[1] Jaganmohan M., Global market value of gas turbine industry 2016-2021. Bruna Alves, 2024.

[2] Kline S.J., Abbott D.E., Fox R.W., Optimum design of straight-walled diffusers. Journal of Basic Engineering, 1959, 81(3): 321–329.

[3] Sovran G., Experimentally determined optimum geometries for rectlinear diffusers with rectangular, conical or annular cross section. Fluid Mechanics of Internal Flow, 1967, 117(2): 231–239.

[4] Kumar D.S., Kumar K.L., Effect of swirl on pressure recovery in annular diffusers. Journal of Mechanical Engineering Science, 1980, 22(6): 305–313.

[5] Babu M., Bhatia D., Shukla R.K., et al., Effect of turbine tip leakage flows on exhaust diffuser performance. Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, British Columbia, Canada, 2011, 7: 609–618.

DOI: https://doi.org/10.1115/GT2011-45457.

[6] Babu M., Shukla R.K., Maru A., et al., Boundary layer control in turbine exhaust diffusers using casing injection and design modifications. Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 2012, 8: 1069–1079.

DOI: https://doi.org/10.1115/GT2012-68387.

[7] Zimmermann C., Stetter H., Experimental determination of the flow field in the tip region of a LP-steam turbine. Proceedings of the ASME 1993 International Gas Turbine and Aeroengine Congress and Exposition, Cincinnati, Ohio, USA, 1993, 1: 1–8.

DOI: https://doi.org/10.1115/93-GT-106.

[8] Kluß D., Wiedermann A., Volgmann W., Impact of gas turbine outflow on diffuser performance-a numerical study. Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 2004, 5: 111–119. DOI: https://doi.org/10.1115/GT2004-53043.

[9] Vassiliev V., Irmisch S., Abdel-wahab S., et al., Impact of the inflow conditions on the heavy-duty gas turbine exhaust diffusers performance. Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 2010, 7: 1401–1412.

DOI: https://doi.org/10.1115/GT2010-22840.

[10] Zhang L., Kang J., Lang J., et al., Stall evolution mechanism of a centrifugal compressor with a wide-long vaneless diffuser. Journal of Thermal Science, 2024, 33(3): 899–913.

[11] Kuschel M., Drechsel B., Kluß D., et al., Influence of turbulent flow characteristics and coherent vortices on the pressure recovery of annular diffusers: Part A—Experimental results. Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, Quebec, Canada, 2015, 2A: V02AT38A001.

DOI: https://doi.org/10.1115/GT2015-42476

[12] Drechsel B., Müller C., Herbst F., et al., Influence of turbulent flow characteristics and coherent vortices on the pressure recovery of annular diffusers: part B—Scale-resolving simulations. Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, Quebec, Canada, 2015, 2A: V02AT38A010.

DOI: https://doi.org/10.1115/GT2015-42477.

[13] Steven S.J., Williams Q.J., The influence of inlet conditions on the performance of annular diffusers. Journal of Fluids Engineering, 1980, 102(3): 357–363.

[14] Vassiliev V., Irmisch S., Florjancic S., CFD analysis of industrial gas turbine exhaust diffusers. Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, the Netherlands, 2002, 5: 995–1013. DOI: https://doi.org/10.1115/GT2002-30597.

[15] Vassiliev V., Irmisch S., Clarideg M., et al., Experimental and numerica investigation of the impact of swirl on the performance of industrial gas turbines exhaust diffusers. Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, Georgia, USA, 2003, 6: 19–29.

DOI: https://doi.org/10.1115/GT2003-38424.

[16] Opilat V., Seume J.R., The effect of the operating conditions of the last turbine stage on the performance of an axial exhaust diffuser. Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, British Columbia, Canada, 2011, 7: 695–704. DOI: https://doi.org/10.1115/GT2011-45668.

[17] Olaf S., Joerg R.S., Influence of rotating blade wakes on separation in turbine exhaust diffusers. Journal of Thermal Science, 2008, 17(1): 42–49.

[18] Flelge H.U., Rless W., Seume J., Swirl and tip leakage flow interaction with struts in axial diffusers. Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air. Amsterdam, the Netherlands, 2002, 5: 871–878. DOI: https://doi.org/10.1115/GT2002-30491.

