[1] Yan X., Duan C., Yu S., et al., Recent advances on CO2 reduction reactions using single-atom catalysts. Renewable & Sustainable Energy Reviews, 2024, 190: 114086.

[2] Cui R., Ren Q., Zhou L., Zhang S., A novel coal purification-combustion system: Product and efficiency of coal purification process. Applied Thermal Engineering, 2024, 249: 123361.

[3] Wang G., Zhang Z., Lin J., Multi-energy complementary power systems based on solar energy. Renewable and Sustainable Energy Reviews, 2024, 199: 114464.

[4] Khan M.I., Gutiérrez-Alvarez R., Asfand F., et al., The economics of concentrating solar power (CSP): Assessing cost competitiveness and deployment potential. Renewable and Sustainable Energy Reviews, 2024, 200: 114551.

[5] Zhang X., Zhou S., Liu W., et al., Fabrication of structure-improved, sintering-resistant Li4SiO4 materials for stabilized thermochemical energy storage in concentrated solar power plants. Journal of Energy Storage, 2023, 70: 108078.

[6] Xu Y., Lu C., Luo C., et al., Thermochemical energy storage by calcium looping process that integrates CO2 power cycle and steam power cycle. Fuel Processing Technology, 2023, 242: 107656.

[7] Garcia-Ferrero J., Merchan R.P., Santos M.J., et al., Brayton technology for concentrated solar power plants: Comparative analysis of central tower plants and parabolic dish farms. Energy Conversion and Management, 2022, 271: 116312.

[8] Naumov V., Doninelli M., Di Marcoberardino G., et al., High temperature cesium-sCO2 combined cycle for concentrating solar power applications. Solar Energy, 2024, 275: 112599.

[9] Wang G., Dong B., Chen Z., Design and behaviour estimate of a novel concentrated solar-driven power and desalination system using S-CO2 Brayton cycle and MSF technology. Renewable Energy, 2021, 176: 555–564.

[10] Islam M.T., Huda N., Abdullah A.B., Saidur R., A comprehensive review of state-of-the-art concentrating solar power (CSP) technologies: Current status and research trends. Renewable and Sustainable Energy Reviews, 2018, 91: 987–1018.

[11] Wu S., Peng H., Ao J., Xie L., Design and development of novel LiCl-NaCl-KCl-ZnCl2 eutectic chlorides for thermal storage fluids in concentrating solar power (CSP) applications. Solar Energy Materials and Solar Cells, 2022, 240: 111678.

[12] Huang Y., Zhu P., Xu H., et al., Mn-based oxides modified with MnSiO3 for thermochemical energy storage. Chemical Engineering Journal, 2024, 483: 149437.

[13] Xiong L., Liu D., Duan L., et al., Mass-producible γ-Al2O3/CaCO3 core-shell thermochemical energy storage particles by fluidized bed spray granulation. Chemical Engineering Journal, 2024, 495: 153688.

[14] Xu Y., Lu B., Luo C., Wu F., et al., Na2CO3 promoted CaO-based heat carrier for thermochemical energy storage in concentrated solar power plants. Chemical Engineering Journal, 2022, 435: 134852.

[15] Bian Z., Li Y., Fang Y., et al., Thermochemical heat storage performance and structural stability of SiO2-coated CaO particles under fluidization in CaO/Ca(OH)2 cycles. Journal of Energy Storage, 2024, 85: 111102.

[16] Santamaría Padilla A., Romero-Paredes Rubio H., A thermochemical energy storage materials review based on solid-gas reactions for supercritical CO2 solar tower power plant with a Brayton cycle. Journal of Energy Storage, 2023, 73: 108906.

[17] Han X., Wang L., Ling H., et al., Critical review of thermochemical energy storage systems based on cobalt, manganese, and copper oxides. Renewable and Sustainable Energy Reviews, 2022, 158: 112076.

[18] Tian X.K., Guo S.J., Jiang L., et al., Integrated operation and efficiency analysis of CaCO3/CaO in a fixed-bed reactor for thermochemical energy storage. Energy, 2024, 294: 130867.

[19] Fang Y., Li Y., Zhang J., et al., Cohesive behavior of CaO-based particles in fluidization during CaO/CaCO3 heat storage process: Experiments and molecular dynamics simulations. Chemical Engineering Journal, 2024, 487: 150679.

