[1]

Stocker T.F., Climate change 2013: The physical science basis: Working group I contribution to the fifth assessment report of the intergovernmental panel on climate change, first ed., Cambridge University Press (CUP), Cambridge, 2014.

[2]

Mengis N., Matthews H.D., Non-CO2 forcing changes will likely decrease the remaining carbon budget for 1.5°C. NPJ Climate and Atmospheric Science, 2020, 3(19): 1–7.

[3]

Price S.J., Sherlock R.R., Kelliher F.M., et al., Pristine New Zealand forest soil is a strong methane sink. Global Change Biology, 2010, 10(1): 16–26.

[4]

Zhang J., Wang Y.Y., Wang Y., et al., Solar driven gas phase advanced oxidation processes for methane removal —Challenges and perspectives. Chemistry: A European Journal, 2022, 28(64): e202201984.

[5]

Brenneis R.J., Johnson E.P., Shi W., et al., Atmospheric- and low-level methane abatement via an earth-abundant catalyst. ACS Environmental Au, 2022, 2(3): 223–231.

[6]

Chen X., Li Y., Pan X., et al., Photocatalytic oxidation of methane over silver decorated zinc oxide nanocatalysts. Nature Communications, 2016, 7: 12273.

[7]

Li Z., Pan X., Yi Z., Photocatalytic oxidation of methane over CuO-decorated ZnO nanocatalysts. Journal of Materials Chemistry A, 2019, 7(2): 469–475.

[8]

Ahmed K., Wang Y., Bai Y., et al., A carbon nanowire-promoted Cu2O/TiO2 nanocomposite for enhanced photoelectrochemical performance. New Journal of Chemistry, 2022, 46(32): 15495–15503.

[9]

Haaf W., Friedrich K., Mayr G., Schlaich J., Solar chimneys Part I: Principle and construction of the pilot plant in Manzanares. International Journal of Solar Energy, 1983, 2(1): 3–20.

[10]

Danook S.H., AL-bonsrulah H.A.Z., Hashim I., et al., CFD simulation of a 3D solar chimney integrated with an axial turbine for power generation. Energies, 2021, 14(18): 5771.

[11]

Ghalamchi M., Kasaeian A., Ghalamchi M., et al., An experimental study on the thermal performance of a solar chimney with different dimensional parameters. Renewable Energy, 2016, 91: 477–483.

[12]

Ghalamchi M., Kasaeian A., Ghalamchi M., Experimental study of geometrical and climate effects on the performance of a small solar chimney. Renewable and Sustainable Energy Reviews, 2015, 43: 425–431.

[13]

Kasaeian A., Ghalamchi M., Ghalamchi M., Simulation and optimization of geometric parameters of a solar chimney in Tehran. Energy Conversion and Management, 2014, 83: 28–34.

[14]

Zuo L., Ding L., Chen J., et al., Comprehensive study of wind supercharged solar chimney power plant combined with seawater desalination. Solar Energy, 2018, 166: 59–70.

[15]

Ferreira A.G., Maia C.B., Cortez M.F.B., et al., Technical feasibility assessment of a solar chimney for food drying. Solar Energy, 2008, 82(3): 198–205.

[16]

Bernardes M.A.D.S., Zhou X., On the heat storage in solar updraft tower collectors-water bags. Solar Energy, 2013, 91: 22–31.

[17]

Bouabidi A., Ayadi A., Nasraoui H., et al., Study of solar chimney in Tunisia: Effect of the chimney configurations on the local flow characteristics. Energy and Buildings, 2018, 169: 27–38.

[18]

Zuo L., Liu Z., Ding L., et al., Performance analysis of a wind supercharging solar chimney power plant combined with thermal plant for power and freshwater generation. Energy Conversion and Management, 2020, 204: 112282.

[19]

Maia C.B., Castro Silva J.d.O., Thermodynamic assessment of a small-scale solar chimney. Renewable Energy, 2022, 186: 35–50.

