Satish N., Venkatasubbaiah K., Conjugate heat transfer analysis of liquid metal turbulent flow through a horizontal channel by LES. Numerical Heat Transfer, Part A: Applications, 2020, 78(4): 140–157.

[117] Fico F., Langella I., Xia H., Large-eddy simulation of magnetohydrodynamics and heat transfer in annular pipe liquid metal flow. Physics of Fluids, 2023, 35(5): 055106.

[118] Shen Y., Peng S., Yan M., et al., Study of flow and heat transfer characteristics of lead-based liquid metals in a turbulent tube flow and the impacts of roughness. Frontiers in Energy Research, 2021.

DOI: 10.3389/fenrg.2021.634964.

[119] Meng J., Yu C., Li S., et al., Microfluidics temperature compensating and monitoring based on liquid metal heat transfer. Micromachines, 2022, 13(5): 792.

[120] Lee P.S., Garimella S.V., Liu D., Investigation of heat transfer in rectangular microchannels. International Journal of Heat and Mass Transfer, 2005, 48(9): 1688–1704.

[121] Gunnasegaran P., Mohammed H.A., Shuaib N.H., et al., The effect of geometrical parameters on heat transfer characteristics of microchannels heat sink with different shapes. International Communications in Heat and Mass Transfer, 2010, 37(8): 1078–1086.

[122] Wang H., Chen Z., Gao J., Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks. Applied Thermal Engineering, 2016, 107: 870–879.

[123] Hung T.C., Huang Y.X., Yan W.M., Thermal performance of porous microchannel heat sink: Effects of enlarging channel outlet. International Communications in Heat and Mass Transfer, 2013, 48: 86–92.

[124] Zhang M., Gao Q., Zhao Z., et al., Liquid metal manifold microchannel heat sink for ultra-high heat flux cooling. Applied Thermal Engineering, 2024, 248: 123117.

[125] Cai J., Wei Y., Song W., et al., Numerical simulation of chip heat dissipation using liquid metal. Journal of Materials and Metallurgy, 2021, 20(03): 232–238.

[126] Hu H., Chen C., Li C., et al., Experimental investigation of roll bond liquid cooling plates for server chip heat dissipation. Applied Thermal Engineering, 2023, 226: 120284.

[127] Zhang X., Feng W., Yu H., et al., Study on flow and heat transfer characteristics of liquid metal flow in narrow rectangular channels under high heat flux. Frontiers in Energy Research, 2024.

DOI: 10.3389/fenrg.2024.1350144.

[128] Zhou F., Zhou W., Qiu Q., et al., Investigation of fluid flow and heat transfer characteristics of parallel flow double-layer microchannel heat exchanger. Applied Thermal Engineering, 2018, 137: 616–631.

[129] Yu T., Guo X., Tang Y., et al., Numerical investigation of fluid flow and heat transfer in high-temperature wavy microchannels with different shaped fins cooled by liquid metal. Micromachines, 2023, 14(7): 1366.

[130] Thakre S., Pandhare A., Malwe P.D., et al., Heat transfer and pressure drop analysis of a microchannel heat sink using nanofluids for energy applications. Kerntechnik, 2023, 88(5): 543–555.

[131] Yin L., Liu H., Liu W., Capillary character and evaporation heat transfer in the wicks of high temperature liquid metal heat pipe. Applied Thermal Engineering, 2020, 175: 115284.

[132] Chen Z., Qian P., Huang Z., et al., Study on flow and heat transfer of liquid metal in the microchannel heat sink. International Journal of Thermal Sciences, 2023, 183: 107840.

[133] Luo W.J., Vishwakarma P., Hsieh C.C., et al., Microfluidic modular heat sink with improved material characteristics towards thermal management of flexible electronics. Applied Thermal Engineering, 2022, 216: 119142.

[134] Wei J., Chen N., Li L., et al., Effect of spoiler columns on heat transfer performance of aluminum nitride-based microchannel heat sink. Ceramics International, 2022, 48(24): 36226–36237.

[135] Oudebrouckx G., Nieder D., Vandenryt T., et al., Single element thermal sensor for measuring thermal conductivity and flow rate inside a microchannel. Sensors and Actuators A: Physical, 2021, 331: 112906.

