[1]

IEA (2024), Renewables 2023, IEA. IEA, 2024. Renewables 2023, IEA. https://www.iea.org/reports/renewables-2023.

[2]

Tarroja B., Mueller F., Eichman J D., et al., Spatial and temporal analysis of electric wind generation intermittency and dynamics. Renewable Energy, 2011, 36(12): 3424‒3432.

[3]

Fu Y., Lu Z., Hu W., et al., Research on joint optimal dispatching method for hybrid power system considering system security. Applied Energy, 2019, 238: 147‒163.

[4]

Li F., Chen S., Ju C., et al., Research on short-term joint optimization scheduling strategy for hydro-wind-solar hybrid systems considering uncertainty in renewable energy generation. Energy Strategy Reviews, 2023, 50: 101242.

[5]

Liu T., Yang Z., Duan Y., et al., Techno-economic assessment of hydrogen integrated into electrical/thermal energy storage in PV+Wind system devoting to high reliability. Energy Conversion and Management, 2022, 268: 116067.

[6]

Fu Y., Wang L., Liu M., et al., Performance analysis of coal-fired power plants integrated with carbon capture system under load-cycling operation conditions. Energy, 2023, 276: 127532.

[7]

Hu Y., Zhai R., Liu L., et al., Capacity optimization and performance analysis of wind power- photovoltaic-concentrating solar power generation system integrating different S-CO

2 Brayton cycle layouts. Journal of Cleaner Production, 2023, 433: 139342.

[8]

Zhang H., Liang W., Liu J., et al., Modeling and energy efficiency analysis of thermal power plant with high temperature thermal energy storage (HTTES). Journal of Thermal Science, 2020, 29(4): 1025‒1035.

[9]

Zhai R., Chen Y., Zhao Y., et al., Annual performance analysis of solar aided coal-fired power plant with and without heat storage under various policy conditions. Journal of Thermal Science, 2025, 34(5): 899–912.

[10]

Qin Y., Liu T., Li P., et al., New hybrid CHP system integrating solar energy and exhaust heat thermochemical synergistic conversion with dual-source energy storage. Journal of Thermal Science, 2024, 33(3): 970–984.

[11]

Zhao Y., Song J., Liu M., et al., Thermo-economic assessments of pumped-thermal electricity storage systems employing sensible heat storage materials. Renewable Energy, 2022, 186: 431‒456.

[12]

Stevanovic V.D., Petrovic M.M., Milivojevic S., et al., Upgrade of the thermal power plant flexibility by the steam accumulator. Energy Conversion and Management, 2020, 223: 113271.

[13]

Krüger M., Muslubas S., Loeper T., et al., Potentials of thermal energy storage integrated into steam power plants. Energies, 2020, 13(9): 2226.

[14]

Bauer T., Odenthal C., Bonk A., Molten salt storage for power generation. Chemie Ingenieur Technik, 2021, 93(4): 534‒546.

[15]

Kosman W., Rusin A., Reichel P., Application of an energy storage system with molten salt to a steam turbine cycle to decrease the minimal acceptable load. Energy, 2023, 266: 126480.

[16]

Elfeky K.E., Mohammed A.G., Ahmed N., et al., Thermal and economic evaluation of phase change material volume fraction for thermocline tank used in concentrating solar power plants. Applied Energy, 2020, 267: 115054.

[17]

Edwards J., Bindra H., Sabharwall P., Exergy analysis of thermal energy storage options with nuclear power plants. Annals of Nuclear Energy, 2016, 96: 104‒111.

[18]

Argyrou M.C., Christodoulides P., Kalogirou S.A., Energy storage for electricity generation and related processes: Technologies appraisal and grid scale applications. Renewable and Sustainable Energy Reviews, 2018, 94: 804‒821.

[19]

Akanda M.A.M., Shin D., A synthesis parameter of molten salt nanofluids for solar thermal energy storage applications. Journal of Energy Storage, 2023, 60: 106608.

[20]

Wojcik J.D., Wang J., Technical feasibility study of thermal energy storage integration into the conventional power plant cycle. Energies. 2017, 10(2): 205.

[21]

Wei H., Lu Y., Yang Y., et al., Research on influence of steam extraction parameters and operation load on operational flexibility of coal-fired power plant. Applied Thermal Engineering, 2021, 195: 117226.

[22]

Kosman W., Rusin A., Reichel P., Application of an energy storage system with molten salt to a steam turbine cycle to decrease the minimal acceptable load. Energy, 2023, 266: 126480.

[23]

Zhang Q., Dong J., Chen H., et al., Dynamic characteristics and economic analysis of a coal-fired power plant integrated with molten salt thermal energy storage for improving peaking capacity. Energy, 2024, 290: 130132.

