[1] Zhu Z., Zhang J., Zhu S., et al., Digital twin technology for wind turbine towers based on joint load-response estimation: A laboratory experimental study. Applied Energy, 2023, 352: 121953. DOI: 10.1016/j.apenergy.2023.121953.

[2] Liu S., Tian J., Ji Z., et al., Research on multi-digital twin and its application in wind power forecasting. Energy, 2024, 292: 130269. DOI: 10.1016/j.energy.2024.130269.

[3] Zhang J., Zhao X., Digital twin of wind farms via physics-informed deep learning. Energy Conversion and Management, 2023, 293: 117507. DOI: 10.1016/j.enconman.2023.117507.

[4] Wang B., Sun W., Wang H., et al., Research on rapid calculation method of wind turbine blade strain for digital twin. Renewable Energy, 2024, 221: 119783. DOI: 10.1016/j.renene.2023.119783.

[5] Peng C., Zhang Y., Zhang B., et al., A novel ultra-short-term wind power prediction method based on XA mechanism. Applied Energy, 2023, 351: 121905. DOI: 10.1016/j.apenergy.2023.121905.

[6] Zhang J., Zhao X., A novel dynamic wind farm wake model based on deep learning. Applied Energy, 2020, 277: 115552. DOI: 10.1016/j.apenergy.2020.115552.

[7] Semeraro C., Olabi A.G., Aljaghoub H., et al., Digital twin application in energy storage: Trends and challenges. Journal of Energy Storage, 2023, 58: 106347. DOI: 10.1016/j.est.2022.106347.

[8] Li W., Rentemeister M., Badeda J., et al., Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. Journal of Energy Storage, 2020, 30: 101557. DOI: 10.1016/j.est.2020.101557.

[9] Lv Z., Cheng C., Lv H., Digital twins for secure thermal energy storage in building. Applied Energy, 2023, 338: 120907. DOI: 10.1016/j.apenergy.2023.120907.

[10] Collath N., Cornejo M., Engwerth V., et al., Increasing the lifetime profitability of battery energy storage systems through aging aware operation. Applied Energy, 2023, 348: 121531. DOI: 10.1016/j.apenergy.2023.121531.

[11] Bai F., Quan H., Yin R., et al., Three-dimensional multi-field digital twin technology for proton exchange membrane fuel cells. Applied Energy, 2022, 324: 119763. DOI: 10.1016/j.apenergy.2022.119763.

[12] Koo B., Chang S., Kwon H., Digital twin for natural gas infrastructure operation and management via streaming dynamic mode decomposition with control. Energy, 2023, 274: 127317. DOI: 10.1016/j.energy.2023.127317.

[13] Liu K., Zhang S., Smart cities stochastic secured energy management framework in digital twin: Policy frameworks for promoting sustainable urban development in smart cities. Sustainable Energy Technologies and Assessments, 2024, 65: 103720. DOI: 10.1016/j.seta.2024.103720.

[14] Yan M., Gan W., Zhou Y., et al., Projection method for blockchain-enabled non-iterative decentralized management in integrated natural gas-electric systems and its application in digital twin modelling. Applied Energy, 2022, 311: 118645. DOI: 10.1016/j.apenergy.2022.118645.

[15] Song Y., Xia M., Chen Q., et al., A data-model fusion dispatch strategy for the building energy flexibility based on the digital twin. Applied Energy, 2023, 332: 120496. DOI: 10.1016/j.apenergy.2022.120496.

[16] Semeraro C., Aljaghoub H., Abdelkareem M.A., et al., Guidelines for designing a digital twin for Li-ion battery: A reference methodology. Energy, 2023, 284: 128699. DOI: 10.1016/j.energy.2023.128699.

[17] Zhao G., Cui Z., Xu J., et al., Hybrid modeling-based digital twin for performance optimization with flexible operation in the direct air-cooling power unit. Energy, 2022, 254: 124492. DOI: 10.1016/j.energy.2022.124492.

[18] Brynjolfsson E., Mitchell T., What can machine learning do? Workforce implications. Science, 2017, 358(6370): 1530–1534. DOI: 10.1126/science.aap8062.

[19] Lyu W., Liu J., Artificial Intelligence and emerging digital technologies in the energy sector. Applied Energy, 2021, 303: 117615. DOI: 10.1016/j.apenergy.2021.117615.

[20] Weigel P., Fischedick M., Review and categorization of digital applications in the energy sector. Applied Sciences-Basel, 2019, 9(24): 3390. DOI: 10.3390/app9245350.

