[1]

Yang W.B., Han S.B., Li W., Geological factors controlling deep geothermal anomalies in the Qianjiaying Mine, China. International Journal of Mining Science and Technology, 2020, 30: 839–847.

[2]

Yang X.J., Han Q.Y., Pang J.W., et al., Progress of heat-hazard treatment in deep mines. Mining Science and Technology (China), 2011, 21: 295–299.

[3]

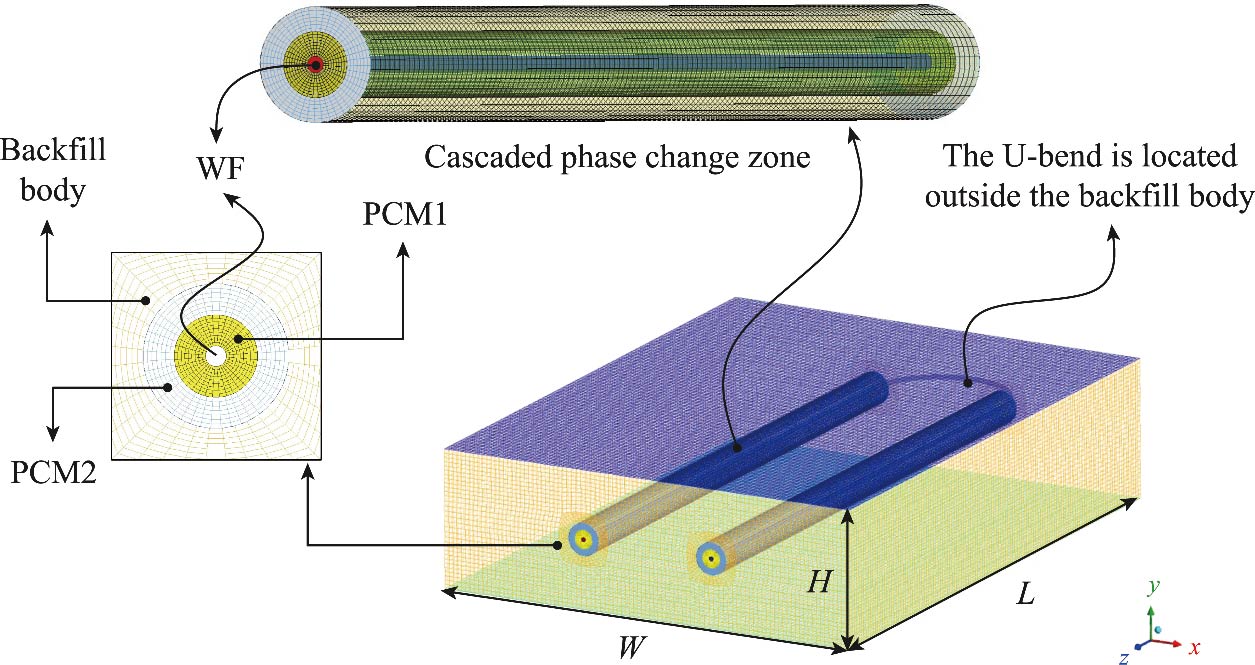

Zhang B., Xue P.Y., Liu L., et al., Exploration on the method of ore deposit-geothermal energy synergetic mining in deep backfill mines. Journal of China Coal Society, 2021, 46(9): 2824–2837.

[4]

Huang Y.H., Kong Y.L., Cheng Y.Z., et al., Evaluating the long-term sustainability of geothermal energy utilization from deep coal mines. Geothermics, 2023, 107: 102584.

[5]

Islama M.T., Nabib M.N., Arefinc M.A., et al., Trends and prospects of geothermal energy as an alternative source of power: A comprehensive review. Heliyon, 2022, 8(2022): e11836.

[6]

Bao T., Meldrum J., Green C., et al., Geothermal energy recovery from deep flooded copper mines for heating. Energy Conversion and Management, 2019, 183: 604–616.

[7]

Lu X., Tong X.L., Du X.P., et al., Effect of wellbore layout and varying flow rate on fluid flow and heat transfer of deep geothermal mining system. Thermal Science and Engineering Progress, 2023, 42: 101870.

[8]

Wang P.T., Wang S.M., Wang G.Y., et al., Exploitation technology and productivity analysis of hydrothermal geothermal multi-branch wells. Geothermics, 2024, 117: 102883.

[9]

Zhao Y.J., Liu L., Wen D., Zhang B., Zhang X.Y., Huan C., Experimental study of horizontal ground heat exchangers embedded in the backfilled mine stopes. Geothermics, 2022, 100(2022): 102344.