[24]

Cao R., Lu Y., Yu D., et al., A novel approach to improving load flexibility of coal-fired power plant by integrating high temperature thermal energy storage through additional thermodynamic cycle. Applied Thermal Engineering, 2020, 173: 115225.

[25]

Hu W., Sun R., Zhang K., et al., Thermoeconomic analysis and multiple parameter optimization of a combined heat and power plant based on molten salt heat storage. Journal of Energy Storage, 2023, 72: 108698.

[26]

Yong Q., Tian Y., Qian X., et al., Retrofitting coal-fired power plants for grid energy storage by coupling with thermal energy storage. Applied Thermal Engineering, 2022, 215: 119048.

[27]

Xu J., Liu W., Wang Z., et al., Comparative investigation on the thermodynamic performance of coal-fired power plant integrating with the molten salt thermal storage system. Journal of Energy Storage, 2024, 89: 111738.

[28]

Zhang K., Liu M., Zhao Y., et al., Design and performance evaluation of a new thermal energy storage system integrated within a coal-fired power plant. Journal of Energy Storage, 2022, 50: 104335.

[29]

Wang B., Ma H., Ren S., et al., Effects of integration mode of the molten salt heat storage system and its hot storage temperature on the flexibility of a subcritical coal-fired power plant. Journal of Energy Storage, 2023, 58: 106410.

[30]

Chen C., Ge Z., Zhang Y., Study of combined heat and power plant integration with thermal energy storage for operational flexibility. Applied Thermal Engineering, 2023, 219: 119537.

[31]

Ma T., Li Z., Lv K., et al., Design and performance analysis of deep peak shaving scheme for thermal power units based on high-temperature molten salt heat storage system. Energy, 2024, 288: 129557.

[32]

