[1]

Eastman J.A., Choi U.S., Li S., et al., Enhanced thermal conductivity through the development of nanofluids. MRS Online Proceedings Library, 1996, 457: 3–11.

[2]

Ghanbarpour M., Haghigi E.B., Khodabandeh R., Thermal properties and rheological behaviour of water based Al2O3 nanofluid as a heat transfer fluid. Experimental Thermal and Fluid Science, 2014, 53: 227–235.

[3]

Mintsa H.A., Roy G., Nguyen C.T., et al., New temperature dependent thermal conductivity data for water-based nanofluids. International Journal of Thermal Sciences, 2009, 48(2): 363–371.

[4]

Duan F., Thermal property measurement of Al2O3-water nanofluids. Hashim A. ed., InTech Europe, Croatia, 2012, pp: 335–357.

[5]

Das S.K., Putra N., Thiesen P., et al., Temperature dependence of thermal conductivity enhancement for nanofluids. Journal of Heat Transfer, 2003, 125(4): 567–574.

[6]

Issa R.J., Effect of nanoparticles size and concentration on thermal and rheological properties of Al2O3-water nanofluids. International Conference on Experimental and Numerical Flow and Heat Transfer (ENFHT’16), Prague, Czech Republic, 2016.

[7]

Chandrasekar M., Suresh S., Chandra B.A., Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluid. Experimental Thermal and Fluid Science, 2010, 34(2): 210–216.

[8]

Issa R.J., A review on thermophysical properties and Nusselt number behavior of Al2O3 nanofluids in heat exchangers. Journal of Thermal Science, 2021, 30(2): 418–431.

[9]

