[1]

Ramkumar M.S., Reddy C.S.R., Ramakrishnan A., et al., Review on Li-ion battery with battery management system in electrical vehicle. Advances in Materials Science and Engineering, 2022, 1: 3379574.

[2]

Zhou L., He L., Zheng Y., et al., Massive battery pack data compression and reconstruction using a frequency division model in battery management systems. Journal of Energy Storage, 2020, 28: 101252.

[3]

Ma S., Jiang M., Tao P., et al., Temperature effect and thermal impact in lithium-ion batteries: A review. Progress in Natural Science: Materials International, 2018, 28(6): 653–666.

[4]

Zhao X., Zou D., Wang S., Flexible phase change materials: preparation, properties and application. Chemical Engineering Journal, 2022, 431: 134231.

[5]

Cui Y., Cong B., Liu J., et al., Characteristics and hazards of plug-in hybrid electric vehicle fires caused by lithium-ion battery packs with thermal runaway. Frontiers in Energy Research, 2022, 10: 878035.

[6]

Padhi U.P., Oh J., Mehrotra A., et al., A predictive theory on thermal runaway of ultrahigh capacity lithium-ion batteries. Combustion and Flame, 2023, 258: 113116.

[7]

Zhang L., Chen Y., Ge H., et al., Radiation-induced thermal runaway propagation in a cylindrical Li-ion battery pack: non-monotonicity, chemical kinetics, and geometric considerations. Applied Sciences, 2023, 13(14): 8229.

[8]

Wang J., Qin D., Wang T., Study on heat dissipation structure of air-cooled lithium ion battery module. Journal of Physics: Conference Series, 2022, 2174(1): 12035.

[9]

Zare P., Perera N., Lahr J., et al., A novel thermal management system for cylindrical lithium-ion batteries using internal-external fin-enhanced phase change material. Applied Thermal Engineering, 2024, 238: 121985.

[10]

Chen M., Yu Y., Ouyang D., et al., Research progress of enhancing battery safety with phase change materials. Renewable and Sustainable Energy Reviews, 2024, 189: 113921.

[11]

Melendez I., Morgan K., Troxler C., et al., Vat photopolymerization for thermal energy storage applications using encapsulated phase change material suspended in photocurable resin. Thermal Science and Engineering Progress, 2024, 56: 102986.

[12]

Ni R., Zhang D., Wang R., et al., Prevention and suppression effects of phase change material on thermal runaway in batteries. Case Studies in Thermal Engineering, 2023, 48: 103160.

[13]

Wang Y., Bailey J., Zhu Y., et al., Application of carbon nanotube prepared from waste plastic to phase change materials: the potential for battery thermal management. Waste Management, 2022, 154: 96–104.

[14]

Liu C., Xiao T., Zhao J., et al., Polymer engineering in phase change thermal storage materials. Renewable and Sustainable Energy Reviews, 2023, 188: 113814.

[15]

Freeman T.B., Foster K.E.O., Troxler C.J., et al., Advanced materials and additive manufacturing for phase change thermal energy storage and management: A review. Advanced Energy Materials, 2023, 13(24): 2204208.

[16]

Lv L., Ai H., Chen T., et al., A green, robust, and versatile BN nanosheet unidirectional aerogel encapsulated phase change material for effective thermal management of electronics and solar-thermoelectric conversion. Journal of Materials Chemistry A, 2023, 11(13): 7115–7127.

[17]

Zhang P., Qiu Y., Ye C., et al., Anisotropically conductive phase change composites enabled by aligned continuous carbon fibers for full-spectrum solar thermal energy harvesting. Chemical Engineering Journal, 2023, 461: 141940.

[18]

Yang X., Li C., Ma Y., et al., High thermal conductivity of porous graphite/paraffin composite phase change material with 3D porous graphite foam. Chemical Engineering Journal, 2023, 473: 145364.

[19]

Hu X., Huang X., Quan B., et al., Tree-inspired and scalable high thermal conductivity ethylene-vinyl acetate copolymer/expanded graphite/paraffin wax phase change composites for efficient thermal management. Chemical Engineering Journal, 2023, 471: 144720.

[20]

Cheng S., Guo X., Tan P., et al., A graphene aerogel with reversibly tunable thermal resistance for battery thermal management. Journal of Materials Chemistry A, 2023, 11(33): 17779–17786.

[21]

Cheng J., Niu S., Zhao Y., et al., The flame retardant and thermal conductivity properties of high thermal conductivity expandable graphite microcapsule filled natural rubber composites. Construction and Building Materials, 2022, 318: 125998.