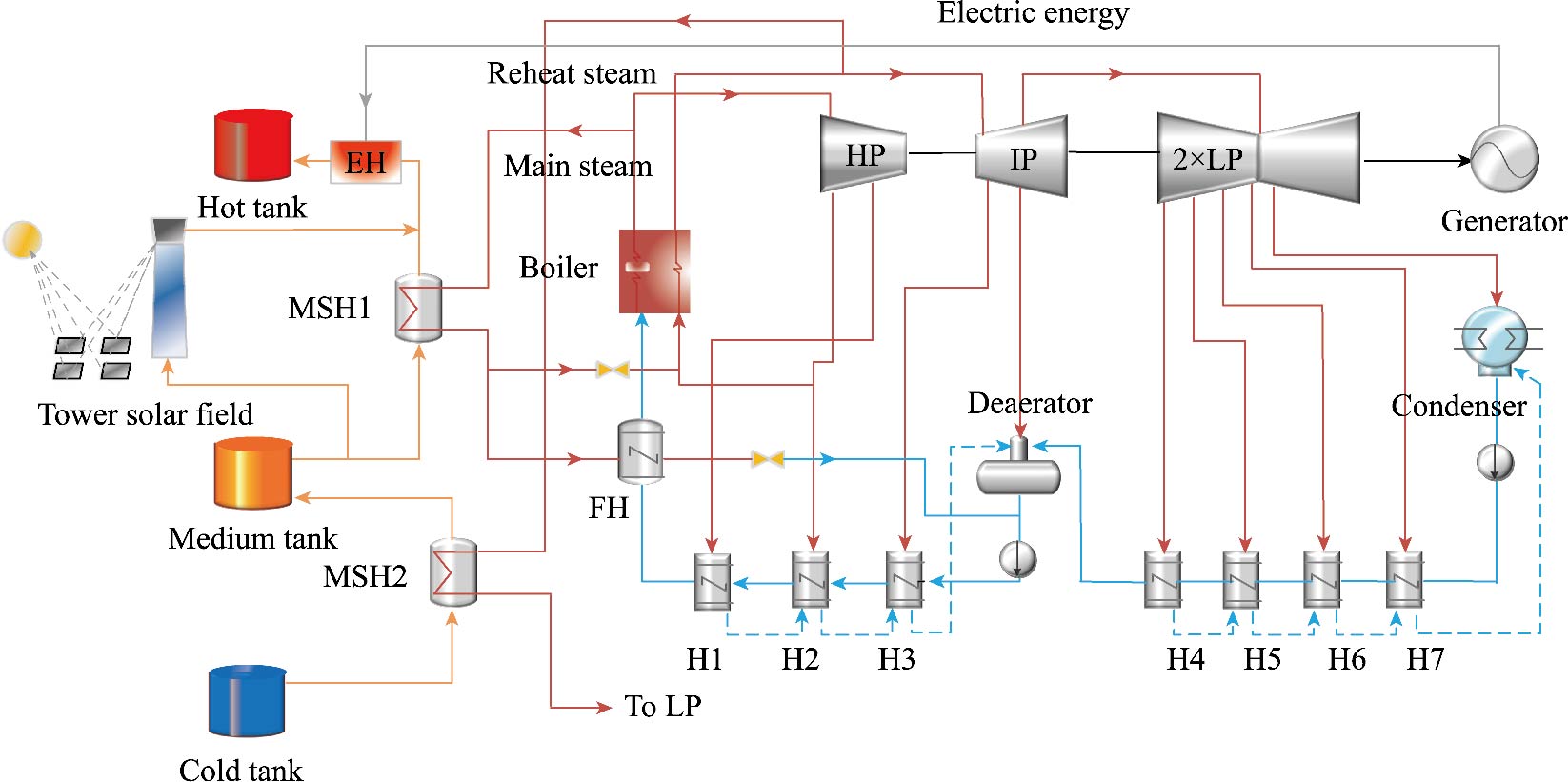

Jiang Y., Duan L., Tong Y., et al., Collaborative optimization of thermal and economic performances of a tower solar aided coal-fired power generation system. Applied Thermal Engineering, 2022, 214: 118885.

[33]

Li C., Sun Y., Bi T., et al., Performance enhancement of a solar-assisted pulverized coal power system by integrating a supercritical CO2 cycle. Renewable Energy, 2023, 219: 119501.

[34]

Li C., Zhai R., Zhang B., et al., Thermodynamic performance of a novel solar tower aided coal-fired power system. Applied Thermal Engineering, 2020, 171: 115127.

[35]

Zhai R., Liu H., Chen Y., et al., The daily and annual technical-economic analysis of the thermal storage PV-CSP system in two dispatch strategies. Energy Conversion and Management, 2017, 154: 56‒67.

[36]

Yu Q., Fu P., Yang Y., et al., Modeling and parametric study of molten salt receiver of concentrating solar power tower plant. Energy, 2020, 200: 117505.

[37]

Liu H., Zhai R., Fu J., et al., Optimization study of thermal-storage PV-CSP integrated system based on GA-PSO algorithm. Solar Energy, 2019, 184: 391‒409.

[38]

Collado F.J., Guallar J., A review of optimized design layouts for solar power tower plants with campo code. Renewable and Sustainable Energy Reviews, 2013, 20: 142‒154.

[39]

Sassi G., Some notes on shadow and blockage effects. Solar Energy, 1983. 31(3): 331‒333.

[40]

Liu H., Zhai R., Patchigolla K., et al., Performance analysis of a novel combined solar trough and tower aided coal-fired power generation system. Energy, 2020, 201: 117597.

[41]

Petela R., Exergy of undiluted thermal radiation. Solar Energy, 2003, 74(6): 469‒488.

[42]

Zhai R., Liu H., Li C., et al., Analysis of a solar-aided coal-fired power generation system based on thermo-economic structural theory. Energy, 2016, 102: 375‒387.

[43]

Xue X., Han W., Wang Z., et al., Proposal and assessment of a solar-coal thermochemical hybrid power generation system. Applied Thermal Engineering, 2023, 219: 119584.

[44]

Zhao Y., Liu M., Wang C., et al., Exergy analysis of the regulating measures of operational flexibility in supercritical coal-fired power plants during transient processes. Applied Energy, 2019, 253: 113487.

[45]

Zhu Y., Zhai R., Peng H., et al., Exergy destruction analysis of solar tower aided coal-fired power generation system using exergy and advanced exergetic methods. Applied Thermal Engineering, 2016, 108: 339‒346.

[46]

Pacheco J.E., Bradshaw R.W., Dawson D.B., et al., Final test and evaluation results from the Solar Two project. Report No. SAND2002-0120, Sandia National Laboratories, Albuquerque, NM, 2002.

[47]

Li B., Cao Y., He T., et al., Thermodynamic analysis and operation strategy optimization of coupled molten salt energy storage system for coal-fired power plant. Applied Thermal Engineering, 2024, 236: 121702.

[48]

Meng Y., Cao Y., Li J., et al., The real cost of deep peak shaving for renewable energy accommodation in coal-fired power plants: Calculation framework and case study in China. Journal of Cleaner Production, 2022, 367: 132913.

[49]

Seider W.D., Lewin D.R., Product and process design principles. John Wiley & Sons Inc, 2016.

[50]

Wang L., Yang Y., Dong C., et al., Parametric optimization of supercritical coal-fired power plants by MINLP and differential evolution. Energy Conversion and Management, 2014, 85: 828‒838.

[51]

Wu S., Zhou C., Doroodchi E., et al., Techno-economic analysis of an integrated liquid air and thermochemical energy storage system. Energy Conversion and Management, 2020, 205: 112341.