[1] National Energy Administration of China, National energy administration releases national power industry statistics for 2022.

https://www.nea.gov.cn/2023-01/18/c_1310691509.htm, 2023 (accessed on December 20, 2023). (in Chinese)

[2] Gonzalez-Salazar M.A., Kirsten T., Prchlik L., Review of the operational flexibility and emissions of gas- and coal-fired power plants in a future with growing renewables. Renewable and Sustainable Energy Reviews, 2018, 82(1): 1497–1513.

[3] Du B., Liu P., Li Z., Coal power plants transition based on joint planning of power and central heating sectors: A case study of China. Energy, 2023, 283: 129108.

[4] Jin H., Guo J., Tang L., et al., Long-term electricity demand forecasting under low-carbon energy transition: Based on the bidirectional feedback between power demand and generation mix. Energy, 2024, 286: 129435.

[5] National Development and Reform Commission of China and National Energy Administration of China, Notice of the national development and reform commission and the national energy administration on the national reform and upgrading of the coal power generating units.

https://www.gov.cn/zhengce/zhengceku/2021-11/03/content_5648562.htm, 2021 (accessed on December 20, 2023). (in Chinese)

[6] Chen J., Xu W., Zuo H., et al., System development and environmental performance analysis of a solar-driven supercritical water gasification pilot plant for hydrogen production using life cycle assessment approach. Energy Conversion and Management, 2019, 184: 60–73.

[7] Zhao M., Wang Y., Wang X., et al., Flexibility evaluation of wind-PV-hydro multi-energy complementary base considering the compensation ability of cascade hydropower stations. Applied Energy, 2022, 315: 119024.

[8] Chen J., Xu W., Zhang F., et al., Thermodynamic and environmental analysis of integrated supercritical water gasification of coal for power and hydrogen production. Energy Conversion and Management, 2019, 198: 111927.

[9] Xie M., Cheng X., Cai H., et al., A hydropower scheduling model to analyze the impacts from integrated wind and solar powers. Sustainable Energy, Grids and Networks, 2021, 27: 100499.

[10] Chen J., Xu W., Wu X., et al., System development and environmental performance analysis of a pilot scale microbial electrolysis cell for hydrogen production using urban wastewater. Energy Conversion and Management, 2019, 193: 52–63.

[11] Liu Z., Cui Y., Wang J., et al., Multi-objective optimization of multi-energy complementary integrated energy systems considering load prediction and renewable energy production uncertainties. Energy, 2022, 254: 124399.

[12] Gan W., Yan M., Wen J., et al., A low-carbon planning method for joint regional-district multi-energy systems: From the perspective of privacy protection. Applied Energy, 2022, 311: 118595.

[13] Fu X., Guo Q., Sun H., Statistical machine learning model for stochastic optimal planning of distribution networks considering a dynamic correlation and dimension reduction. IEEE Transactions on Smart Grid, 2020, 11(4): 2904–2917.

[14] Fu X., Zhang C., Xu Y., et al., Statistical machine learning for power flow analysis considering the influence of weather factors on photovoltaic power generation. IEEE Transactions on Neural Networks and Learning Systems, 2025, 36(3): 5348–5362.

[15] Ye L., Lin H.X., Tukker A., Future scenarios of variable renewable energies and flexibility requirements for thermal power plants in China. Energy, 2019, 167: 708–714.

[16] Meng Y., Cao Y., Li J., et al., The real cost of deep peak shaving for renewable energy accommodation in coal-fired power plants: Calculation framework and case study in China. Journal of Cleaner Production, 2022, 367: 132913.

[17] Wang W., Li Z., Lyu J., et al., An overview of the development history and technical progress of China’s coal-fired power industry. Frontiers in Energy, 2019, 13: 417–426.

[18] Zhu S., Hui J., Lyu Q., et al., Experimental study on pulverized coal swirl-opposed combustion preheated by a circulating fluidized bed. Part A. Wide-load operation and low-NOx emission characteristics. Energy, 2023, 284: 128573.

[19] Hui J., Zhu S., Zhang X., et al., Experimental study of deep and flexible load adjustment on pulverized coal combustion preheated by a circulating fluidized bed. Journal of Cleaner Production, 2023, 418: 138040.

[20] Hossain M.N., Ghosh K., Effect of peripheral nonuniform distribution of furnace heat flux on thermo-hydraulic characteristics and design of riser downcomer circuit of natural circulation boiler. Applied Thermal Engineering, 2023, 224: 120135.

