[1]

Yu V., Matsenko V., Antonov V., Advances in water-ring vacuum pumps and compressors. Chemical & Petroleum Engineering, 1997, 33(5): 522–523.

[2]

Zhang Y., Zhou F., Li J., et al., Application and research of new energy-efficiency technology for liquid-ring vacuum pump based on turbulent drag reduction theory. Vacuum, 2019, 172: 109076.

[3]

Xu S., Long X., Ji B., et al., Vortex dynamic characteristics of unsteady tip clearance cavitation in a waterjet pump determined with different vortex identification methods. Journal of Mechanical Science and Technology, 2019, 33: 5901–5912.

[4]

Shen X., Zhang D., Xu B., et al., Experimental and numerical investigation on the effect of tip leakage vortex induced cavitating flow on pressure fluctuation in an axial flow pump. Renewable Energy, 2021, 163: 1195–1209.

[5]

Duan X., Tang F., Duan W., et al., Experimental investigation on the correlation of pressure pulsation and vibration of axial flow pump. Advances in Mechanical Engineering, 2019, 11(11): 1–11.

[6]

Pandey A., Khan S., Dekker R., et al., Multiphase flow in a liquid-ring vacuum pump. Journal of Fluids Engineering, 2021, 143(1): 011404.

[7]

Li B., Mu G., Luo L., et al., Effect of combined boundary layer suction on the separation control in a highly loaded transonic compressor cascade. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2024, 238(2): 217–231.

[8]

Zaccara M., Paolillo G., Cafiero G., et al., Near field evolution of wingtip vortices under synthetic-jet based control. Aerospace Science and Technology, 2024, 148: 109068.

[9]

Benmoussa A., Páscoa J.C., Enhancement of a cycloidal self-pitch vertical axis wind turbine performance through DBD plasma actuators at low tip speed ratio. International Journal of Thermofluids, 2023, 17: 100258.

[10]

Zhang D., Liu D., Liu X., et al., Unsteady effects of a winglet on the performance of horizontal-axis tidal turbine. Renewable Energy, 2024, 225: 120334.

[11]

Ding S., Chen S., Li Z., et al., Stability enhancement using a new combined casing treatment strategy in an ultra-highly loaded transonic compressor rotor. Aerospace Science and Technology, 2024, 154: 109505.

[12]

Zeng F., Zhang W., Wang Y., et al., Effects of squealer geometry of turbine blade tip on the tip-leakage flow and loss. Journal of Thermal Science, 2021, 30: 1376–1387.

[13]

Li B., Synthetic jet and its application in active flow control. Nanjing University of Aeronautics and Astronautics, 2008.

[14]

Mei Y., Zheng C., Hua Y., et al., Active control for the flow around various geometries through deep reinforcement learning. Fluid Dynamics Research, 2022, 54(1): 015510.

[15]

Wu Y., Li Y., Progress and outlook of plasma flow control. Acta Aeronautica et Astronautica Sinica, 2015, 36(2): 381–405.

[16]

Zheng J., Flow separation control over an airfoil using continuous alternating current plasma actuator. Chinese Physics B, 2021, 30(3): 034702.

[17]

Singh D.K., Parmar D.L., Sharma A., Flow separation control in a two-airfoil system by trailing edge modification and active flow control. Progress in Computational Fluid Dynamics, 2023, 23(6): 352–363.

[18]

Li G., Xu Y., Yang L., et al., Low speed axial compressor stall margin improvement by unsteady plasma actuation. Journal of Thermal Science, 2014, 23(2): 114–119.

[19]

Zhang H., Wu Y., Yu X., et al., Experimental investigation on the plasma flow control of axial compressor rotating stall. American Society of Mechanical Engineers, 2019, Paper No: GT2019-90609.

[20]

Yue L., Wang Y., Ma X., et al., Active flow control of low-pressure turbine by dielectric barrier discharge plasma actuator. Acta Physica Polonica: A, 2022, 142(2): 233–241.

[21]

Yu J., Lu Y., Wang Y., et al., Experimental study on the plasma actuators for the tip leakage flow control in a turbine cascade. Aerospace Science and Technology, 2022, 121: 107195.

[22]

Zhang R., Guo G., Experimental study on gas-liquid transient flow in liquid-ring vacuum pump and its hydraulic actuation. Vacuum, 2020, 171: 109025.