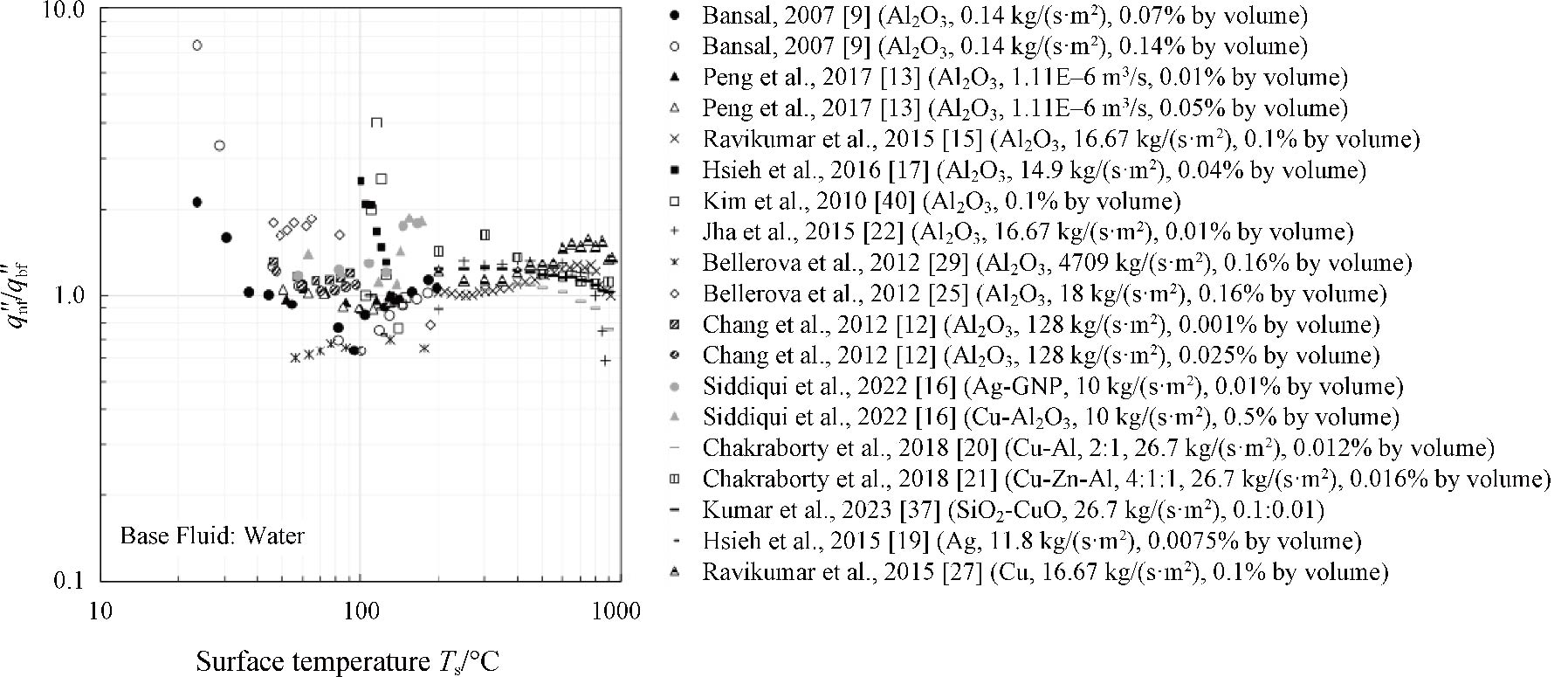

Bansal A., Alumina nanofluid for spray cooling heat transfer enhancement. University of South Florida, M.S. Thesis, 2007.

[10]

Okawa T., Nagano K., Hirano T., Boiling heat transfer during single nanofluid drop impacts onto a hot wall. Experimental Thermal and Fluid Science, 2012, 36: 78–85.

[11]

Chakraborty S., Sengupta I., Sarkar I., et al., Effect of surfactant on thermo-physical properties and spray cooling heat transfer performance of Cu-Zn-Al LDH nanofluid. Applied Clay Science, 2019, 168: 43–55.

[12]

Chang T.B., Syu S.C., Yang Y.K., Effects of particle volume fraction on spray heat transfer performance of Al2O3-water nanofluid. International Journal of Heat and Mass Transfer, 2012, 55: 1014–1021.

[13]

Peng Y.H., Cheng W.L., Experimental investigation on the effect of heat transfer enhancement of vacuum spray flash evaporation cooling using Al2O3-water nanofluid. Energy Procedia, 2017, 142: 3766–3773.

[14]

Duursma G., Sefiane K., Kennedy A., Experimental studies of nanofluid droplets in spray cooling. Heat Transfer Engineering, 2009, 30(13): 1108–1120.

[15]

Ravikumar S.V., Haldar K., Jha J.M., et al., Heat transfer enhancement using air-atomized spray cooling with water-Al2O3 nanofluid. International Journal of Thermal Sciences, 2015, 96: 85–93.

[16]

Siddiqui F.R., Tso C.Y., Qiu H., et al., Hybrid nanofluid spray cooling performance and its residue surface effects: Toward thermal management of high heat flux devices. Applied Thermal Engineering, 2022, 211: 1–13.

[17]

Hsieh S.S., Liu H.H., Yeh Y.F., Nanofluids spray heat transfer enhancement. International Journal of Heat and Mass Transfer, 2016, 94: 104–118.

[18]

Bellerova H., Pohanka M., Spray cooling by multi-walled carbon nanotubes and Fe nanoparticles. Transactions on Modelling and Simulation, 2011, 51: 293–304.

[19]

Hsieh S.S., Leu H.Y., Liu H.H., Spray cooling characteristics of nanofluids for electronic power devices. Nanoscale Research Letters, 2015, 10(139): 1–16.

[20]

Chakraborty S., Sarkar I., Ashok A., et al., Synthesis of Cu-Al LDH nanofluid and its application in spray cooling heat transfer of a hot steel plate. Powder Technology, 2018, 335: 285–300.

[21]

Chakraborty S., Sarkar I., Ashok A., et al., Thermo- physical properties of Cu-Zn-Al LDH nanofluid and its application in spray cooling. Applied Thermal Engineering, 2018, 141: 339–351.

[22]

Jha J.M., Ravikumar S.V., Tiara A.M., et al., Ultrafast cooling of a hot moving steel plate by using alumina nanofluid based air atomized spray impingement. Applied Thermal Engineering, 2015, 75: 738–747.

[23]

Modak M., Chougule S.S., Sahu S.K., An experimental investigation on heat transfer characteristics of hot surface by using CuO-water nanofluids in circular jet impingement cooling. Journal of Heat Transfer, 2018, 140: 1–10.

[24]

Tiara A.M., Chakraborty S., Sarkar I., et al., Effect of alumina nanofluid jet on the enhancement of heat transfer from a steel plate. Heat and Mass Transfer, 2017, 53: 2187–2197.

[25]

Bellerova H., Tseng A.A., Pohanka M., et al., Heat transfer of spray cooling using alumina/water nanofluids with full cone nozzles. Heat and Mass Transfer, 2012, 48(11): 1971–1983.

[26]

Pattanayak B., Mund A., Jayakumar J.S., et al., Spray impingement heat transfer using nanofluid – Experimental study. Advances in Fluid and Thermal Engineering, 2019, pp: 369–377.