[20] Hu Y., He W., Cao J., et al., Decorating CaO with dark Ca2MnO4 for direct solar thermal conversion and stable thermochemical energy storage. Solar Energy Materials and Solar Cells, 2022, 248: 111977.

[21] Fang Y., Zhao J., Zhang C., Li Y., Exothermic performance of the calcined limestone determined by exothermic temperature under fluidization during CaCO3/CaO energy storage cycles. Journal of Thermal Science, 2023, 32: 1784–1796.

[22] Sun J., Bai S., Li K., et al., Evaluation of thermochemical energy storage performance of Fe-/Mn-doped, Zr-stabilized, CaO-based composites under different thermal energy storage modes. Acs Applied Energy Materials, 2022, 5: 4903–4915.

[23] Benitez-Guerrero M., Valverde J.M., Sanchez-Jimenez P., et al., Multicycle activity of natural CaCO3 minerals for thermochemical energy storage in concentrated solar power plants. Solar Energy, 2017, 153: 188–199.

[24] Liang S., Aihemaiti A., Cai Y., et al., New insights into stabilizing mechanism of Ca9Al6O18 stabilizing Ca-based sorbents for CO2 cyclic capture under mild conditions. Chemical Engineering Journal, 2023, 474: 145908.

[25] Jin X., Sun H., Tong Y., et al., Porous hollow CaO microsphere synthesized by the template-assisted approach for enhanced CO2 capture. Fuel, 2024, 361: 130638.

[26] Castro-Yanez D., Erans M., Peral A., et al., The key role played by mesoporous alumina as binder for obtaining ultra-hard CaO based pellets for thermochemical heat storage leveraging the CaO/CaCO3 cycle. Journal of Cleaner Production, 2024, 448: 141702.

[27] Benitez-Guerrero M., Valverde J.M., Sanchez-Jimenez P.E., et al., Calcium-Looping performance of mechanically modified Al2O3-CaO composites for energy storage and CO2 capture. Chemical Engineering Journal, 2018, 334: 2343–2355.

[28] Wang K., Gu F., Clough P.T., et al., Porous MgO-stabilized CaO-based powders/pellets via a citric acid-based carbon template for thermochemical energy storage in concentrated solar power plants. Chemical Engineering Journal, 2020, 390: 124163.

[29] Sun H., Li Y., Yan X., et al., Thermochemical energy storage performance of Al2O3/CeO2 co-doped CaO-based material under high carbonation pressure. Applied Energy, 2020, 263: 114650.

[30] Bai S., Sun J., Zhou Z., et al., Structurally improved, TiO2-incorporated, CaO-based pellets for thermochemical energy storage in concentrated solar power plants. Solar Energy Materials and Solar Cells, 2021, 226: 111076.

[31] Zhang Y., Li Y., Fang Y., et al., DFT study of the cooperative promotion of MgO and ZnO on CaCO3/CaO thermochemical heat storage performance of CaO. Energy & Fuels, 2023, 37: 16119–16130.

[32] Liu H., Zhang J., Wei J., Mn and Mg synergistically stabilized CaO as an effective thermochemical material for solar energy storage. Solar Energy Materials and Solar Cells, 2023, 252: 112202.

[33] Chen X., Jin X., Liu Z., et al., Experimental investigation on the CaO/CaCO3 thermochemical energy storage with SiO2 doping. Energy, 2018, 155: 128–138.

[34] Tregambi C., Di Lauro F., Pascual S., et al., Solar-driven calcium looping in fluidized beds for thermochemical energy storage. Chemical Engineering Journal, 2023, 466: 142708.

[35] Da Y., Xuan Y., Teng L., et al., Calcium-based composites for direct solar-thermal conversion and thermochemical energy storage. Chemical Engineering Journal, 2020, 382: 122815.

[36] Zheng H., Liu X., Xuan Y., et al., Thermochemical heat storage performances of fluidized black CaCO3 pellets under direct concentrated solar irradiation. Renewable Energy, 2021, 178: 1353–1369.

[37] Bai S., Sun J., Liu L., et al., Dolomite-derived composites doped with binary ions for direct solar thermal conversion and stabilized thermochemical energy storage. Solar Energy Materials and Solar Cells, 2022, 239: 111659.