[21] Ferrand T., Oettig J., Schäfer L., et al., A limitation to determine heat transfer of water at supercritical pressure: The repeatability issue. Applied Thermal Engineering, 2023, 219: 119357.

[22] Wang P., Si F., Cao Y., et al., Prediction of superheated steam temperature for thermal power plants using a novel integrated method based on the hybrid model and attention mechanism. Applied Thermal Engineering, 2022, 203: 117899.

[23] Gan Y., Huang C., Wang W., Flow behavior of laval nozzle sets in steam turbine governing stage at low loads. Thermal Science and Engineering Progress, 2023, 46: 102209.

[24] Gu Y., Xu J., Chen D., et al., Overall review of peak shaving for coal-fired power units in China. Renewable and Sustainable Energy Reviews, 2016, 54: 723–731.

[25] Gao W., Liu M., Yin J., et al., An improved control strategy for a denitrification system using cooperative control of NH3 injection and flue gas temperature for coal-fired power plants. Energy, 2023, 282: 128759.

[26] Pang Y., Chi Y., Tian B., Economic evaluation of flexible transformation in coal-fired power plants with multi price links. Journal of Cleaner Production, 2023, 402: 136851.

[27] Zhang C., Wang Z., Comprehensive energy efficiency analysis of ultra-supercritical thermal power units. Applied Thermal Engineering, 2023, 235: 121365.

[28] Zhao Y., Xu P., Ju W., et al., Overview of theoretical and technical research on flexible and efficient synergistic operation of coal-fired power units during transient processes. Proceedings of the CSEE, 2023, 43: 2080–2098.

[29] Wei H., Lu Y., Yang Y., et al., Flexible operation mode of coal-fired power unit coupling with heat storage of extracted reheat steam. Journal of Thermal Science, 2022, 31: 436–447.

[30] Khaleel O.J., Ismail F.B., Ibrahim T.K., et al., Energy and exergy analysis of the steam power plants: A comprehensive review on the classification, development, improvements, and configurations. Ain Shams Engineering Journal, 2022, 13: 101640.

