[1] Pei X., Chen Q., Sun S., et al., The monolithic coupling of straight tube coriolis mass flowmeter with liquid hydrogen. Cryogenics, 2023, 129: 103625.

[2] Lai T.W., Yan S.H., Wang Y.W., et al., Numerical study on static performance of hydrodynamic bearing in high-speed liquid hydrogen centrifugal pump. International Journal of Hydrogen Energy, 2023, 48(4): 1552–1567.

[3] Moradi R., Groth K.M., Hydrogen storage and delivery: review of the state of the art technologies and risk and reliability analysis. International Journal of Hydrogen Energy, 2019, 44(23): 12254–12269.

[4] Xie F., Xia S., Zhu Y., et al., Visual experimental study of slush hydrogen production by freezing-melting method. Cryogenics, 2023, 131: 103663.

[5] Sakamoto Y., Kobayashi H., Naruo Y., et al., Investigation of the void fraction-quality correlations for two-phase hydrogen flow based on the capacitive void fraction measurement. International Journal of Hydrogen Energy, 2019, 44(33): 18483–18495.

[6] Sakamoto Y., Kobayashi H., Naruo Y., et al., Investigation of boiling hydrogen heat transfer characteristics under low-pressure conditions. Cryogenics, 2023, 131: 103652.

[7] Zhou K.M., Li S., Zhao K., et al., Efficiency control of the cooling-down process of a cryogenic helium turbo-expander for a 2 t/d hydrogen liquefier. International Journal of Hydrogen Energy, 2022, 47(69): 29794–29807.

[8] Ishimoto J., Shimada S., Coupled computing for reactive hydrogen leakage phenomena with crack propagation in a pressure tank. International Journal of Hydrogen Energy, 2022, 47(4): 2735–2758.

[9] Kapranova A.B., Lebedev A.E., Gudanov I.S., et al., Experimental study of sidewise cavitation bubbles distribution in flow channel of control valve with a butterfly gate. Chemical and Petroleum Engineering, 2023, 58: 630–636.

[10] Brennen C.E., Cavitation and bubble dynamics, second ed., Cambridge University Press, New York, USA, 2013.

[11] Bai L., Yan J., Zeng Z., et al., Cavitation in thin liquid layer: A review. Ultrason Sonochem, 2020, 66: 105092.

[12] Dular M., Petkovšek M., Cavitation erosion in liquid nitrogen. Wear, 2018, 400: 111–118.

[13] Lai T.W., Yan S.H., Zhao Q., et al., Numerical study on thermodynamic growth of single hydrogen bubble in an infinite space. International Journal of Hydrogen Energy, 2022, 47(58): 24406–24420.

[14] Krella A.K., Degradation and protection of materials from cavitation erosion: A review. Materials, 2023, 16(5): 2058.

[15] Shahlaei S., Hassankolaei M.G., MHD boundary layer of GO-H2O nano-liquid flow upon stretching plate with considering nonlinear thermal ray and joule heating effect. Heat Transfer Asian Research, 2019, 48(8): 4152–4173.

[16] Niyat Z.M., Pourfallah M., Safari S., et al., Performance assessment and optimization of a helical Savonius wind turbine by modifying the Bach’s section. SN Applied Sciences, 2021, 3(8): 739.

[17] Javidan M., Asgari M., Gholinia M., et al., Investigation of convection and radiation heat transfer of paraffinic materials and storage of thermal energy in melting process of PCMs in the cavity with transparent inner walls. Energy Reports, 2022, 8: 5522–5532.

[18] Javidan M., Asgari M., Gholinia M., et al., Thermal energy storage inside the chamber with a brick wall using the phase change process of paraffinic materials: A numerical simulation. Theoretical and Applied Mechanics Letters, 2022, 12(3): 100329.

[19] Gholinia M., Ranjbar A.A., Javidan M., et al., CFD analysis of (TiO2)-H2O nanofluids on Si-IGBT power electronic module with a new micro-nozzle model. Journal of Thermal Analysis and Calorimetry, 2022, 147(20): 11577–11589.

[20] Gholizadeh A., Pourfallah M., Gholinia M., et al., The role of nanofluids and fins in a heat exchanger on waste energy recovery from a diesel engine: An experimental and numerical study. Energy Reports, 2022, 8: 13353–13368.

[21] Nabi H., Gholinia M., Ganji D.D., Employing the (SWCNTs-MWCNTs)/H2O nanofluid and topology structures on the microchannel heatsink for energy storage: A thermal case study. Case Studies in Thermal Engineering, 2023, 42: 102697.

[22] Ghadikolaei S.S., Siahchehrehghadikolaei S., Gholinia M., et al., A CFD modeling of heat transfer between CGNPs/H2O eco-friendly nanofluid and the novel nature-based designs heat sink: hybrid passive techniques for CPU cooling. Thermal Science and Engineering Progress, 2023, 37: 101604.