[136] Oudebrouckx G., Vandenryt T., Bormans S., et al., Measuring thermal conductivity in a microfluidic device with the transient thermal offset (TTO) method. 2020 IEEE SENSORS, 2020.

DOI: 10.1109/SENSORS47125.2020.9278579.

[137] Yan H., Qian F., Jiao K., et al., Copper capillaries with lubricant-infused walls: Fabrication and drag reduction performance. Microfluidics and Nanofluidics, 2022, 26(10): 77.

[138] Deng Z., Zhang S., Ma K., et al., Numerical and experimental study on cooling high power chips of data centers using double-side cooling module based on mini-channel heat sink. Applied Thermal Engineering, 2023, 227: 120282.

[139] Alugoju U.K., Dubey S.K., Javed A., Optimization of converging and diverging microchannel heat sink for electronic chip cooling. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2020, 10(5): 817–827.

[140] Ali A.E.A., Cioncolini A., Laurence D.R., et al., Liquid lead flow-accelerated corrosion testing with the rotating cage set-up: A CFD optimisation. Annals of Nuclear Energy, 2022, 165: 108620.

[141] Almezgagi E.A., Fu Z., Huang G., et al., A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device. e-Polymers, 2023, 23(1): 20230050.

[142] Upot N.V., Fazle Rabbi K., Bakhshi A., et al., Etching-enabled ultra-scalable micro and nanosculpturing of metal surfaces for enhanced thermal performance. Applied Physics Letters, 2023, 122(3): 031603.

[143] Muhammad A., Selvakumar D., Wu J., Numerical investigation of laminar flow and heat transfer in a liquid metal cooled mini-channel heat sink. International Journal of Heat and Mass Transfer, 2020, 150: 119265.

[144] Ma J.X., Liu Z.H., Nguyen Q.K., et al., Lightweight soft conductive composites embedded with liquid metal fiber networks. Advanced Functional Materials, 2024, 34(31): 2308128.

[145] Kivanani A.N., Khalilpourazary S., Mobadersani F., Additive manufacturing for producing microchannel heat sinks. Progress in Additive Manufacturing, 2025, 10(1): 231–245.

[146] Ding M., Gallium extraction from extracting vanadium tailing slag. IOP Conference Series: Materials Science and Engineering, 2019, 493(1): 012115.

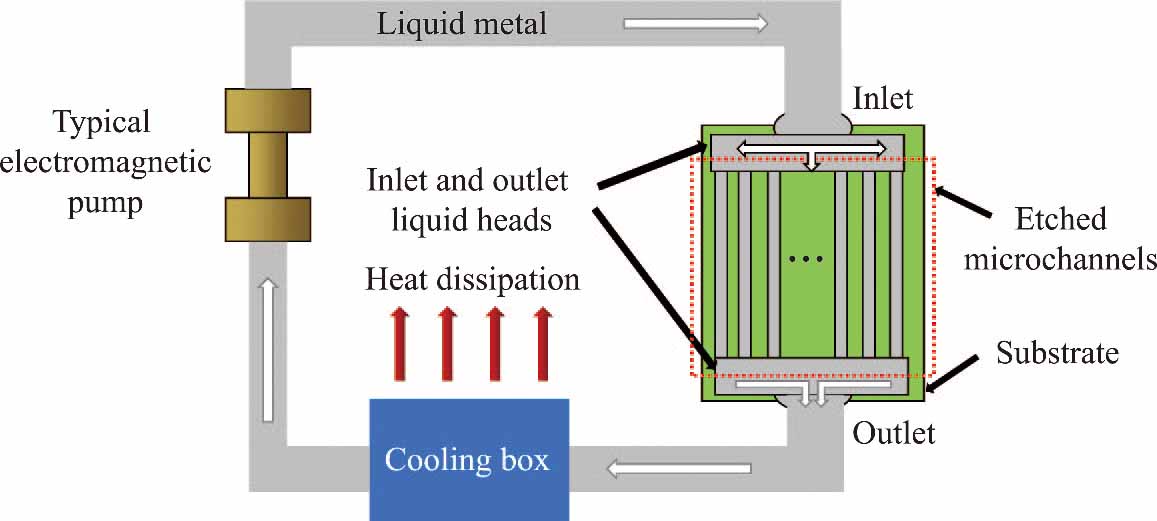

[147] Deng Z.S., Liu J., Capacity evaluation of a MEMS based micro cooling device using liquid metal as coolant. 2006 1st IEEE International Conference on Nano/Micro Engineered and Molecular Systems, 2006.