[20]

De Richter R., Ming T., Davies P., et al., Removal of non-CO2 greenhouse gases by large-scale atmospheric solar photocatalysis. Progress in Energy and Combustion Science, 2017, 60: 68–96.

[21]

Ming T.Z., Gui H.Y., Shi T.H., et al., Solar chimney power plant integrated with a photocatalytic reactor to remove atmospheric methane: A numerical analysis. Solar Energy, 2021, 226: 101–111.

[22]

Xiong H., Ming T., Wu Y., et al., Numerical analysis of a negative emission technology of methane to mitigate climate change. Solar Energy, 2023, 255: 416–424.

[23]

Ming T., Xiong H., Shi T., et al., A novel green technology: Reducing carbon dioxide and eliminating methane from the atmosphere. International Journal of Energy Research, 2022, 46: 20107–20120.

[24]

Yu B., Li N., He W., et al., Multifunctional solar wall for dehumidification, heating and removal of formaldehyde: Part 1. System description, preparation and performance of SiO2/TiO2 adsorbent. Building and Environment, 2016, 100: 203–214.

[25]

Yu B., He W., Li N., et al., Experiments and kinetics of solar PCO for indoor air purification in PCO/TW system. Building and Environment, 2017, 115: 130–146.

[26]

Wu S., Yan X., Xiao L., Numerical analysis on geometric and shape parameters of solar dual-catalytic Trombe wall performance. Solar Energy, 2020, 199: 460–473.

[27]

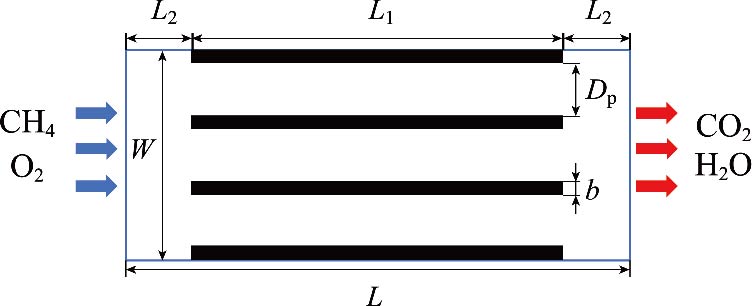

Li A., Ming T., Xiong H., et al., A high-performance solar chimney in building integrated with photocatalytic technology for atmospheric methane removal. Solar Energy, 2023, 260: 126–136.

[28]

Li J., Wang G., Zhang X., Molecular dynamics study on the mechanism of nanoparticle phase change caused by collision with wall surface. Journal of Thermal Science, 2022, 31: 1145–1154.

[29]

Wang Y., Xu J., Ma X., Interaction between neighboring supercritical water molecules and density fluctuation by molecular dynamics simulations. Journal of Thermal Science, 2022, 31: 907–922.

[30]

Huang X., Huai X., Molecular dynamics simulation of thermal conductivity in Si-Ge nanocomposites. Chinese Physics Letters, 2008, 25: 2973–2976.

[31]

Chen S., Doolen G.D., Lattice Boltzmann method for fluid flows. Annual Review of Fluid Mechanics, 1998, 30: 329–364.

[32]

He Y., Ren A., Tang T., et al., Multi-scale numerical simulation of flow, heat and mass transfer behaviors in dense gas-solid flows: A brief review. Journal of Thermal Science, 2022, 31(3): 607–633.

[33]

Kang Q., Lichtner P.C., A Lattice Boltzmann method for coupled fluid flow, solute transport, and chemical reaction. Progress in Computational Physics, 2013, 3: 184–198.

[34]

Xin F., Li X.F., Xu M., et al., Simulation of gas exothermic chemical reaction in porous media reactor with lattice Boltzmann method. Journal of Thermal Science, 2013, 22: 42–47.

[35]

Jun C., Huai X.L., A lattice Boltzmann model for fluid-solid coupling heat transfer in fractal porous media. Chinese Physics Letters, 2009, 26(6): 064401.