[10]

Stathopoulosa N., Mankibia M.E., Santamouris M., Numerical calibration and experimental validation of a PCM-air heat exchanger model. Applied Thermal Engineering, 2017, 114(2017): 1064–1072.

[11]

Javidan M., Asgari M., Gholinia M., et al., Thermal energy storage inside the chamber with a brick wall using the phase change process of paraffinic materials: A numerical simulation. Theoretical and Applied Mechanics Letters, 2022, 12: 100329.

[12]

Shahlaei S., Hassankolaei M.G., MHD boundary layer of GO-H

2O nanoliquid flow upon stretching plate with considering nonlinear thermal ray and Joule heating effect. Heat Transfer-Asian Research, 2019, 48(8): 4152–4173.

[13]

Ghoreishi S.A., Hassani F., Abbasy F., Numerical and experimental study of geothermal heat extraction from backfilled mine stopes. Applied Thermal Engineering, 2015, 90: 1119–1130.

[14]

Zheng W.B., Yang S.Q., Li W., et al., Experimental study on thermal performance of phase change heat storage device with rectangular shell structure. Applied Thermal Engineering, 2022, 214: 118897.

[15]

Dhaidan N., Hashim H., Abbas A., et al., Discharging of PCM in various shapes of thermal energy storage systems: a review. Journal of Thermal Science, 2023, 32(03): 1124–1154.

[16]

Dukhan W.A., Dhaidan N.S., Al Hattab T.A., et al., Phase change of paraffin inside heat exchangers: an experimental study. International Journal of Environmental Science and Technology, 2022, 19(4): 3155–3164.

[17]

Li W., Wang Y.X., Zhang X., et al., Study on thermal storage performance of heat storage tank with PCM balls. Energy & Buildings, 2023, 278: 112669.

[18]

Liu H.F., Rodriguez-Dono A., Zhang J.X., et al., A new method for exploiting mine geothermal energy by using functional cemented paste backfill material for phase change heat storage: Design and experimental study. Journal of Energy Storage, 2022, 54: 105292.

[19]

Wang Y.R., Hou J., Li C.J., et al., Performance analysis of the phase-change heat-storage tank based on numerical simulation. Applied Thermal Engineering, 2023, 235: 121370.

[20]

Omojaro P., Breitkopf C., Investigating and modeling of simultaneous charging and discharging of a PCM heat exchanger. Energy Procedia, 2014, 48: 413–422.

[21]

Jang D., Yoon H.N., Yang B., et al., Cyclic heat-generation and storage capabilities of self-heating cementitious composite with an addition of PCM. Construction and Building Materials, 2023, 369: 130512.

[22]

Al-Salami H.A., Dhaidan N.S., Abbas H.H., et al., Review of PCM charging in latent heat thermal energy storage systems with fins. Thermal Science and Engineering Progress, 2024, 51: 102640.

[23]

Hadi M., Pourfallah M., Shaker B., et al., Simulation of a solar power plant with parabolic receivers in several parts of Iran in the presence of latent heat thermal energy storage system. Thermal Science and Engineering Progress, 2022, 30: 101249.

[24]

Siahchehrehghadikolaei S., Gholinia M., Ghadikolaei S.S., et al., A CFD modeling of CPU cooling by eco-friendly nanofluid and fin heat sink passive cooling techniques. Advanced Powder Technology, 2022, 33(11): 103813.

[25]

Nabi H., Gholinia M., Ganji D.D., Employing the (SWCNTs-MWCNTs)/H2O nanofluid and topology structures on the microchannel heatsink for energy storage: A thermal case study. Case Studies in Thermal Engineering, 2023, 42: 102697.

[26]

Afaynou I., Faraji H., Choukairy K., et al., Effectiveness of a PCM-based heat sink with partially filled metal foam for thermal management of electronics. International Journal of Heat and Mass Transfer, 2024, 235: 126196.

[27]

Sabet S., Buonomo B., Sheremet M.A., et al., Numerical investigation of melting process for phase change material (PCM) embedded in metal foam structures with Kelvin cells at pore scale level. International Journal of Heat and Mass Transfer, 2023, 214: 124440.

[28]

Dhaidan N.S., AL-Jethelan M., Study on the effect of nanoparticle dispersion on the melting of PCM in hemicylindrical cell. 12th IIR Conference on Phase-Change Materials and Slurries for Refrigeration and Air Conditioning, Orford, Canada, 2018, 33: 242–247. DOI: 10.18462/iir.pcm.2018.0033.

[29]

Madih R., Pourfallah M., Gholinia M., et al., Thermofluids analysis of combustion, emissions, and energy in a biodiesel (C11H22O2)/natural gas heavy-duty engine with RCCI mode (Part I: Single/two-stage injection). International Journal of Thermofluids, 2022, 16: 100227.