[23]

Guo G., Zhang R., Jiang L., et al., Study on mechanism of unsteady gas-liquid two-phase flow in liquid-ring vacuum pump. Vacuum, 2024, 222: 113077.

[24]

Guo G., Zhang R., Experimental study on pressure fluctuation characteristics of gas-liquid flow in liquid-ring vacuum pump. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2022, 44(6): 1–13.

[25]

Guo G., Zhang R., Yang J., et al., Performance optimization of liquid-ring pumps based on Gappy POD surrogate model. Modern Physics Letters B, 2022, 36(3): 2150558.

[26]

Zhang R., Liang M., Yang J., et al., Optimization of the liquid-ring pump case based on DFFD method. Paiguan Jixie Gongcheng Xuebao/Journal of Drainage and Irrigation Machinery Engineering, 2018, 36(12): 1222–1226, 1239.

[27]

Zhang R., Li R., Zhang J., Analysis of inner flow field and its hydraulic performance of liquid-ring pump with splitter blades. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(4): 122–129.

[28]

Zhang R., Tian L., Guo G., et al., Gas-liquid two-phase flow in the axial clearance of liquid-ring pumps. Journal of Mechanical Science and Technology, 2020, 34: 791–800.

[29]

Wei X., Zhang R., The axial tip clearance leakage analysis of the winglet and composite blade tip for the liquid-ring vacuum pump. Vacuum, 2022, 200: 111027.

[30]

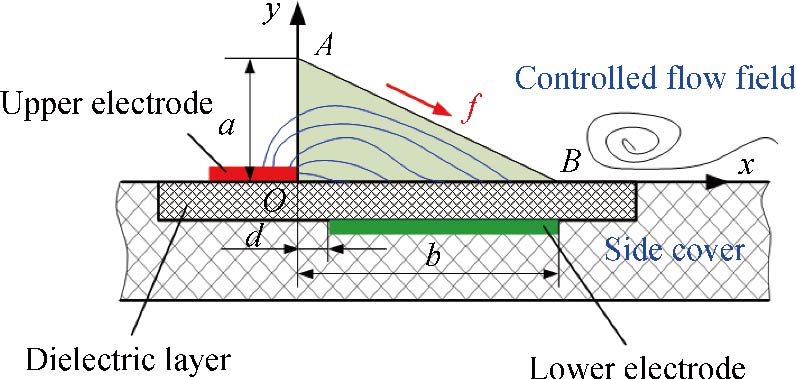

Guo G., Wang J., Zhang, R., et al., Numerical study on plasma control of axial tip clearance leakage flow in liquid-ring vacuum pump. Nongye Jixie Xuebao/Transactions of the Chinese Society of Agricultural Machinery, 2022, 53(09): 160–167.

[31]

Matsunuma T., Segawa T., Vortex structure for reducing tip leakage flow of linear turbine cascade using dielectric barrier discharge plasma actuator. Aerospace Science and Technology, 2023, 136: 108215.

[32]

Wang Z., Yu J., Chen F., et al., Effect of multiple DBD plasma actuators on the tip leakage flow structure and loss of a turbine cascade. International Journal of Heat and Fluid Flow, 2019, 77: 377–387.

[33]

Zhang W., Shi Z., Li G., et al., Numerical study on dynamic stall flow control for wind turbine airfoil using plasma actuator. Chinese Journal of Theoretical and Applied Mechanics, 2020, 52(6): 1678–1689.

[34]

Saddoughi S., Bennett G., Boespflug M., et al., Experimental investigation of tip clearance flow in a transonic compressor with and without plasma actuators. Journal of Turbomachinery, 2015, 137(4): 041008.

[35]

Zhang H., Wu Y., Li Y., et al., Control of compressor tip leakage flow using plasma actuation. Aerospace Science and Technology, 2019, 86: 244–255.

[36]

Hirt C.W., Nichols B.D., Volume of fluid (VOF) method for the dynamics of free boundaries. Journal of Computational Physics, 1981, 39(1): 201–225.

[37]

Ferziger J.H., Perić M., Computational methods for fluid dynamics. New York: Springer, 2002.

[38]

Yakhot V., Orszag S.A., Thangam S., et al., Development of turbulence models for shear flows by a double expansion technique. Physics of Fluids A: Fluid Dynamics, 1992, 4(7): 1510–1520.

[39]

Shyy W., Jayaraman B., Andersson A., Modeling of glow discharge-induced fluid dynamics. Journal of Applied Physics, 2002, 92(11): 6434–6443.