[23] Zwart P.J., Gerber A.G., Belamri T., A two-phase flow model for predicting cavitation dynamics. In ICMF 2004 International Conference on Multiphase Flow, Yokohama, Japan, 2004, No. 152.

https://www.scirp.org/reference/ReferencesPapers?ReferenceID=2336724.

[24] Singhal A.K., Athavale M.M., Li H., et al., Mathematical basis and validation of the full cavitation model. Journal of Fluids Engineering, 2002, 124(3): 617–624.

[25] Sauer J., Schnerr G.H., Unsteady cavitating flow-a new cavitation model based on a modified front capturing method and bubble dynamics. American Society of Mechanical Engineers, Fluids Engineering Division (Publication) FED, 2000, 251: 1073–1079.

[26] Xu B., Feng J., Wan F., et al., Numerical investigation of modified cavitation model with thermodynamic effect in water and liquid nitrogen. Cryogenics, 2020, 106: 103049.

[27] Shalaby G.A., Abu-Bakr A.F., Growth of N-dimensional spherical bubble within viscous, superheated liquid: Analytical solution. Thermal Science, 2021, 25(1B): 503–514.

[28] Mohammadein S.A., Shalaby G.A., Abu-Bakr A.F, et al., Analytical solution of gas bubble dynamics between two-phase flow. Results Physics, 2017, 7: 2396–2403.

[29] Mohammadein S.A., Abu-Bakr A.F., The growth of vapour bubble in a superheated liquid between two phase turbulent flow. Canadian Journal of Physics, 2010, 88(5): 317–324.

[30] Abu-Nab A.K., Hakami A.M., Abu-Bakr A.F., Charged cavitation multibubbles dynamics model: Growth process. Mathematics, 2024, 12(4): 569.

[31] Abu-Nab A.K., Abu-Bakr A.F., AbuShaeer Z., Acoustic cavitation bubble under influence of frequency ultrasound: Numerical analysis. 3rd International Conference on Electronic Engineering (ICEEM), Menouf, Egypt, 2023, pp: 1–6. DOI: 10.1109/ICEEM58740.2023.10319535.

[32] Zhu J., Wang S., Qiu L., et al., Frequency characteristics of liquid hydrogen cavitating flow over a NACA0015 Hydrofoil. Cryogenics, 2018, 90: 7–19.

[33] Khan Z.A., Ahmad N., Sattar M., et al., Cell alternation algorithm for simulating bubble growth in boiling flows through volume of fluid (VOF) method in Fluent. Alexandria Engineering Journal, 2022, 61(12): 13051–13066.

[34] Ma D., Liu M., Zu Y., et al., Two-dimensional volume of fluid simulation studies on single bubble formation and dynamics in bubble columns. Chemical Engineering Science, 2012, 72: 61–77.

[35] Anderson L.M., Hold J., Hall W.J., Cavitation in liquid cryogens. 1: Venturi, national aeronautics and space administration (NASA), 1972, Washington D.C., USA, Report No. NASA-CR-2054.

http://www.researchgate.net/publication/24388908_Cavitation_in_liquid_cryogens_1_Venturi.

[36] Hord J., Cavitation in liquid cryogens. 2: Hydrofoil, national aeronautics and space administration (NASA), 1973, Washington D.C., USA, Report No. NASA-CR-2156. https://ntrs.nasa.gov/citations/19730007528.

[37] Hord J., Cavitation in liquid cryogens. 3: Ogives, national aeronautics and space administration (NASA), 1973, Washington D.C., USA, Report No. NASA-CR-2242. https://ntrs.nasa.gov/citations/19730019421.

[38] Hord J., Cavitation in liquid cryogens. 4: Combined correlations for venturi, hydrofoil, ogives, and pumps, national aeronautics and space administration (NASA), 1974, Washington D.C., USA, Report No. NASA-CR-2448. https://ntrs.nasa.gov/citations/19740026591.

