[1] Dhaidan N., Hashim H., Abbas A., et al., Discharging of PCM in various shapes of thermal energy storage systems: A review. Journal of Thermal Science, 2023, 32: 1124–1154.

[2] Wang J., Yao W., Cui Z., et al., Energy, exergy, and exergoeconomic analysis of solar-driven solid oxide electrolyzer system integrated with waste heat recovery for syngas production. Journal of Thermal Science, 2023, 32: 135–152.

[3] Yan B., Lv J., Zhou S., et al., Application of optical diagnosis technology in biomass combustion. Biomass and Bioenergy, 2024, 184: 107198.

[4] Lin J., Li Y., Qian Y., et al., Effectiveness of government subsidies for biomass-based industries: Incorporating the feedstock acquisition process. Energy Policy, 2024, 192: 114251.

[5] Emmanuel O., Ezeji T.C., Utilization of biomass-based resources for biofuel production: A mitigating approach towards zero emission. Sustainable Chemistry One World, 2024, 2: 100007.

[6] Knápek J., Starý O., Vávrová K., et al., Modelling the impact of business risk on the competitiveness of purpose-grown biomass of annual and perennial crops. Renewable and Sustainable Energy Reviews, 2024, 202: 114707.

[7] Burrington J.D., Renewable energy technical potential performance for zero carbon emissions. ACS Omega, 2024, 9(24): 25841–25858.

[8] Antar M., Lyu D., Nazari M., et al., Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization. Renewable and Sustainable Energy Reviews, 2021, 139: 110691.

[9] Zhao X., Li R., Liu W., et al., Estimation of crop residue production and its contribution to carbon neutrality in China. Resources, Conservation and Recycling, 2024: 203: 107450.

[10] Jiang X., Liu J., Ren J., et al., Corn straw supported high-performance phase change composites: Strategy to turn agricultural residues into high efficient and stable thermal energy storage materials. Materials Today Sustainability, 2023, 24: 100571.

[11] Xiong Y., Yao H., Lu C., et al., Multi-physical field coupling modeling of microwave heating and reduction behavior of zinc oxide. Chemical Engineering Journal, 2024, 495: 153716.

[12] Hu J., Jiang B., Wang J., et al., Physicochemical characteristics and pyrolysis performance of corn stalk torrefied in aqueous ammonia by microwave heating. Bioresource Technology, 2019, 274: 83–88.

[13] Shi J., Pu Y., Yang B., et al., Comparison of microwaves to fluidized sand baths for heating tubular reactors for hydrothermal and dilute acid batch pretreatment of corn stover. Bioresource Technology, 2011, 102(10): 5952–5961.

[14] Abedin A., Bai X., Muley P., Microwave-assisted catalytic gasification of mixed plastics and corn stover for low tar, hydrogen-rich syngas production. International Journal of Hydrogen Energy, 2024, 77: 69–83.

[15] Nazari M., Aguilar M., Ghislain T., et al., Microwave-assisted pyrolysis of biomass waste for production of high-quality biochar: Corn stover and hemp stem case studies. Biomass and Bioenergy, 2024, 187: 107302.

[16] Cui L., Qin N., Li H., et al., Heating performances of corn straw particles in a microwave chamber. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2023, 45: 7186–7197.

[17] Zhao W., Zhang Y., Cui L., et al., Energy and exergy performances of low-density polyethylene plastic particles assisted by microwave heating. Environmental Science and Pollution Research, 2024, 31: 57559–57569.

[18] Ellison C., McKeown M.S., Trabelsi S., et al., Dielectric properties of biomass/biochar mixtures at microwave frequencies. Energies, 2017, 10(4): 502.

[19] Shkal F., Lopez S., Slocombe D., et al., Microwave characterization of activated carbons. Journal of Computer and Communications, 2018, 6: 112–123.

[20] Fukushima J., Tsubaki S., Matsuzawa T., et al., Effect of aspect ratio on the permittivity of graphite fiber in microwave heating. Materials, 2017, 11(1): 169.

[21] Fan S., Zhang Y., Cui L., et al., Conversion of polystyrene plastic into aviation fuel through microwave-assisted pyrolysis as affected by iron-based microwave absorbents. ACS Sustainable Chemistry and Engineering, 2023, 11(3): 1054–1066.