[22]

Tarannum F., Danayat S., Nayal A., et al., Thermally expanded graphite polyetherimide composite with superior electrical and thermal conductivity. Materials Chemistry and Physics, 2023, 298: 127404.

[23]

Blackley E., Lai T., Odukomaiya A., et al., Surface-modified compressed expanded graphite for increased salt hydrate phase change material thermal conductivity and stability. ACS Applied Energy Materials, 2023, 6(17): 8775–8786.

[24]

Yu X., Tao Y., Preparation and characterization of paraffin/expanded graphite composite phase change materials with high thermal conductivity. International Journal of Heat and Mass Transfer, 2022, 198: 123433.

[25]

Li W., Gao C., Hou A., et al., One-pot in situ synthesis of expandable graphite-encapsulated paraffin composites for thermal energy storage. Chemical Engineering Journal, 2024, 481: 148541.

[26]

Li C., Ding Y., Zhou Z., et al., Parameter optimization and sensitivity analysis of a Lithium-ion battery thermal management system integrated with composite phase change material. Applied Thermal Engineering, 2023, 228: 120530.

[27]

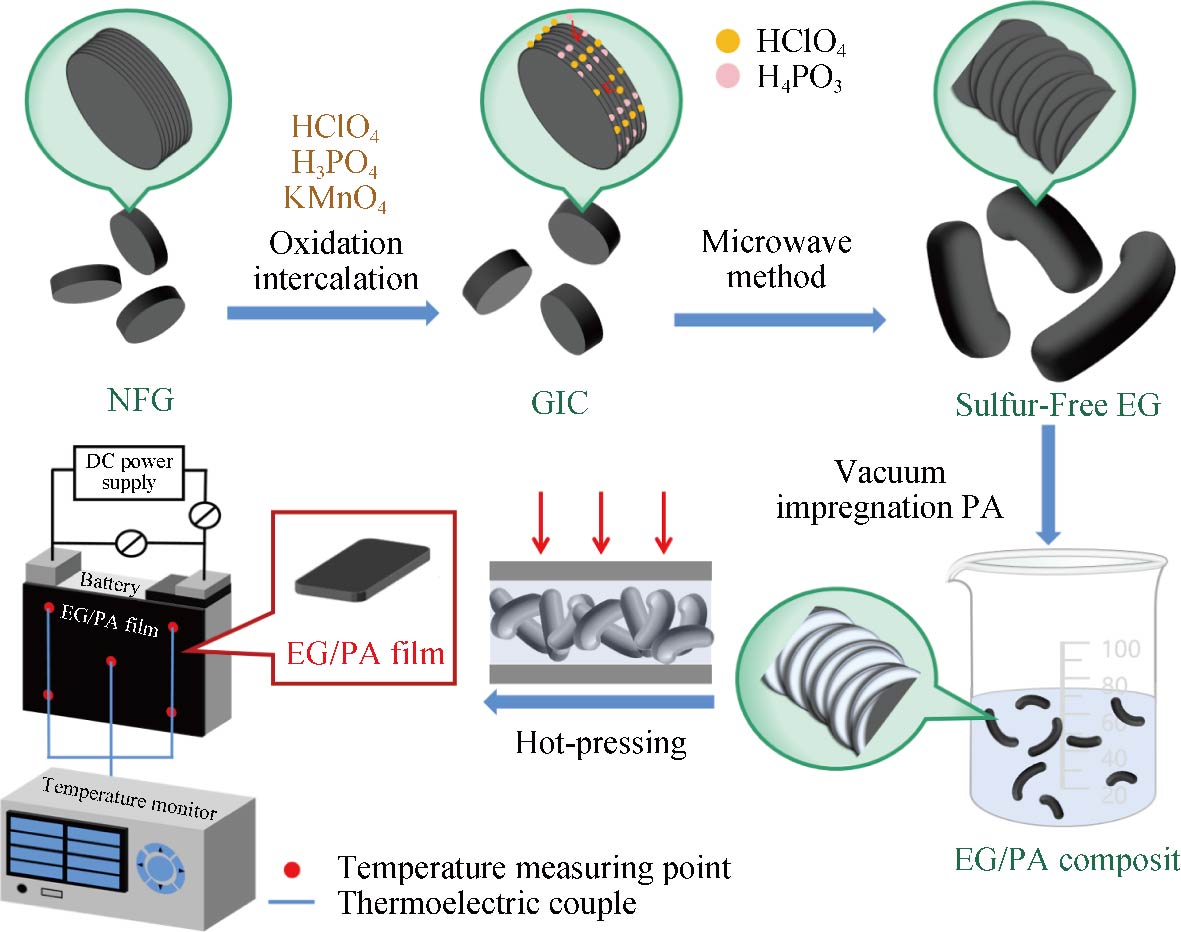

Liu T., Zhang R., Zhang X., et al., One-step room-temperature preparation of expanded graphite. Carbon, 2017, 119: 544–547.