[38] Song C., Liu X., Zheng H., et al., Decomposition kinetics of Al- and Fe-doped calcium carbonate particles with improved solar absorbance and cycle stability. Chemical Engineering Journal, 2021, 406: 126282.

[39] Zheng H., Song C., Bao C., et al., Dark calcium carbonate particles for simultaneous full-spectrum solar thermal conversion and large-capacity thermochemical energy storage. Solar Energy Materials & Solar Cells, 2020, 207: 110364.

[40] Da Y., Zhou J., Zeng F., Calcium-based composites directly irradiated by solar spectrum for thermochemical energy storage. Chemical Engineering Journal, 2023, 456: 140986.

[41] Yang Y., Li Y., Zhang C., et al., Thermochemical heat storage and optical properties of red mud/Mn co-doped high alumina cement-stabilized carbide slag in CaO/CaCO3 cycles. Fuel Processing Technology, 2022, 236: 107419.

[42] Cai J., Li Z., First principle-based rate equation theory for the calcination kinetics of CaCO3 in calcium looping. Energy & Fuels, 2024, 38: 8145–8156.

[43] Da Y., Zhou J., Microscopic mechanisms of Mn-doped CaCO3 heat carrier with enhanced optical absorption and accelerated decomposition kinetics for directly storing solar energy. Solar Energy Materials and Solar Cells, 2023, 250: 112103.

[44] Li C., Li Y., Zhang C., et al., Ca3B2O6-modified papermaking white mud for CaCO3/CaO thermochemical energy storage. Chemical Engineering Journal, 2023, 461: 142096.

[45] Gong X., Zhang T., Zhang J., et al., Recycling and utilization of calcium carbide slag—Current status and new opportunities. Renewable and Sustainable Energy Reviews, 2022, 159: 112133.

[46] Li P., Ren Q., Lv Q., Chen R., Review on raw meal and fuel substitution technology for low carbon cement under carbon neutrality. Clean Coal Technology, 2022, 28: 35–42.

[47] Ren Y., Xia T., Qu G., et al., High value-added utilization of secondary aluminum ash & carbide slag: preparation of a high-performance adsorbent for rapid removal of fluoride from wastewater. Reaction Chemistry & Engineering, 2023, 8: 1888–1900.

[48] Sun H., Li Y., Bian Z., et al., Thermochemical energy storage performances of Ca-based natural and waste materials under high pressure during CaO/CaCO3 cycles. Energy Conversion and Management, 2019, 197: 111885.