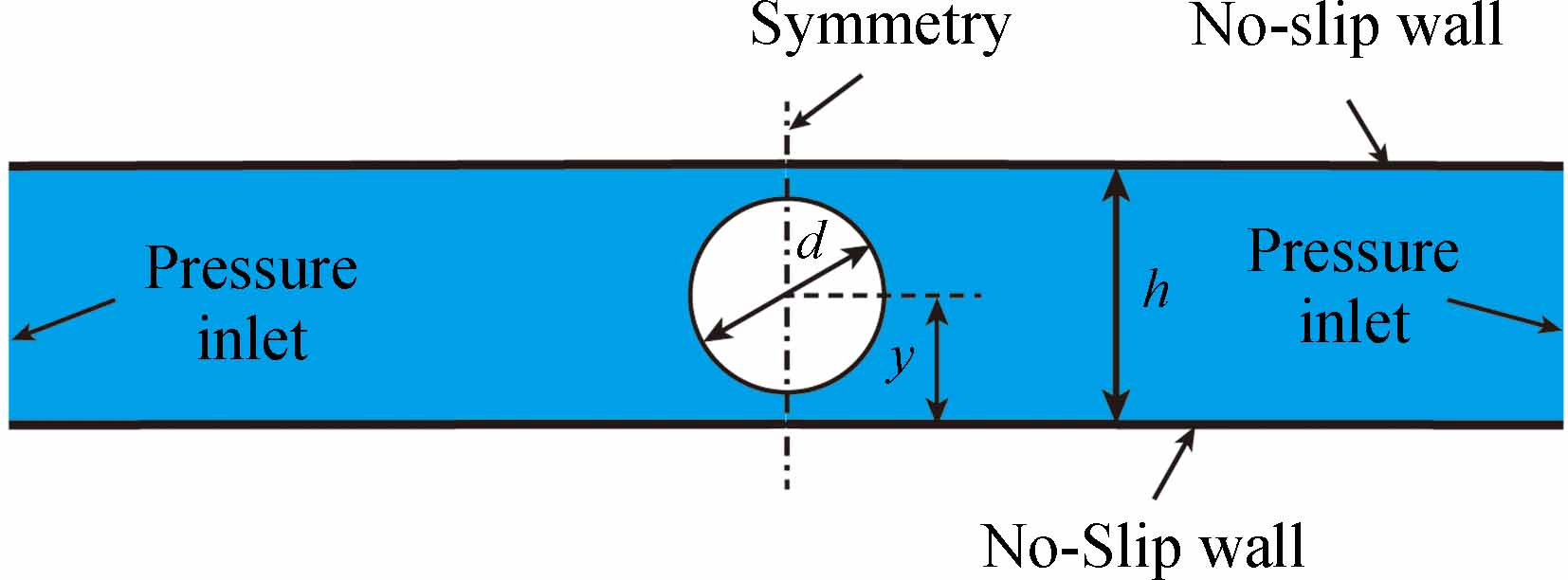

[39] Quinto-Su P.A., Lim K.Y., Ohl C.D., Cavitation bubble dynamics in microfluidic gaps of variable height. Phyical. Review E, 2009, 80(4): 047301.

[40] Gonzalez-Avila S.R., Klaseboer E., Khoo B.C., et al., Cavitation bubble dynamics in a liquid gap of variable height. Journal of Fluid Mechanics, 2011, 682, 241–260.

[41] Lai T.W., Yan S.H., Wang Y.W., et al., Experimental study on vaporous cavitation of R134a in micron clearance. Experimental Thermal and Fluid Science, 2021, 129: 110484.

[42] Gonzalez-Avila S.R., Zeng Q., Ohl C.D., et al., Jetting and shear stress enhancement from cavitation bubbles collapsing in a narrow gap. Journal of Fluid Mechanics, 2020, 884: A23.

[43] Mohammadzadeh M., Li F., Ohl C.D., Shearing flow from transient bubble oscillations in narrow gaps. Physical Review Fluids, 2017, 2(1): 014301.

[44] Azam F.I., Khoo B.C., Karri B., et al., Dynamics of an oscillating bubble in a narrow gap. Physical Review E, 2013, 88(4): 043006.

[45] Yang N., Chen J., Zhao H., et al., Explorations on the multi-scale flow structure and stability condition in bubble columns. Chemical Engineering Science, 2007, 62(24): 6978–6991.

[46] Brackbill J.U., Kothe D.B., Zemach C.A., A continuum method for modeling surface tension. Journal of Computational Physics, 1992, 100(2): 335–354.

[47] Lai T.W., Yan S.H., Zhao Q., et al., Numerical study on thermodynamic growth of single hydrogen bubble in an infinite space. International Journal of Hydrogen Energy, 2022, 47(58): 24406–24420.

[48] Yan S.H., Lai T.W., Zhao Q., et al., Numerical study on single-bubble contraction-rebound characteristics in cryogenic fluids. Applied Sciences, 2022, 12(21): 10839.

[49] Huang B., Wu Q., Wang G., Numerical investigation of cavitating flow in liquid hydrogen. International Journal of Hydrogen Energy, 2014, 39(4): 1698–1709.

[50] Cao Q., Li Y., Fang C., et al., Status quo and utilization trend of global helium resources. Frontiers Environmental Science, 2022, 10.

[51] Lai T., Yan S., Zhao Q., et al., Numerical study on thermodynamic growth of single hydrogen bubble in an infinite space. International Journal of Hydrogen Energy, 2022, 47(58): 24406–24420.

[52] Plesset M.S., Chapman R.B., Collapse of an initially spherical vapour cavity in the neighbourhood of a solid boundary. Journal of Fluid Mechanics, 1971, 47(2): 283–290.

[53] Lemmon E.W., Huber M.L., Mclinden M.O., NIST standard reference database 23: Reference fluid thermodynamic and transport properties-REFPROP. 9.0. NIST NSRDS, 2010.