[1]

Zeng S., Su B., Zhang M., et al., Analysis and forecast of China’s energy consumption structure. Energy Policy, 2021, 159: 112630.

[2]

Rao C., Zhang Y., Wen J., et al., Energy demand forecasting in China: A support vector regression-compositional data second exponential smoothing model. Energy, 2023, 263: 125995.

[3]

Shi M., Huang Y., Xu X., et al., China’s coal consumption forecasting using adaptive differential evolution algorithm and support vector machine. Resources Policy, 2021, 74: 102287.

[4]

Shi Q., Li C., Wang S., et al., Effect of the depositional environment on the formation of tar-rich coal: A case study in the northeastern Ordos Basin, China. Journal of Petroleum Science and Engineering, 2022, 216: 110828.

[5]

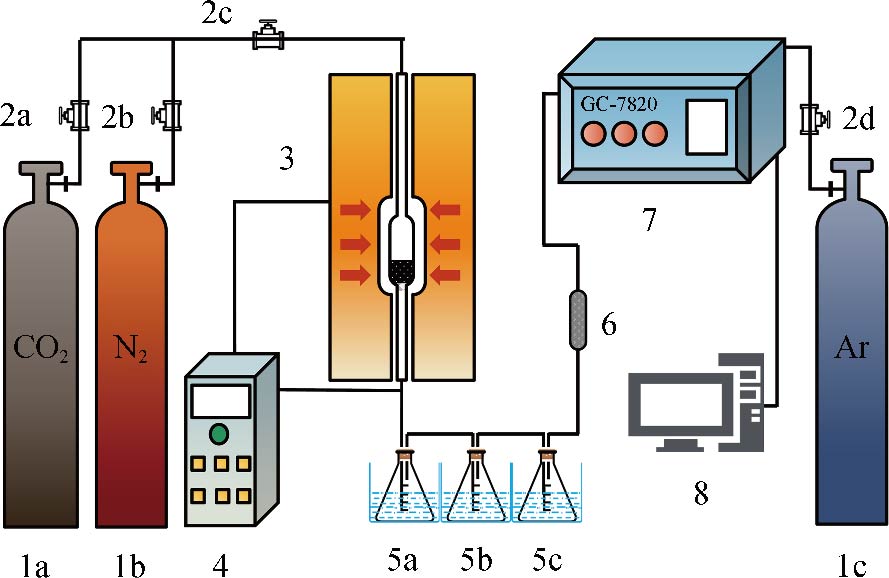

Chang Z., Wang C., Kuang W., et al., Product characterization and pore structure evolution of a tar-rich coal following pyrolysis under nitrogen, steam/nitrogen, and oxygen/nitrogen atmospheres. Journal of Analytical and Applied Pyrolysis, 2024, 180: 106563.

[6]

Ju Y., Zhu Y., Zhang Y., et al., Effects of high-power microwave irradiation on tar-rich coal for realising in situ pyrolysis, fragmentation, and low-carbon utilisation of tar-rich coal. International Journal of Rock Mechanics and Mining Sciences, 2022, 157: 105165.

[7]

Wang S., Shen Y., Song S., et al., Change of coal energy status and green and low-carbon development under the “dual carbon” goal. Journal of China Coal Society, 2023, 48(7): 2599–2612.

[8]

Ma L., Wang S., Duan Z., et al., Potential of oil-rich coal resources in Shaanxi Province and its new development suggestion. Coal Geology & Exploration, 2022, 50(2): 1–8.

[9]

Wang S., Shi Q., Wang S., et al., Resource property and exploitation concepts with green and low-carbon of tar-rich coal as coal-based oil and gas. Journal of China Coal Society, 2021, 46(5): 1365–1377.

[10]

Xue F., Li D., Guo Y., et al., Technical progress and the prospect of low-rank coal pyrolysis in China. Energy Technology, 2017, 5(11): 1897–1907.

[11]

Huang Z., Zhou W., et al., Study on the molecular structure model of tar-rich coal and its pyrolysis process. Journal of Molecular Structure, 2023, 1286: 135613.

[12]

Shi Q., Mi Y., Wang S., et al., Pyrolysis behavior of tar-rich coal with various coal-forming environments: A TGA and in-situ transmission FTIR study. Fuel, 2024, 358: 130250.

