[1] Curran S., Onorati A., Payri R., et al., The future of ship engines: Renewable fuels and enabling technologies for decarbonization. International Journal of Engine Research, 2024, 25(1): 85–110.

[2] Gao C., Li J., Li Y., et al., Research progress on Passive NOx Adsorbers (PNAs) for diesel vehicles. Energy Environmental Protection, 2025, 39(2): 1–15.

[3] Huo J., Li X., Zhang D., Effects of gasoline additives on engine combustion and emissions characteristics. Energy Environmental Protection, 2023, 37(2): 178–186.

[4] Wiesmann F., Qiu Z., Han D., et al., Numerical study of novel OME1-6 combustion mechanism and spray combustion at changed ambient environments. Frontiers in Energy, 2024, 18(4): 483–505.

[5] Chu S., Wang Q., Climate change and innovative paths to a more sustainable future. Frontiers in Energy, 2024, 18(6): 717–726.

[6] Fridell E., Salberg H., Salo K., Measurements of emissions to air from a marine engine fueled by methanol. Journal of Marine Science and Application, 2021, 20(1): 138–143.

[7] Sakai S., Rothamer D., Knock-limited combustion of ethanol-, isobutanol-, and 2-methyl-3-buten-2-ol-gasoline blends in a direct-injected spark-ignition engine. International Journal of Engine Research, 2023, 24(9): 4251–4275.

[8] Fan Y., Duan Y., Han D., et al., Influences of isomeric butanol addition on anti-knock tendency of primary reference fuel and toluene primary reference fuel gasoline surrogates. International Journal of Engine Research, 2021, 22(1): 39–49.

[9] Li L., Qiu Z., Wang C., et al., Experimental and kinetic modeling study on ammonia/ polyoxymethylene dimethyl ether 2 oxidation in a jet-stirred reactor. Fuel, 2024, 359: 130528.

[10] Zhang J., Huang Z., Han D., Exergy losses in auto-ignition processes of dme and alcohol blends. Fuel, 2018, 229: 116–125.

[11] Zhang Q., Wu H., Mi S., et al., Experimental investigation on collision characteristics of dual-spray with different physical-chemical fuel properties: A case study of butanol-biodiesel fuel combination. International Journal of Engine Research, 2023, 24(8): 3588–3601.

[12] Han D., Duan Y., Wang C., et al., Experimental study of the two-stage injection process of fatty acid esters on a common rail injection system. Fuel, 2016, 163: 214–222.

[13] Hur J., Park J., Landon R.S., et al., Optimization of a reactive distillation process for the synthesis of dialkyl carbonate considering side reactions. Industrial & Engineering Chemistry Research, 2019, 58(38): 17898–17905.

[14] Yang G., Wang Q., Li L., et al., Exploring dialkyl carbonate as a low-carbon fuel for combustion engines: An overview. Fuel, 2025, 386: 134221.

[15] Pan M.Z., Qian W.W., Zheng Z.Y., et al., The potential of dimethyl carbonate (DMC) as an alternative fuel for compression ignition engines with different EGR rates. Fuel, 2019, 257: 115920.

[16] Qian W., Huang H., Pan M., et al., Effects of 2-ethylhexyl nitrate and post-injection strategy on combustion and emission characterizes in a dimethyl carbonate/diesel blending engine. Fuel, 2020, 263: 116687.

[17] Wang Q., Ni J., Huang R., The potential of oxygenated fuels (n-octanol, methylal, and dimethyl carbonate) as an alternative fuel for compression ignition engines with different load conditions. Fuel, 2022, 309: 122129.

[18] Huang Z.H., Jiang D.M., Zeng K., et al., Combustion characteristics and heat release analysis of a direct injection compression ignition engine fuelled with diesel-dimethyl carbonate blends. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2003, 217(7): 595–605.

[19] Li X., Huang Z., Qiao X., et al., Flexible fuel engine based on multi-combustion control technologies. Chinese Science Bulletin, 2005, 50(2): 185–189.

[20] Kumar Rajesh B., Saravanan S., Partially premixed low temperature combustion using dimethyl carbonate (DMC) in a DI diesel engine for favorable smoke/NOx emissions. Fuel, 2016, 180: 396–406.

[21] Fan C., Guan Z., Wei J., et al., An assessment of soot chemical property from a modern diesel engine fueled with dimethyl carbonate-diesel blends. Fuel, 2022, 309: 122220.

[22] Li M.D., Zhao Y., Fang J., et al., Effect of dimethyl carbonate on the micromorphology and structure of combustion particles from diesel engines. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2019, 42(9): 1155–1165.

[23] Aguado-Deblas L., Hidalgo-Carrillo J., Bautista F.M., et al., Biofuels from diethyl carbonate and vegetable oils for use in triple blends with diesel fuel: Effect on performance and smoke emissions of a diesel engine. Energies, 2020, 13(24): 6584.

