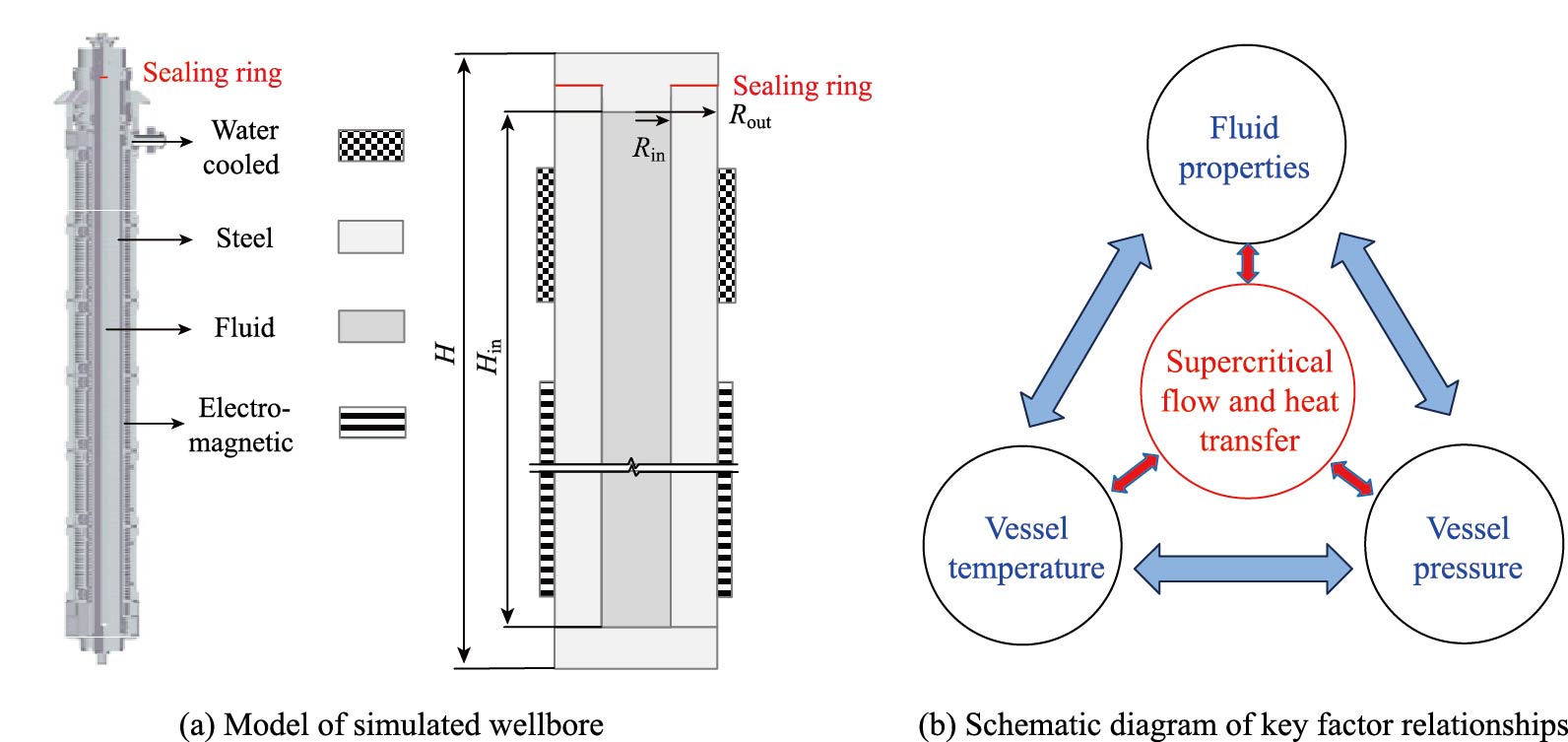

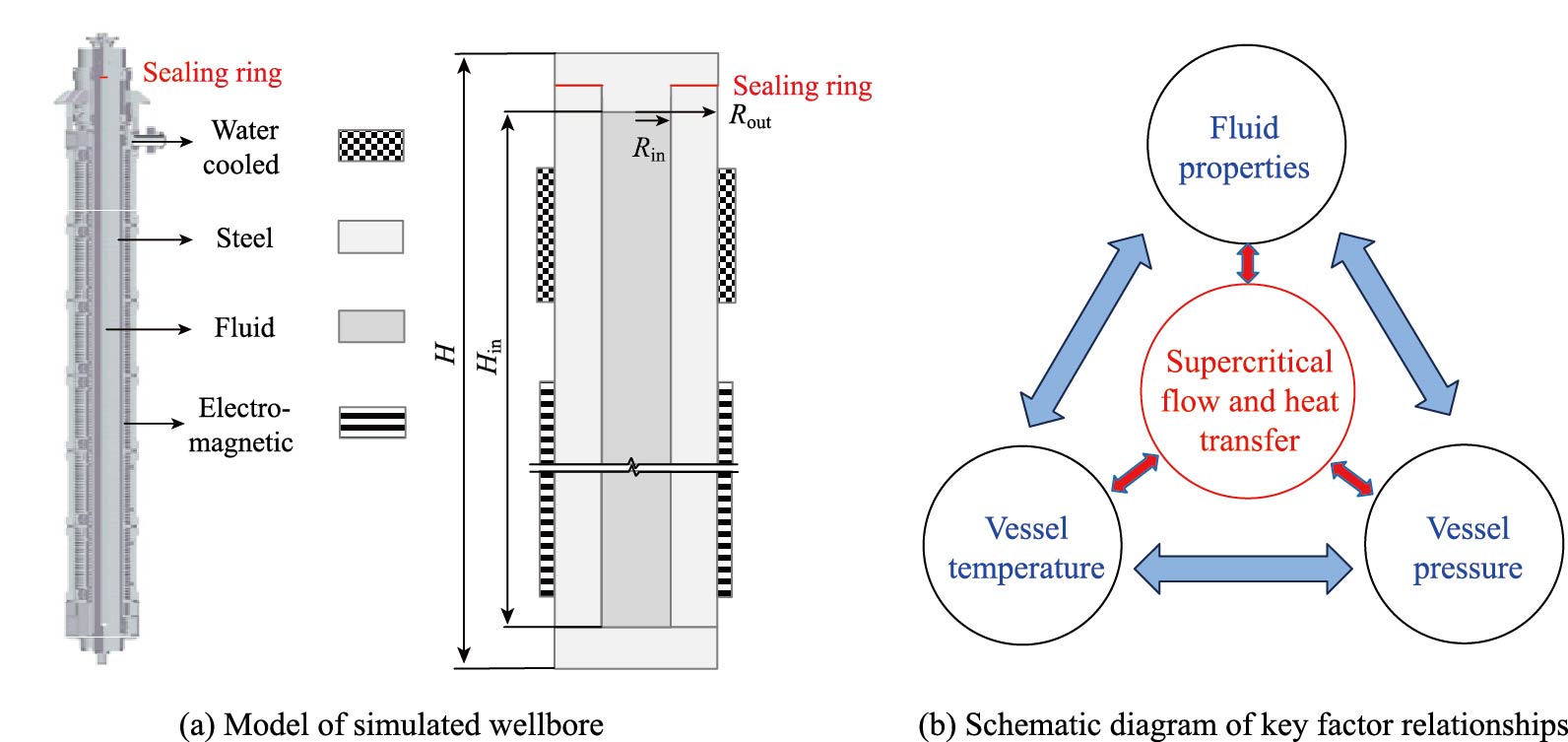

High temperature and pressure are the main challenges faced in the exploration of deep earth sciences. In order to ensure the safe drilling of high-temperature and high-pressure wells, a thick-walled simulated wellbore device is proposed and its heat transfer characteristics are studied according to the test requirements of pressure bearing exceeds 25 MPa and temperature exceeds 673.15 K. To investigate the dynamic heating process of the fluid within the cylinder, a mathematical model was developed to describe the coupled heat transfer mechanisms. This model incorporates the nonlinear properties of the fluid inside the cylinder. The results reveal that the temperature field distribution during the dynamic coupling heat transfer process is influenced by the electromagnetic induction current and the internal flow within the cylinder. During heating, the liquid transitions from a subcritical to a supercritical state. Buoyancy arising in the heating process affects the temperature distribution within the container and the formation of vortices. Incorporating a cooling system at the top of the container effectively maintains low-temperature operation in the sealing area. Additionally, the study shows that higher currents significantly increase both the final average liquid temperature and the cylinder wall temperature compared to the initial conditions. The proposed model and solution methodology provide a reliable approach for simulating fluid-structure coupled heat transfer in high-temperature, high-pressure well environments, offering a theoretical foundation for designing simulated wellbore heating systems.

CAI Tianshu

,

GUO Hualin

,

PAN Linfeng

,

ZHENG Xiaotao

. Heating Effect Evaluation of the Electromagnetic Induction Heating System at the High Temperature and Pressure Simulated Wellbore[J]. Journal of Thermal Science, 2025

, 34(6)

: 1996

-2008

.

DOI: 10.1007/s11630-025-2190-6

[1] Zhang Z., Zhao Y., Du J., et al., Research on heat transfer mechanisms in deep-water double-layer tube twin gradient drilling systems. Geoenergy Science and Engineering, 2024, 240: 213025.

DOI: 10.1016/j.geoen.2024.213025.

[2] Qin Q., Zhou K., Wei B., et al., Experimental and simulation study on deep reservoir fracturing technology: A review and future perspectives. Geoenergy Science and Engineering, 2024, 242: 213209.