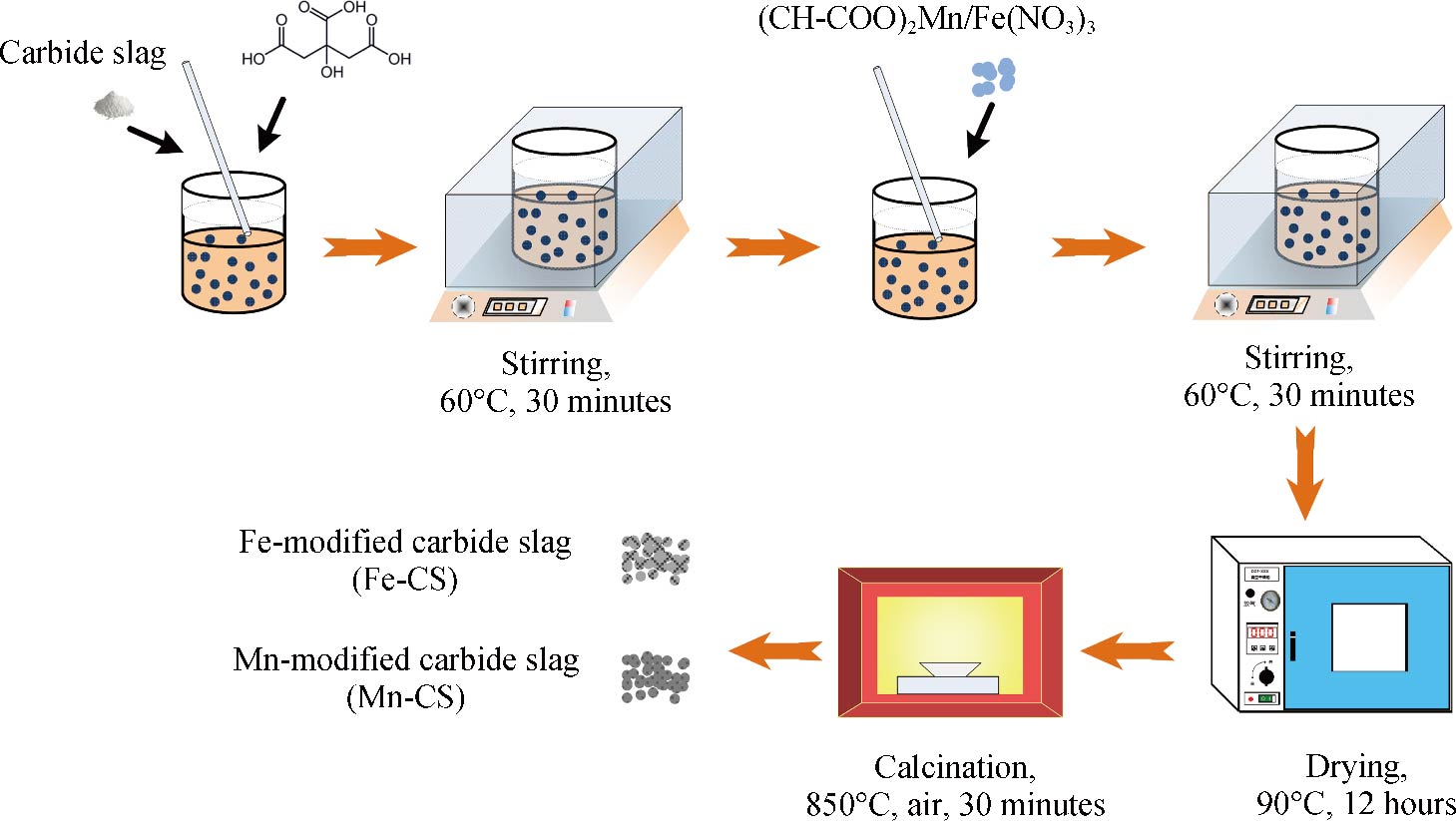

[49] Gao C., Zhang Y., Liu X., et al., Wet combustion synthesis of new thermochemical energy-storage materials based on carbide slag/magnesium oxide using citric acid. Applied Thermal Engineering, 2024, 248: 123302.

[50] Li J., Ma X., Huang X., et al., Improved properties of the Co/Al-doped carbide slag pellet as a potential high-temperature thermal battery by tunable coating strategy. Journal of Environmental Chemical Engineering, 2024, 12: 112108.

[51] Bian Z., Ma X., Lu X., et al., Acceleration mechanisms of Fe and Mn doping on CO2 separation of CaCO3 in calcium looping thermochemical heat storage. Separation and Purification Technology, 2024, 351: 128057.

[52] Benitez-Guerrero M., Valverde J.M., Sanchez-Jimenez P.E., et al., Multicycle activity of natural CaCO3 minerals for thermochemical energy storage in concentrated solar power plants. Solar Energy, 2017, 153: 188–199.

[53] Zhu Y., Wu S., Wang X., Nano CaO grain characteristics and growth model under calcination. Chemical Engineering Journal, 2011, 175: 512–518.

[54] Fang Y., Li Y., Zhang Y., et al., Self-acceleration effect of Mn/Ce-modified carbide slag in CO2 absorption for CaO/CaCO3 energy storage. Separation and Purification Technology, 2025, 357: 130153.

[55] Ding W., Zhao K., Jiang S., et al., Ca2MnO4-layered perovskite modified by NaNO3 for chemical-looping oxidative dehydrogenation of ethane to ethylene. Chinese Journal of Chemical Engineering, 2024, 68: 53–64.

[56] Sánchez Jiménez P.E., Perejón A., Benítez Guerrero M., et al., High-performance and low-cost macroporous calcium oxide based materials for thermochemical energy storage in concentrated solar power plants. Applied Energy, 2019, 235: 543–552.

[57] Feng Y., Zhou T., Kong H., et al., Evaluation of thermodynamic and kinetic properties of carbide slag for fluidized thermochemical heat storage. Journal of Energy Storage, 2022, 56: 105855.

[58] Huang X., Ma X., Li J., et al., Enhancement effects of hydrolysable/soluble Al-type dopants on the efficiency of CaO/CaCO3 thermochemical energy storage. Chemical Engineering Journal, 2024, 490: 151555.