[1] Zhang W.K., Kong W.J., Sui C.J., et al., Effect of hydrogen-rich fuels on turbulent combustion of advanced gas turbine. Journal of Thermal Science, 2022, 31: 561–570.

[2] Huang F.J., Kong W.J., Experimental investigation of operating characteristics and thermal balance of a miniature free-piston linear engine. Applied Thermal Engineering, 2020, 178: 115608.

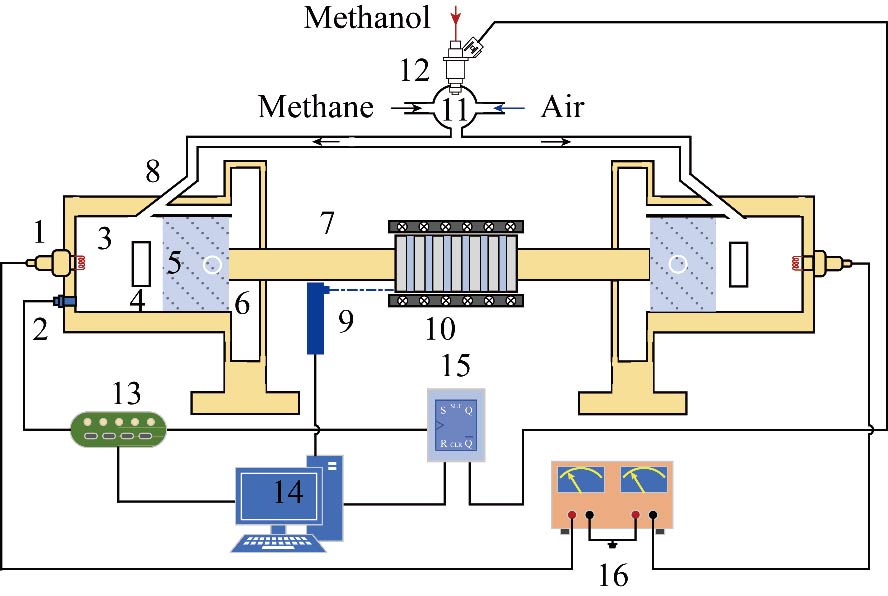

[3] Huang F.J., Kong W.J., Experimental study on the operating characteristics of a reciprocating free piston linear engine. Applied Thermal Engineering, 2019, 161: 114131.

[4] Mishra M.P., Assessment of performance, combustion and emissions characteristics of methanol-diesel dual-fuel compression ignition engine: A review. Journal of Traffic and Transportation Engineering (English Edition), 2021, 8(5): 638–680.

[5] Chen Z.M., Wang L., Yuan X.A., et al., Experimental investigation on performance and combustion characteristics of spark-ignition dual-fuel engine fueled with methanol/natural gas. Applied Thermal Engineering, 2019, 150: 164–174.

[6] Zhen X.D., Li X.Y., Wang Y., et al., Effects of the initial flame kernel radius and EGR rate on the performance, combustion and emission of high-compression spark-ignition methanol engine. Fuel, 2020, 262: 116633.

[7] Zhang M.M., Hong W., Xie F.X., et al., Effects of diluents on cycle-by-cycle variations in a spark ignition engine fueled with methanol. Energy, 2019, 182: 1132–1140.

[8] Ming Z.Y., Liu B., Zhang X., et al., Study of methanol spray flame structure and combustion stability mechanisms by optical phenomenology and chemical kinetics. Fuel Processing Technology, 2023, 252: 107947.

[9] Li L.P., Wei J.N., Liu H.F., et al., The exergy analysis of low carbon or carbon free fuels: Methane, methanol and hydrogen under engine like conditions. Fuel Processing Technology, 2023, 252: 107975.

[10] Liu H.F., Zhang X.T., Zhang Z., et al., Experimental and numerical study on the performances of a free-piston engine generator using ammonia and methane fuel mixtures. Fuel, 2023, 341: 127684.

[11] Liu H.F., Ampah J.D., Zhao Y., et al., A perspective on the overarching role of hydrogen, ammonia, and methanol carbon-neutral fuels towards net zero emission in the next three decades. Energies, 2023, 16(1): 280.

[12] Verhelst S., Turner J., Sileghem L., et al., Methanol as a fuel for internal combustion engines. Progress in Energy and Combustion Science, 2019, 70: 43–88.