DOI: 10.1109/NEMS.2006.334738.

[148] Zhang M., Zhang X., Guo L., et al., Flow and thermal modeling of liquid metal in expanded microchannel heat sink. Frontiers in Energy, 2023, 17(6): 796–810.

[149] Yu C., Ji Y., Li Y., et al., A three-dimensional oscillating heat pipe filled with liquid metal and ammonia for high-power and high-heat-flux dissipation. International Journal of Heat and Mass Transfer, 2022, 194: 123096.

[150] Yang R., Deng Z., Li B., et al., Thermal-flow- force-electrical coupling characteristics of microchannel cooling systems in high heat flux chips. Journal of Applied Physics, 2024, 135(21): 215103.

[151] Wan W., Li H., Wang Q., et al., Research on heat dissipation of a new rectangular microchannel structure based on thermal bimetal. 2018 19th International Conference on Electronic Packaging Technology (ICEPT), 2018. DOI: 10.1109/ICEPT.2018.8480770.

[152] Yun H.R., Zhang X.X., Study on performance of micro heat dissipation system base on liquid metal. IOP Conference Series: Materials Science and Engineering, 2019, 634(1): 012013.

[153] Zhang Z., Lei J., Li F., et al., Investigation of the heat transfer characteristics of galinstan liquid metal driven by electromagnetism. Applied Thermal Engineering, 2023, 230: 120776.

[154] Wang L., Zhang X.D., Liu J., et al., Heat dissipation system based on electromagnetic-driven rotational flow of liquid metal coolant. Journal of Thermal Science and Engineering Applications, 2021, 13(6): 061023.

[155] Yang T., Foulkes T., Kwon B., et al., An integrated liquid metal thermal switch for active thermal management of electronics. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2019, 9(12): 2341–2351.

[156] Huang Y.L., Chung C.K., Lin C.F., et al., Highly thermal dissipation for large HPC package using liquid metal materials. 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), 2021. DOI: 10.1109/ectc32696.2021.00180.

[157] Zhuravlev E., Jiang J., Zhou D., et al., Extending cooling rate performance of fast scanning chip calorimetry by liquid droplet cooling. Applied Sciences, 2021, 11(9): 3813.

[158] Yan S., Yuan Q., Wu J., et al., A free-standing, phase-change liquid metal mold for 3D flexible microfluidics. Front Bioeng Biotechnol, 2022, 10: 1094294.

[159] Lin Y., Gordon O., Khan M.R., et al., Vacuum filling of complex microchannels with liquid metal. Lab Chip, 2017, 17(18): 3043–3050.

[160] Li Y., Zhang H., Li Q., et al., Texture-structure-based liquid metal filling for blind-end microchannels and its application on multi-layer chips. RSC Advances, 2023, 13(35): 24228–24236.

[161] Li P.P., Liu J., Zhou Y.X., Design of a self-driven liquid metal cooling device for heat dissipation of hot chips in a closed cabinet. Journal of Thermal Science and Engineering Applications, 2014, 6: 011009.

[162] Kalkan O., Multi-objective optimization of a liquid metal cooled heat sink for electronic cooling applications. International Journal of Thermal Sciences, 2023, 190: 108325.

[163] Zhang J., Wu J., Xie Z., et al., Suitability of embedded liquid cooling and heat generation for chips. Micromachines, 2023, 15(1): 9.

[164] Cao X., Liu H.L., Shao X.D., et al., Experimental and numerical investigation on the heat transfer enhancement for mini-channel heat sinks with tessellated fins. Applied Thermal Engineering, 2022, 211: 118353.

[165] Radmard V., Hadad Y., Rangarajan S., et al., Multi-objective optimization of a chip-attached micro pin fin liquid cooling system. Applied Thermal Engineering, 2021, 195: 117187.

[166] Wu R., Zhang X., Fan Y., et al., A bi-layer compact thermal model for uniform chip temperature control with non-uniform heat sources by genetic-algorithm optimized microchannel cooling. International Journal of Thermal Sciences, 2019, 136: 337–346.