[22] Fan S., Liu Y., Zhang Y., et al., Microwave-assisted pyrolysis of plastics for aviation oil production: energy and economic analyses. Frontiers of Chemical Science and Engineering, 2024, 18(7): 81.

[23] Parvej, Sharma A.K., Effect of insulation materials and power on microwave heating characteristics of SiC susceptor under material-specific parametric conditions. International Journal of Thermal Sciences, 2024, 204: 109229.

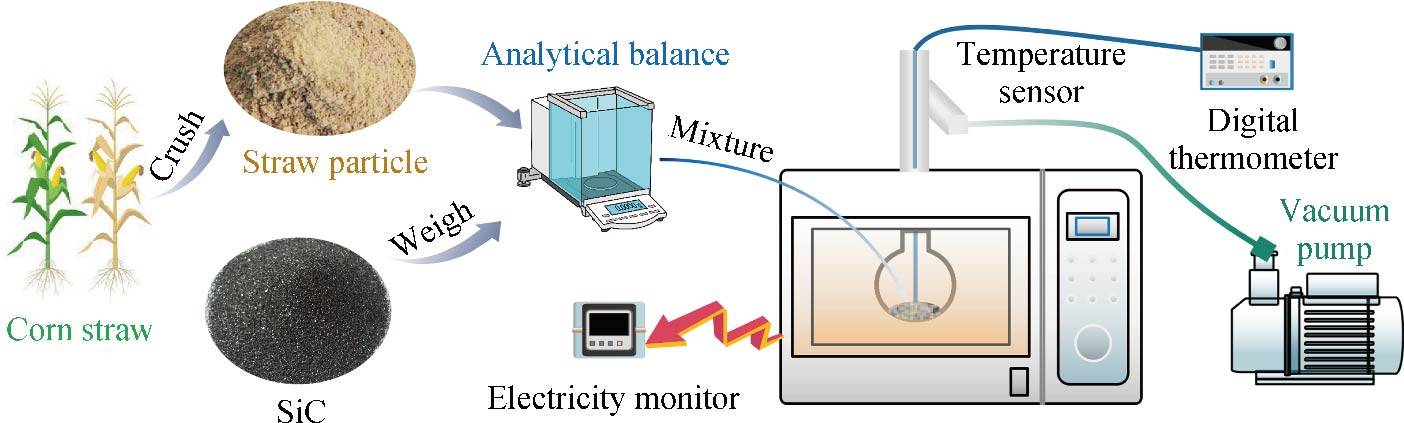

[24] Cui L., Zhao W., Mostafa E., et al., Heating performances of corn straw particle with/without SiC particle in a microwave chamber. Environmental Science and Pollution Research, 2024, 31: 57533–57541.

[25] Cui Y., Zhang Y., Cui L., et al., Microwave-assisted pyrolysis of polypropylene plastic for liquid oil production. Journal of Cleaner Production, 2023, 411: 137303.

[26] Cui L., Zhang Y., Shi C., et al., Describing the microwave heating performances of the main constitutes of biomass. Energy, 2024, 302: 131873.

[27] Fu W., Dai J., Zhang Y., et al., Heating performances of high density polyethylene (HDPE) plastic particles in a microwave chamber. Sustainable Energy Technologies and Assessments, 2021, 48: 101581.

[28] Yang M., Li X., Yuan J., et al., Energy and exergy analysis of a cooling/power cogeneration ejector refrigeration system. Journal of Thermal Science, 2022, 31: 448–462.

[29] Wang J., Yao W., Cui Z., et al., Energy, exergy, and exergoeconomic analysis of solar-driven solid oxide electrolyzer system integrated with waste heat recovery for syngas production. Journal of Thermal Science, 2023, 32: 135–152.

[30] Manatura K., Lu J.H., Wu K.T., et al., Exergy analysis on torrefied rice husk pellet in fluidized bed gasification. Applied Thermal Engineering, 2017, 111: 1016–1024.

[31] Ke C., Liu T., Zhang Y., et al., Energy absorption performances of silicon carbide particles during microwave heating process. Chemical Engineering & Processing: Process Intensification, 2022, 172: 108796.

[32] Dutta A., Ganguly R., Sarkar L., Energy and exergy analysis of an externally fired gas turbine (EFGT) cycle integrated with biomass gasifier for distributed power generation. Energy, 2010, 35: 341–350.