[13] Awad O.I., Mamat R., Ibrahim T.K., et al., Overview of the oxygenated fuels in spark ignition engine: environmental and performance. Renewable and Sustainable Energy Reviews, 2018, 91: 394–408.

[14] Awad O.I., Mamat R., Ali O.M., et al., Alcohol and ether as alternative fuels in spark ignition engine: a review. Renewable and Sustainable Energy Reviews, 2018, 82: 2586–2605.

[15] Chen Z.M., He J.J., Chen H., et al., Comparative study on the combustion and emissions of dual-fuel common rail engines fueled with diesel/methanol, diesel/ethanol, and diesel/n-butanol. Fuel, 2021, 304: 121360.

[16] Panda K., Ramesh A., Diesel injection strategies for reducing emissions and enhancing the performance of a methanol based dual fuel stationary engine. Fuel, 2021, 289: 119809.

[17] Canakci M., Ozsezen A.N., Alptekin E., et al., Impact of alcohol-gasoline fuel blends on the exhaust emission of an SI engine. Renew Energy, 2013, 52: 111–117.

[18] Prasad B.N., Pandey J.K., Kumar G.N., Effect of hydrogen enrichment on performance, combustion, and emission of a methanol fueled SI engine. International Journal of Hydrogen Energy, 2021, 46(49): 25294–25307.

[19] Chen Z.M., Wang L., Zhang Q.G., et al., Effects of spark timing and methanol addition on combustion characteristics and emissions of dual-fuel engine fuelled with natural gas and methanol under lean-burn condition. Energy Conversion and Management, 2019, 181: 519–527.

[20] Du N., Kong W.J., Experimental and numerical studies of a microscale internal combustion swing engine (MICSE). Journal of Thermal Science, 2021, 30: 1705–1717.

[21] Huang F.J., Xiao H.H., Guo S.M., et al., Effect of disturbances on the operation process of a methane-fueled free-piston engine generator. Journal of Thermal Science, 2023, 32: 881–896.

[22] Nandkumar S., Two-stroke linear engine. West Virginia University, Morgantown, USA, 1998.

[23] Jia B.R., Tian G.H., Feng H.H., et al., An experimental investigation into the starting process of free-piston engine generator. Applied Energy, 2015, 157: 798–804.

[24] Woo Y., Lee Y., Lee Y., The performance characteristics of a hydrogen-fuelled free piston internal combustion engine and linear generator system. International Journal of Low-Carbon Technologies, 2009, 4(1): 36–41.

[25] Huang F.J., Kong W.J., Effect of hydrogen addition on the operating characteristics of a free piston linear engine. International Journal of Hydrogen Energy, 2020, 45(30): 15402–15413.

[26] Huang F.J., Kong W.J., Effects of hydrogen addition on combustion characteristics of a free-piston linear engine with glow-assisted ignition. International Journal of Hydrogen Energy, 2021, 46(44): 23040–23052.

[27] Huang F.J., Guo S.M., Wang L.J., et al., Experimental and numerical study on the performances of a free-piston engine generator using ammonia and methane fuel mixtures. Fuel, 2023, 341: 127654.

[28] Pichler C.S., Nilsson E.J.K., Reduced kinetic mechanism for methanol combustion in spark-ignition engines. Energy & Fuel, 2018, 32(12): 12805–12813.

[29] Chen Z., Yang F., Xue S., et al., Impact of higher n-butanol addition on combustion and performance of GDI engine in stoichiometric combustion. Energy Conversion and Management, 2015, 106: 385–392.

[30] Li Y., Gong J.K., Deng Y.W., et al., Experimental comparative study on combustion, performance and emissions characteristics of methanol, ethanol and butanol in a spark ignition engine. Applied Thermal Engineering, 2017, 115: 53–63.

[31] Eng J.A., Characterization of pressure waves in HCCI combustion. SAE Technical Paper, 2002, 2002-01-2859.

[32] Sjöberg M., Dec J.E., Babajimopoulos A., et al., Comparing enhanced natural thermal stratification against retarded combustion phasing for smoothing of HCCI heat release rates. SAE Technical Paper, 2004: 2004-01-2994.

[33] Jarquin-Lopez G., Polupan G., Toledo-Velazquez M., et al., Analytical and experimental research for decreasing nitrogen oxides emissions. Applied Thermal Engineering, 2009, 29(8–9): 1614–1621.