DOI: 10.1016/j.geoen.2024.213209.

[3] Odiete W.E., New wellbore temperature control design for preventing failure and poor performance of logging tools in high pressure–high temperature wells. Heliyon, 2022, 8(5): e09404. DOI: 10.1016/j.heliyon.2022.e09404.

[4] Kim M., Yu S.O., Kim H.J., Analyses on fluid flow and heat transfer inside Calandria vessel of CANDU-6 using CFD. Nuclear Engineering and Design, 2006, 236(11): 1155‒1164. DOI: 10.1016/j.nucengdes.2005.10.018.

[5] Wang C., Liu H., Yu G.W., et al., Wellbore-heat -transfer-model-based optimization and control for cooling downhole drilling fluid. Petroleum Science, 2024, 21(3): 1955‒1968. DOI: 10.1016/j.petsci.2023.11.025.

[6] Chen X., Wang S., He M., et al., A comprehensive prediction model of drilling wellbore temperature variation mechanism under deepwater high temperature and high pressure. Ocean Engineering, 2024, 296: 117063. DOI: 10.1016/j.oceaneng.2024.117063.

[7] Chen X., He M., Xu M., et al., Fully transient coupled prediction model of wellbore temperature and pressure for multi-phase flow during underbalanced drilling. Geoenergy Science and Engineering, 2023, 223: 211540. DOI: 10.1016/j.geoen.2023.211540.

[8] Zhang L., Zhang Z., Wu B., et al., A fully coupled thermo-poro-elastic model predicting the stability of wellbore in deep-sea drilling. Part B: Sensitivity analysis. Geoenergy Science and Engineering, 2023, 228: 211973. DOI: 10.1016/j.geoen.2023.211973.

[9] Zhang Y., Li Y.A., Kong X.W., et al., Temperature prediction model in multiphase flow considering phase transition in the drilling operations. Petroleum Science, 2024, 21(3): 1969‒1979.

DOI: 10.1016/j.petsci.2024.01.004.

[10] Wang S., Chen X., He M., et al., Coupled modeling circulating multi-layer wellbore temperature and stress field during deepwater high-temperature and high-pressure gas well testing. Thermal Science and Engineering Progress, 2024, 47: 102356.

DOI: 10.1016/j.tsep.2023.102356.

[11] Bathija A.P., Boyd P., Martinez R., Cement sheath integrity at simulated reservoir conditions of pressure, temperature, and wellbore configuration in a laboratory setup. Geoenergy Science and Engineering, 2024, 232: 212446. DOI: 10.1016/j.geoen.2023.212446.

[12] Xu M., Fang X., Ning F., et al., Effect of hydrophilic silica nanoparticles on hydrate formation during methane gas migration in a simulated wellbore. Petroleum, 2021, 7(4): 485‒495. DOI: 10.1016/j.petlm.2021.11.004.

[13] Hou D., Zhang Z., Geng Y., et al., Experimental study on the channeling leakage properties of compact-size casing-cement sheath-stratum assembly in deep and ultra-deep wells. Process Safety and Environmental Protection, 2023, 178: 881‒892.

DOI: 10.1016/j.psep.2023.08.016.

[14] Zhang X., Jiang Z., Liao R., et al., Study on temperature distribution of perforated horizontal wellbore. Journal of Thermal Science, 2020, 29(1): 194‒205.

DOI: 10.1007/s11630-019-1247-9.

[15] Lei Y., Zhao Q., Jin H., et al., Numerical simulation of non-isothermal supercritical water flow in ground pipeline and wellbore: An interactive sensitivity analysis and injection parameters optimization. International Journal of Thermal Sciences, 2023, 193: 108467.

DOI: 10.1016/j.ijthermalsci.2023.108467.

[16] Alqahtani T., Algarni S., Askri F., Numerical investigation on performance enhancement of metal-hydride hydrogen tank using electromagnetic induction heating. Applied Thermal Engineering, 2023, 224: 120072.

DOI: 10.1016/j.applthermaleng.2023.120072.

[17] Zhang N., Luo Z., Chen X., et al., Effect of the variation of phase-transition fracturing fluid thermophysical properties on the wellbore temperature. Geoenergy Science and Engineering, 2023, 223: 211587.

DOI: 10.1016/j.geoen.2023.211587.

[18] Li J., Ye L., Investigations of water flow behaviors induced by local temperature variations through a single rough fracture for the enhanced geothermal systems. Journal of Thermal Science, 2024, 33(3): 1055‒1064. DOI: 10.1007/s11630-024-1945-9.

[19] Du X., Song Y., Xiang Y., et al., Numerical investigation on the heat transfer characteristics of supercritical water in a non-uniformly heated tube for a supercritical CFB boiler. Journal of Thermal Science, 2023, 32(5): 1807‒1818. DOI: 10.1007/s11630-023-1852-5.