[24] Bridjesh P., Geetha N.K., Effect of diethyl carbonate as additive to waste plastic oil on performance and emission of a diesel engine. Oriental Journal of Chemistry, 2020, 36(1): 189–194.

[25] Zhao L., Tian J., Li F., et al., Experimental and theoretical analysis of spray characteristics of biodiesel blends with diethyl carbonate in a common-rail injection system. Journal of Energy Engineering, 2023, 149(1): 05022003.

[26] Zhao T., Lyu D., Duan Y., et al., Spray characteristics of RP-3 jet fuel at non-evaporating and evaporating environments. Journal of Thermal Science, 2023, 32(1): 438–447.

[27] Zhang C., Guan Y., Huang Z., et al., Evaluation of auto-ignition characteristics of diesel surrogate fuels with the same derived cetane numbers at changed thermodynamic environments. Journal of Thermal Science, 2024, 33(4): 1590–1606.

[28] Han D., Zhai J., Huang Z., Autoignition of n-hexane, cyclohexane, and methylcyclohexane in a constant volume combustion chamber. Energy & Fuels, 2019, 33(4): 3576–3583.

[29] Ren Z., Wang L., Zhen H., et al., Spray auto-ignition behaviors of diesel and jet fuel at reduced oxygen environments. Combustion Science and Technology, 2022, 194(3): 574–588.

[30] Guan Y., Liu W., Han D., Comparative study on spray auto-ignition of DI-n-Butyl ether and diesel blends at engine-like conditions. Journal of Energy Resources Technology, 2021, 143(4): 042302.

[31] Huo J., Guan Y., Zhang M., et al., Diesel spray auto-ignition in different oxidizing atmospheres. Fuel, 2022, 328: 125308.

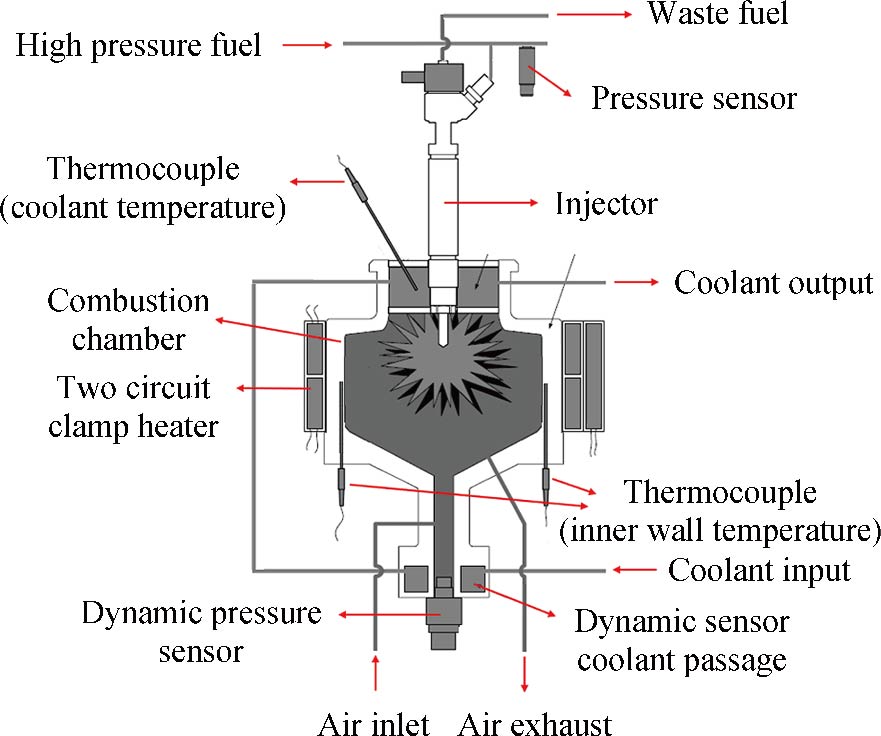

[32] ASTM, Standard test method for determination of derived cetane number (DCN) of diesel fuel oils—Ignition delay and combustion delay using a constant volume combustion chamber method. ASTM D7668-23, 2023.

[33] Liang X., Zhong A., Sun Z., et al., Autoignition of n-heptane and butanol isomers blends in a constant volume combustion chamber. Fuel, 2019, 254: 115638.

[34] Woschni G., A universally applicable equation for the instantaneous heat transfer coefficient in the internal combustion engine. 1967, SAE Technical Paper: 670931.

[35] Ong J.C., Walther J.H., Xu S., et al., Effects of ambient pressure and nozzle diameter on ignition characteristics in diesel spray combustion. Fuel, 2021, 290: 119887.

[36] Li G., Zhou M., Zhang Z., et al., Experimental and kinetic studies of the effect of CO2 dilution on laminar premixed n-heptane/air flames. Fuel, 2018, 227: 355–366.