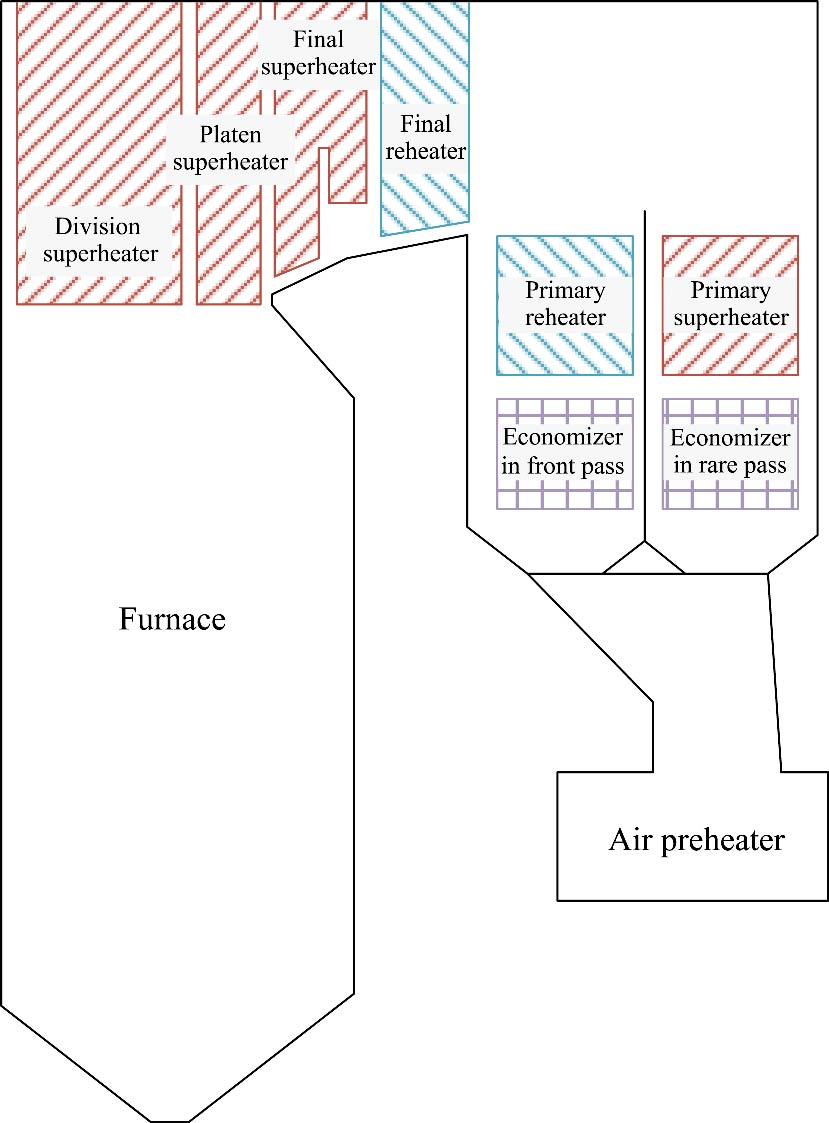

[31] Fan H., Xu W., Zhang J., et al., Steam temperature regulation characteristics in a flexible ultra-supercritical boiler with a double reheat cycle based on a cell model. Energy, 2021, 229: 120701.

[32] Ma T., Li Z., Lv K., et al., Design and performance analysis of deep peak shaving scheme for thermal power units based on high-temperature molten salt heat storage system. Energy, 2024, 288: 129557.

[33] Wang Z., Gu Y., Zhao Z., et al., Operational optimization on large-scale combined heat and power units with low-pressure cylinder near-zero output. Energy Science & Engineering, 2023, 11: 2081–2095.

[34] Hou G., Huang T., Zheng F., et al., A hierarchical reinforcement learning GPC for flexible operation of ultra-supercritical unit considering economy. Energy, 2024, 289: 129936.

[35] Xue Y., Sha W., Cai C., et al., Influence of main steam parameters on coal consumption rates: Calculation model comparison. Thermal Power Generation, 2015, 44: 76–80.

[36] Cui C., Zhao Y., Yan C., Parameter optimization design of regenerative extraction steam at parameter rising of subcritical unit. Journal of Engineering for Thermal Energy and Power, 2017, 32: 115–118.

[37] Wei H., Lu Y., Yang Y., et al., Research on influence of steam extraction parameters and operation load on operational flexibility of coal-fired power plant. Applied Thermal Engineering, 2021, 195: 11726.

[38] Wang C., Liu Z., Fan M., et al., Enhancing the flexibility and efficiency of a double-reheat coal-fired power unit by optimizing the steam temperature control: From simulation to application. Applied Thermal Engineering, 2022, 217: 119240.

[39] Zheng T., Thermal power plant, Second ed., China Electric Power Press, Beijing, 2008.

[40] Xia J., Chen G., Tan P., et al., An online case-based reasoning system for coal blends combustion optimization of thermal power plant. International Journal of Electrical Power & Energy Systems, 2014, 62: 299–311.

[41] Technical code for the design of auxiliary power system of fossil-fired power plant. Standards of Power Industry of the People’s Republic of China, Beijing, China, 2014.

[42] Ming X., Wang Q., Luo K., et al., An integrated economic, energy, and environmental analysis to optimize evaluation of carbon reduction strategies at the regional level: A case study in Zhejiang, China. Journal of Environmental Management, 2024, 351: 119742.

[43] Alobaid F., Mertens N., Starkloff R., et al., Progress in dynamic simulation of thermal power plants. Progress in Energy and Combustion Science, 2017, 59: 79–162.

[44] Oko E., Wang M., Dynamic modelling, validation and analysis of coal-fired subcritical power plant. Fuel, 2014, 135: 292–300.

[45] Feng J., Shen Y., Yang R., Boiler mechanics and calculations, Third ed, China Science Publishing & Media Ltd., Beijing, 2003.

[46] Wan L., Yang D., Zhou X., et al., Thermal-hydraulic calculation and analysis on evaporator system of a 1000 MW ultra-supercritical pulverized combustion boiler with double reheat. Journal of Thermal Science, 2020, 30: 807–816.

[47] Hossain M.N., Ghosh K., Manna N.K., et al., Integrated thermal modeling, analysis, and sequential design of heat exchanger surfaces of a natural circulation RDF boiler including evaporator tubes. Applied Thermal Engineering, 2022, 211: 118455.

[48] Han Z., Li P., Impacts of adding low-temperature economizer on condenser vacuum and thermal economic. Chemical Industry and Engineering Progress, 2015, 34: 54–54.

[49] Li X., Wang N., Wang L., et al., Identification of optimal operating strategy of direct air-cooling condenser for Rankine cycle based power plants. Applied Energy, 2018, 209: 153–166.

[50] Kuprianov V.I., Applications of a cost-based method of excess air optimization for the improvement of thermal efficiency and environmental performance of steam boilers. Renewable and Sustainable Energy Reviews, 2005, 9: 474–498.