[13]

Yu Z., Guo W., Yang P., et al., In-situ infrared and kinetic characteristics analysis on pyrolysis of tar-rich coal and macerals. Fuel, 2023, 348: 128601.

[14]

Tang Y., Wu X., Li L., et al., Heating technology of in-situ pyrolysis for tar-rich coal and its high efficiency process. Clean Coal Technolgy, 2023, 29(12): 42–50.

[15]

Nguyen M., Berndt C., Reichel D., et al., Pyrolysis behaviour study of a tar- and sulphur-rich brown coal and GC-FID/MS analysis of its tar. Journal of Analytical and Applied Pyrolysis, 2015, 115: 194–202.

[16]

Sun S., Xu D., Wei Y., et al., Influence laws of operating parameters on coal pyrolysis characteristics. Journal of Analytical and Applied Pyrolysis, 2022, 167: 105684.

[17]

Zhang J., Shi R., Niu B., et al., Effect of CH

4 atmosphere on tar yield and quality in coal pyrolysis at lowmedium pyrolysis temperature. Journal of China Coal Society, 2021, 46(1): 292–299.

[18]

Chang Q., Gao R., Li H., et al., Effects of CO

2 on coal rapid pyrolysis behavior and chemical structure evolution. Journal of Analytical and Applied Pyrolysis, 2017, 128: 370–378.

[19]

Niu B., Liu R., Zhang J., et al., Effect of O

2/CH

4 atmosphere on tar production during coal pyrolysis. Journal of Analytical and Applied Pyrolysis, 2021, 159: 105317.

[20]

Niu S., Zhou Y., Zhang W., et al., Research progress of the influence of atmosphere on coal pyrolysis behavior. Applied Chemical Industry, 2019, 48(03): 639–645.

[21]

Duan L., Zhao C., Zhou W., et al., Investigation on coal pyrolysis in CO

2 atmosphere. Energy & Fuels, 2009, 23(7): 3826–3830.

[22]

Luo Y., Ben H., Wu Z., et al., Impact of CO

2 on pyrolysis products of bituminous coal and platanus sawdust. Polymers, 2019, 11(8): 1370–1370.

[23]

Niu S., Zhou Y., Zhu S., et al., Investigation into the yields and characteristics of products from lignite low-temperature pyrolysis under CO

2 and N

2 atmospheres. Journal of Analytical and Applied Pyrolysis, 2019, 138: 161–169.

[24]

Kim Y., Lee J., Yi H., et al., Investigation into role of CO

2 in two-stage pyrolysis of spent coffee grounds. Bioresour Technolgy, 2019, 272: 48–53.

[25]

Kwon D., Lee S.S., Jung S., et al., CO

2 to fuel via pyrolysis of banana peel. Chemical Engineering Journal, 2020, 392: 123774.

[26]

Ordonez-Loza J., Valdes C., Chejne F., et al., Effect of carbon dioxide environment on the thermal behavior of sugarcane pyrolysis oil. Journal of Analytical and Applied Pyrolysis, 2021, 154: 105000.

[27]

Kwon E.E., Jeon E.C., Castaldi M.J., et al., Effect of carbon dioxide on the thermal degradation of lignocellulosic biomass. Environmental Science Technolgy, 2013, 47(18): 10541–10547.

[28]

Yang M., Luo B., Shao J., et al., The influence of CO

2 on biomass fast pyrolysis at medium temperatures. Journal of Renewable and Sustainable Energy, 2018, 10(1): 013108.

[29]

Yi Z, Li C, Zhang L., Impacts of CO

2 atmosphere on property of the biochar from pyrolysis of lignin. Journal of Analytical and Applied Pyrolysis, 2022, 167: 105689.

[30]

Wu Y, Tao S, Wang Z., Effect of pyrolysis atmospheres on gaseous products evolution of coal pyrolysis at high temperature. Fuel, 2024, 366: 131336.

[31]

Liu Q., Wen Y., Zhong M., et al., Insight into pyrolysis behaviors of cedar under different atmospheres via a fixed-bed reactor. Fuel, 2024, 368: 131607.

[32]

Wang Z., Wei B., Lü J., In-situ catalytic upgrading of tar from integrated process of coal pyrolysis with steam reforming of methane over carbon based Ni catalyst. Journal of Fuel Chemistry and Technology, 2022, 50(2): 129–142.