[30]

Zadeh M.N., Pourfallah M., Safari S.S., et al., Performance assessment and optimization of a helical Savonius wind turbine by modifying the Bach’s section. SN Applied Sciences, 2021, 3(8): 739–750. DOI: 10.1007/s42452-021-04731-0.

[31]

Madihi R., Pourfallah M., Gholinia M., et al., Thermofluids analysis of combustion, emissions, and energy in a biodiesel (C11H22O2) / natural gas heavy-duty engine with RCCI mode (Part II: Fuel injection time/ Fuel injection rate). International Journal of Thermofluids, 2022, 16: 100200.

[32]

Armin M., Gholinia M., Comparative evaluation of energy, performance, and emission characteristics in dual-fuel (CH4/Diesel) heavy-duty engine with RCCI combustion mode. Results in Engineering, 2022, 16: 100766.

[33]

Zhang Z.B., Liang M., Cong Y., Analysis of thermodynamic performance of cascaded latent heat storage using variable diameter capsules. Journal of Energy Storage, 2022, 55: 105595.

[34]

Choure B.K., Alam T., Kumar R., A review on heat transfer enhancement techniques for PCM based thermal energy storage system. Journal of Energy Storage, 2023, 72: 108161.

[35]

Shen Y.L., Mazhar A.R., Liu S.L., Comprehensive review on cascaded latent heat storage technology: Recent advances and challenges. Journal of Energy Storage, 2022, 55: 105713.

[36]

Liu Y.G., Zhang J.Y., Li H.J., et al., Numerical study on stratification performance of cascaded three-layered packed-bed in the thermal storage process. Applied Thermal Engineering, 2023, 219: 119669.

[37]

Zhang Z.B., Liang M., Ci Z.Q., Thermal performance analysis of latent heat thermal energy storage with cascaded PCMs capsules under varying inlet temperature. Journal of Energy Storage, 2023, 62: 106893.

[38]

Tian L., Wang J.J., Zhao L., et al., Unsteady-state thermal performance analysis of cascaded packed-bed latent thermal storage in solar heating system. Energy, 2023, 272: 127053.

[39]

Fan M., Suo H.X., Yang H., et al., Experimental study on thermophysical parameters of a solar assisted cascaded latent heat thermal energy storage (CLHTES) system. Energy, 2022, 256: 124639.

[40]

Li W., Zhang Y.L., Zhang X., et al., Studies on performance enhancement of heat storage system with multiple phase change materials. Journal of Energy Storage, 2022, 47: 103585.

[41]

Lu S.L., Lin Q.Y., Xu B.W., et al., Thermodynamic performance of cascaded latent heat storage systems for building heating. Energy, 2023, 282: 128752.

[42]

Elbahjaoui R., Improvement of the thermal performance of a solar triple concentric-tube thermal energy storage unit using cascaded phase change materials. Journal of Energy Storage, 2021, 42: 103047.

[43]

Zhang X.Y., Xu M.Y., Liu L., et al., Experimental study on thermal and mechanical properties of cemented paste backfill with PCM. Journal of Materials Research and Technology, 2020, 9(2): 2164–2175.

[44]

Shi C., Application of phase change energy storage material RT28 in building walls. Anhui Jianzhu University, Anhui, China, 2015.

[45]

Ebrahimi A., Hosseini M.J., Ranjbar A.A., et al., Melting process investigation of PCMs in a shell and tube heat exchanger enhanced with heat pipe. Renewable Energy, 2019, 138: 378–394.

[46]

Zhang X.Y., Xu M.Y., Liu L., et al., Heat storage/heat release of phase-change filling body with casing heat exchanger for extracting geothermal energy. Journal of Thermal Science, 2023, 32(03): 1171–1189.

[47]

Zhang X.Y., Zhao M., Liu L., et al., Numerical simulation on heat storage performance of backfill body based on tube-in-tube heat exchanger. Construction and Building Materials, 2020, 265(2020): 120340.

[48]

Ameen R., ELSihy E.S., Shedid M., et al., Effect of volume fractions of phase change materials on the dynamic performance of two- and three-stage cascaded latent heat thermal energy storage systems. Journal of Energy Storage, 2024, 85: 111026.

[49]

Ye R.D., Lin W.Z., Fang X.M., et al., A numerical study of building integrated with CaCl

2·6H

2O/expanded graphite composite PCM. Applied Thermal Engineering, 2017, 126: 480–488.

[50]

Mao Q.J., Zhang Y.F., Study on the thermal storage performance of a new cascade structure phase change thermal storage tank. Journal of Energy Storage, 2022, 56: 106155.

[51]

Erol S., Francois B., Efficiency of various grouting materials for borehole heat exchangers. Applied Thermal Engineering, 2014, 70: 788–799.