[27]

Ravikumar S.V., Jha J.M., Haldar K., et al., Surfactant-based Cu-water nanofluid spray for heat transfer enhancement of high temperature steel surface. Journal of Heat Transfer, 2015, 137: 1–8.

[28]

Mitra S., Saha S.K., Chakraborty S., et al., Study on boiling heat transfer of water-TiO2 and water-MWCNT nanofluids based laminar jet impingement on heated steel surface. Applied Thermal Engineering, 2012, 37: 353–359.

[29]

Bellerova H., Tseng A.A., Pohanka M., et al., Spray cooling by solid jet nozzles using alumina/water nanofluids. International Journal of Thermal Sciences, 2012, 62: 127–137.

[30]

Padiyaar R., Krishnan S.J., Mahdavi M., et al., Experimental and numerical investigation to evaluate the thermal performance of jet impingement surface cooling with MWCNT/Al2O3-deionized water hybrid nanofluid. International Journal of Thermal Sciences, 2023, 184: 1–18.

[31]

Chang T.B., Formation of nano-adsorption layer and its effects on nanofluid spray heat transfer performance. Journal of Heat Transfer, 2015, 137: 1–11.

[32]

Kang B., Marengo M., Begg S., A study of the effect of nanoparticle concentration on the characteristics of nanofluid sprays. Journal of Applied Fluid Mechanics, 2019, 12: 413–420.

[33]

Wang B.X., Liu Z.X., Zhang B., et al., Effect of nanoparticle type and surfactant on heat transfer enhancement in spray cooling. Journal of Thermal Science, 2020, 29(3): 708–717.

[34]

Tseng A.A., Bellerova H., Pohanka M., et al., Effects of titania nanoparticles on heat transfer performance of spray cooling with full cone nozzle. Applied Thermal Engineering, 2014, 62: 20–27.

[35]

Bao J., Wang Y., Kosonen R., et al., Investigation on spray cooling heat transfer performance with different nanoparticles and surfactants. Heat and Mass Transfer, 2022, 58: 887–901.

[36]

Marseglia G., Sanches M., Ribeiro A.P.C., et al., Thermofluid characterization of nanofluids in spray cooling. Applied Thermal Engineering, 2022, 210: 1–17.

[37]

Kumar P., Chaurasia C.K., Das S., et al., Synthesis, characterization and application of SiO2 and CuO nanofluid in spray cooling of hot steel plate. Heat and Mass Transfer, 2023, 59(8): 1409–1436.

[38]

Maly M., Moita A.S., Jedelsky J., et al., Effect of nanoparticles concentration on the characteristics of nanofluid sprays for cooling applications. Journal of Thermal Analysis and Calorimetry, 2019, 135: 3375–3386.

[39]

Lee D.H., Irmawati N., Investigation on fluid flow and heat transfer characteristics in spray cooling systems using nanofluids. International Journal of Aerospace and Mechanical Engineering, 2015, 9(8): 1–5.

[40]

Kim H., Ahn H.S., Kim M.H., On the mechanism of pool boiling critical heat flux enhancement in nanofluids. Journal of Heat Transfer, 2010, 132(6): 061501.

[41]

Issa R., Numerical modelling of the dynamics and heat transfer of impacting sprays for a wide range of pressures. Doctoral Dissertation, University of Pittsburgh, 2003.

[42]

Liu Z., Li S., Pan X., et al., Mechanism study on spreading dynamics of nanofluids droplet coupled with thermal evaporation. International Journal of Heat and Mass Transfer, 2022, 183: 1–13.

[43]

Aksoy Y.T., Castanet G., Eneren P., et al., Experimental investigation of the influence of nanoparticles on droplet spreading dynamics and heat transfer during early stage cooling. Experimental Thermal and Fluid Science, 2023, 149: 1–9.

[44]

Pournaderi P., Deilami M., Modeling nanofluid droplet impingement on a superheated surface. Powder Technology, 2021, 381: 68–81.

[45]

Shen J., Liburdy J.A., Pence D.V., et al., Droplet impingement dynamics: effect of surface temperature during boiling and non-boiling conditions. Journal of Physics: Condensed Matter, 2009, 21: 1–14.

[46]

Torres J., Boiling and spreading behavior of impinging nanofluid droplets on a heated surface. M.S. Thesis, Rutgers, the State University of New Jersey, 2011.

[47]

Incropera F.P., Dewitt D.P., Bergman T.L., et al., Fundamentals of heat and mass transfer, 8th ed., John Wiley & Sons, 2018.