[33]

Wei B., Jin L., Wang D., et al., Catalytic upgrading of lignite pyrolysis volatiles over modified HY zeolites. Fuel, 2020, 259: 116234.

[34]

Yue C., Gao P., Tang L., et al., Effects of N

2/CO

2 atmosphere on the pyrolysis characteristics for municipal solid waste pellets. Fuel, 2022, 315: 123233.

[35]

Song Q., Zhao H., Xing W., Effects of various additives on the pyrolysis characteristics of municipal solid waste. Waste Management, 2018, 78: 621–629.

[36]

Chan W., Yusoff S., Veksha A., Analytical assessment of tar generated during gasification of municipal solid waste: Distribution of GC-MS detectable tar compounds, undetectable tar residues and inorganic impurities. Fuel, 2020, 268: 117348.

[37]

Cho D.W., Kwon E.E., Kwon G., et al., Co-pyrolysis of paper mill sludge and spend coffee ground using CO

2 as reaction medium. Journal of CO

2 Utilization, 2017, 21: 572–579.

[38]

Lee S.R., Lee J , Lee T., et al. Strategic use of CO2 for co-pyrolysis of swine manure and coal for energy recovery and waste disposal. Journal of CO

2 Utilization, 2017, 22: 110–116.

[39]

Ismail T.M., Ramos A., Monteiro E., Parametric studies in the gasification agent and fluidization velocity during oxygen-enriched gasification of biomass in a pilot-scale fluidized bed: Experimental and numerical assessment. Renewable Energy, 2020, 147: 2429–2439.

[40]

He X., Liu X., Nie B., et al., FTIR and Raman spectroscopy characterization of functional groups in various rank coals. Fuel, 2017, 206: 555–563.

[41]

Li J., Zhu J., Hu H., et al., Co-pyrolysis of Baiyinhua lignite and pine in an infrared-heated fixed bed to improve tar yield. Fuel, 2020, 272: 117739.

[42]

Ma L., Yu W., Ren L., et al., Micro-characteristics of low-temperature coal oxidation in CO

2/O

2 and N

2/O

2 atmospheres. Fuel, 2019, 246: 259–267.

[43]

Luo K., Zhang C., Zhu S., et al., Tar formation during coal pyrolysis under N

2 and CO

2 atmospheres at elevated pressures. Journal of Analytical and Applied Pyrolysis, 2016, 118: 130–135.

[44]

Dong J., Li F., Xie K., Study on the source of polycyclic aromatic hydrocarbons (PAHs) during coal pyrolysis by PY-GC-MS. Journal of Hazardous Materials, 2012, 243: 80–85.

[45]

Xu B., Argyle M.D., Shi X., et al. Effects of mixture of CO

2/CH

4 as pyrolysis atmosphere on pine wood pyrolysis products. Renewable Energy, 2020, 162: 1243–1254.

[46]

Blazsó M., Jakab E., Study of thermal decomposition reactions in coals by pyrolysis-gas chromatography-mass spectrometry. Journal of Analytical and Applied Pyrolysis, 1985, 8: 189–194.

[47]

Pang Y., Mechanism and model of phenols formation during multistage rotary furnace pyrolysis. Fuel and Energy Abstracts, 1995, 01: 75‒81.

[48]

Siskin M., Aczel T., Pyrolysis studies on the structure of ethers and phenols in coal. Fuel, 1983, 62(11): 1321–1326.

[49]

Schlosberg R.H., Davis Jr W.H., Ashe T.R., Pyrolysis studies of organic oxygenates. 2. Benzyl phenyl ether pyrolysis under batch autoclave conditions. Fuel, 1981, 60(3): 201–204.

[50]

Zou D., Jin L., Zhong M., et al., Catalytic performance of modified kaolinite in pyrolysis of benzyl phenyl ether: A model compound of low rank coal. Journal of the Energy Institute, 2020, 93(6): 2314–2324.

[51]

Peterson C.A., Lindstrom J.K., Polin J.P., et al., Oxidation of phenolic compounds during autothermal pyrolysis of lignocellulose. Journal of Analytical and Applied Pyrolysis, 2020, 149: 104853.

[52]

Asmadi M., Kawamoto H., Saka S., Thermal reactivities of catechols/pyrogallols and cresols/xylenols as lignin pyrolysis intermediates. Journal of Analytical and Applied Pyrolysis, 2011, 92(1): 76–87.