[36]

Cai J., Huai X., Study on fluid-solid coupling heat transfer in fractal porous medium by lattice Boltzmann method. Applied Thermal Engineering, 2010, 30(6): 715–723.

[37]

Chen L., Kang Q.J., He Y.L., et al., Pore-scale simulation of coupled multiple physicochemical thermal processes in micro reactor for hydrogen production using lattice Boltzmann method. International Journal of Hydrogen Energy, 2012, 37(19): 13943–13957.

[38]

Li X., Cai J., Xin F., et al., Lattice Boltzmann simulation of endothermal catalytic reaction in catalyst porous media. Applied Thermal Engineering, 2013, 50(1): 1194–1200.

[39]

Alfano O. M., Cassano A. E., Scaling-up of photoreactors: Applications to advanced oxidation processes. Advances in Chemical Engineering, 2009, 36: 229–287.

[40]

Meng X., Cui X., Rajan N.P., et al., Direct methane conversion under mild condition by thermo-, electro-, or photocatalysis. Chem, 2019, 5(9): 2296–2325.

[41]

Oppermann R.H., The mathematical theory of non-uniform gases. an account of the kinetic theory of viscosity, thermal conduction, and diffusion in gases. Journal of the Franklin Institute, 1970, 231: 198–199.

[42]

Chen L., Zhang R., Min T., et al., Pore-scale study of effects of macroscopic pores and their distributions on reactive transport in hierarchical porous media. Chemical Engineering Journal, 2018, 349: 428–437.

[43]

Haeger A., Kleinschmidt O., Hesse D., Kinetics of photocatalyzed gas reactions using titanium dioxide as the catalyst. Part II: Photocatalyzed total oxidation of alkanes with oxygen. Chemical Engineering and Technology, 2005, 27(9): 1019–1026.

[44]

Huai X., Koyama S., An experimental study of carbon dioxide condensation in mini channels. Journal of Thermal Science, 2004, 13: 358–365.

[45]

Wang T., Gao Z., Bai J., et al., Thermal performance of mini cooling channels for high-power servo motor with non-uniform heat dissipation. Journal of Thermal Science, 2023, 32: 650–661.

[46]

Mehdi S., Mehdi M., Masaud M., Modeling of heat transfer at the fluid-solid interface by lattice Boltzmann method. International Journal of Thermal Sciences, 2014, 75: 28–35.

[47]

Pirouz M.M., Farhadi M., Sedighi K., et al., Lattice Boltzmann simulation of conjugate heat transfer in a rectangular channel with wall-mounted obstacles. Scientia Iranica, 2011, 18(2): 213–221.

[48]

Xiong H., Ming T., Wu Y., et al., Numerical analysis of solar chimney power plant integrated with CH4 photocatalytic reactors for fighting global warming under ambient crosswind. Renewable Energy, 2022, 201(1): 678–690.

[49]

Guo B., Xu H.J., Zhao C.Y., Lattice Boltzmann modelling on pore-scale reactive transport in exothermic reactions of solid blocks for thermochemical energy storage. Applied Thermal Engineering, 2022, 216: 119145.

[50]

Li X., Chen J., Xu M., et al., Lattice Boltzmann simulation of catalytic reaction in porous media with buoyancy. Applied Thermal Engineering, 2014, 70(1): 586–592.

[51]

Haeger A., Kleinschmidt O., Hesse D., Kinetics of photocatalyzed gas reactions using titanium dioxide as the catalyst, Part II: Photocatalyzed total oxidation of alkanes with oxygen. Chemical Engineering & Technology, 2004, 27(9): 1019–1026.

[52]

Chen X., Li Y., Pan X., et al., Photocatalytic oxidation of methane over silver decorated zinc oxide nanocatalysts. Nature Communications, 2016, 7: 12273.

[53]

Li A., Ming T., Xiong H., et al., A high-performance solar chimney in building integrated with photocatalytic technology for atmospheric methane removal. Solar Energy, 2023, 260: 126–136.