[19] Brown K., Guillot S., Ng W., et al., Experimental investigation of gas turbine axial diffuser performance: Part I – parametric analysis of influential variables. Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Virtual, Online, 2020, 2D: V02DT36A016.

DOI: https://doi.org/10.1115/GT2020-15299.

[20] Brown K., Guillot S., Ng W., et al., Experimental investigation of gas turbine axial diffuser performance: Part II — Effect of inlet flow profiles at on- and off-design conditions. Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference and Exposition, Virtual, Online, 2021, 2C: V02CT35A001, DOI: https://doi.org/10.1115/GT2021-03719.

[21] Roman Z.P., Joerg R.S., Interaction between struts and swirl flow in gas turbine exhaust diffusers. Journal of Thermal Science, 2005, 14(4): 314–320.

[22] Harris H., Piñeiro I., Norris T., A performance evaluation of a three splitter diffuser and vaneless diffuser installed on the power turbine exhaust of a TF40B gas turbine. Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 1998, 2: V002T03A011.

DOI: https://doi.org/10.1115/98-GT-284.

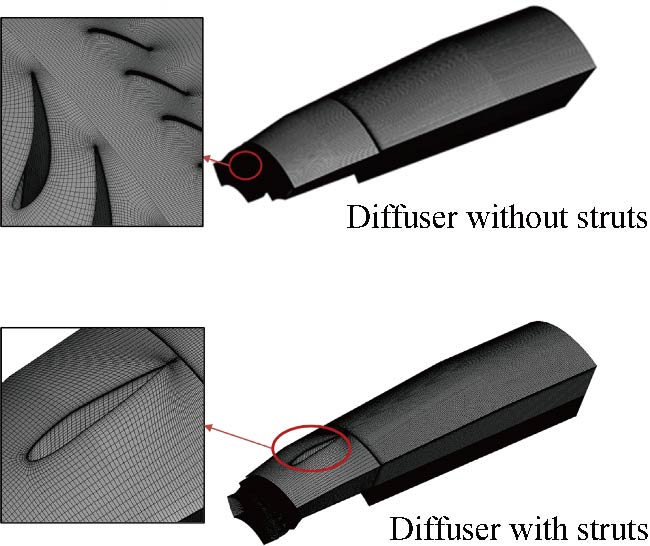

[23] Stefano U., Umberto D., Experimental performance analysis of an annular diffuser with and without struts. Experimental Thermal and Fluid Science, 2000, 22(3–4): 183–195.

[24] Stefano U., Umberto D., Flow development and turbulence length scales within an annular gas turbine exhaust diffuser. Experimental Thermal and Fluid Science, 2000, 22(1–2): 55–70.

[25] Prakash R., Christopher D., Kumarrathinam K., CFD analysis of flow through a conical exhaust diffuser. International Journal of Research in Engineering and Technology, 2014, 3(11): 239–248.

[26] Fric T.F., Villarreal R., Auer R.O., et al., Vortex shedding from struts in an annular exhaust diffuser. American Society of Mechanical Engineers, 1998, 120(1): 186–192.

[27] Dong Y., Li Z., Li J., An investigation of the tapered strut on aerodynamic performance of the exhaust diffuser under different swirls. Engineering for Gas Turbines and Power, 2022, 144(1): 011006–011017.

[28] Pradeep A.M., Bhaskar R., Vaibhav V., et al., Study of gas turbine exhaust diffuser performance and its enhancement by shape modifications. Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 2010, 7: 1101–1110.

DOI: https://doi.org/10.1115/GT2010-22088.

[29] Cerantola D.J., Birk A.M., Numerically optimizing an annular diffuser using a genetic algorithm with three objectives. Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 2011, 8: 1033–1042.

DOI: https://doi.org/10.1115/GT2012-68205.

[30] ANSYS, Inc. ANSYS ICEM CFD 2021 R1. Mesh Generation Software. ANSYS, Inc, PA, Canonsburg, 2021.

[31] NUMECA International. AutoGrid 5. Mesh generation software, Version 10.2. In A. Smith (Ed.), Computational Fluid Dynamics: Techniques and Applications, Springer, Berlin, 2016.

[32] Mihailowitsch M., Schatz M., Vogt D.M., Numerical investigations of an axial exhaust diffuser coupling the last stage of a generic gas turbine. Journal of Engineering for Gas Turbines and Power, 2019, 141(3): 031025.