[28]

Ushak S., Song W., Marín P., et al., A review on phase change materials employed in Li-ion batteries for thermal management systems. Applied Materials Today, 2024, 37: 102021.

[29]

Deng R., Chu F., Yu H., et al., Electrochemical performance of expanded graphite prepared from anthracite via a microwave method. Fuel Processing Technology, 2022, 227: 107100.

[30]

Liu Y., Zhou Z., Wu W., et al., Numerical simulations on hybrid thermal management of mini-channel cold plate and PCM for lithium-ion batteries. Applied Thermal Engineering, 2024, 250: 123475.

[31]

Kr H.N., Kannan S., Ramadoss A., Role of phase change materials in examining the discharge behavior of Li-ion batteries using ANSYS fluent. ACS Applied Electronic Materials, 2024, 6(7): 5163–5172.

[32]

Ardestani M.M., Mahpishanian S., Rad B.F., et al., Preparation and characterization of room-temperature chemically expanded graphite: Application for cationic dye removal. Korean Journal of Chemical Engineering, 2022, 39(6): 1496–1506.

[33]

Zhou L., Gao Y., Gong H., et al., Application of an inorganic sulfur-modified expanded graphite anode for sodium storage at low temperatures. Sustainable Energy & Fuels, 2021, 5(20): 5160–5165.

[34]

Chakraborty A., Noh J., Mach R., et al., Thermal energy storage composites with preformed expanded graphite matrix and paraffin wax for long-term cycling stability and tailored thermal properties. Journal of Energy Storage, 2022, 52: 104856.

[35]

He J., Yuan M., Ren H., et al., The electrochemical preparation and characterization of sulfur-free expanded graphite. Journal of Chemical Sciences, 2023, 135(1): 17.

[36]

Chen Y., Hsiao C., Ya J., et al., Preparation of expanded graphite with (NH4)2S2O8 and H2SO4 by using microwave irradiation. Journal of the Taiwan Institute of Chemical Engineers, 2024, 154: 105026.

[37]

Wei Q., Xu L., Tang Z., et al., High-performance expanded graphite from flake graphite by microwave-assisted chemical intercalation process. Journal of Industrial and Engineering Chemistry, 2023, 122: 562–572.

[38]

Ribeiro D.S., Santos J.C.C., Grieger S., et al., Measuring the surface area concentration and specific surface area of mass-produced graphene nanoflakes via fluorescence quenching. ACS Applied Nano Materials, 2023, 6(13): 11198–11210.

[39]

Saikam L., Arthi P., Senthil B., et al., A review on exfoliated graphite: synthesis and applications. Inorganic Chemistry Communications, 2023, 152: 110685.

[40]

Sun J., Li L., Yu R., et al., Synthesis and microwave absorption properties of sulfur-free expanded graphite/ Fe3O4 composites. Molecules, 2020, 25(13): 3044.

[41]

Yu R., Wang X., Tao G., et al., Study on preparation and heat transfer enhancement of expanded graphite/paraffin composites. Journal of Physics: Conference Series, 2024, 2671(1): 12021.

[42]

Feng L., Wu J., Sun W., et al., Effects of pore structure and pore size of expanded graphite on the properties of paraffin wax/expanded graphite composite phase change materials. Energies, 2022, 15(12): 4201.

[43]

Zhang G., Sun Y., Wu C., et al., Low-cost and highly thermally conductive lauric acid-paraffin-expanded graphite multifunctional composite phase change materials for quenching thermal runaway of lithium-ion battery. Energy Reports, 2023, 9: 2538–2547.

[44]

Lu B., Zhang Y., Sun D., et al., Experimental investigation on thermal properties of paraffin/expanded graphite composite material for low temperature thermal energy storage. Renewable Energy, 2021, 178: 669–678.

[45]

Shaker M., Qin Q., Zhaxi D., et al., Improving the cold thermal energy storage performance of paraffin phase change material by compositing with graphite, expanded graphite, and graphene. Journal of Materials Engineering and Performance, 2023, 32(22): 10275–10284.

[46]

Lin X., Zhang X., Liu L., et al., Polymer/expanded graphite-based flexible phase change material with high thermal conductivity for battery thermal management. Journal of Cleaner Production, 2022, 331: 130014.

[47]

Yang K., Ling Z., Fang X., et al., Introducing a flexible insulation network to the expanded graphite-based composite phase change material to enhance dielectric and mechanical properties for battery thermal management. Journal of Energy Storage, 2023, 66: 107486.