[21] Cui Z., Xu J., Liu W., et al., Data-driven modeling-based digital twin of supercritical coal-fired boiler for metal temperature anomaly detection. Energy, 2023, 278: 127959. DOI: 10.1016/j.energy.2023.127959.

[22] Tian Z., Xu L., Yuan J., et al., Online performance monitoring platform based on the whole process models of subcritical coal-fired power plants. Applied Thermal Engineering, 2017, 124: 1368–1381. DOI: 10.1016/j.applthermaleng.2017.06.112.

[23] Xu B., Wang J., Wang X., et al., A case study of digital-twin-modelling analysis on power-plant- performance optimizations. Clean Energy, 2019, 3(3): 227–234. DOI: 10.1093/ce/zkz025.

[24] Spinti J.P., Smith P.J., Smith S.T., Atikokan digital twin: Machine learning in a biomass energy system. Applied Energy, 2022, 310: 118436. DOI: 10.1016/j.apenergy.2021.118436.

[25] Chen C., Liu M., Li M., et al., Digital twin modeling and operation optimization of the steam turbine system of thermal power plants. Energy, 2024, 290: 129969. DOI: 10.1016/j.energy.2023.129969.

[26] Spinti J.P., Smith P.J., Smith S.T., et al., Atikokan digital twin, Part B: Bayesian decision theory for process optimization in a biomass energy system. Applied Energy, 2023, 334: 120625. DOI: 10.1016/j.apenergy.2022.120625.

[27] Ram S., Vasudev V., Ku X., Characterization and kinetic analysis of lignocellulosic and algal biochar combustion. International Journal of Fluid Engineering, 2024, 1(2): 452. DOI: 10.1063/5.0194358

[28] Aversano G., Bellemans A., Li Z., et al., Application of reduced-order models based on PCA & Kriging for the development of digital twins of reacting flow applications. Computers & Chemical Engineering, 2019, 121: 422–441. DOI: 10.1016/j.compchemeng.2018.09.022.

[29] Aversano G., Ferrarotti M., Parente A., Digital twin of a combustion furnace operating in flameless conditions: Reduced-order model development from CFD simulations. Proceedings of the Combustion Institute, 2021, 38(4): 5373–5381. DOI: 10.1016/j.proci.2020.06.045.

[30] Lee W., Jang K., Han W., et al., Model order reduction by proper orthogonal decomposition for a 500 MWe tangentially fired pulverized coal boiler. Case Studies in Thermal Engineering, 2021, 28: 101414. DOI: 10.1016/j.csite.2021.101414.

[31] Chen X., Zhong W., Li T., Fast prediction of temperature and chemical species distributions in pulverized coal boiler using POD reduced-order modeling for CFD. Energy, 2023, 276: 127663. DOI: 10.1016/j.energy.2023.127663.

[32] Wang T., Chen X., Zhong W., Air distribution and coal blending optimization to reduce slagging on coal-fired boiler water wall based on POD reduced order modeling for CFD. Fuel, 2024, 357: 129856. DOI: 10.1016/j.fuel.2023.129856.

[33] Xue W., Lu Y., Wang Z., et al., Reconstructing near-water-wall temperature in coal-fired boilers using improved transfer learning and hidden layer configuration optimization. Energy, 2024, 294: 130860. DOI: 10.1016/j.energy.2024.130860.

[34] Xue W., Tang Z., Cao S., et al., A novel online method incorporating computational fluid dynamics simulations and neural networks for reconstructing temperature field distributions in coal-fired boilers. Energy, 2024, 286: 129568. DOI: 10.1016/j.energy.2023.129568.

[35] Long J., Dong M., Zhou J., et al., Fast reconstruction of boiler numerical physical field based on proper orthogonal decomposition and conditional deep convolutional generative adversarial networks. International Journal of Green Energy, 2024, 21: 2653. DOI: 10.1080/15435075.2024.2322976.

[36] Mifsud M., Vendl A., Hansen L., et al., Fusing wind-tunnel measurements and CFD data using constrained gappy proper orthogonal decomposition. Aerospace Science and Technology, 2019, 86: 312–326. DOI: 10.1016/j.ast.2018.12.036.

[37] Everson R., Sirovich L., Karhunen-Loève procedure for gappy data. Journal of the Optical Society of America, A, Optics, Image Science, and Vision, 1995, 12(8): 1657. DOI: 10.1364/JOSAA.12.001657.

[38] Lei J., Liu S., Temperature field reconstruction from the partial measurement data using the gappy proper orthogonal decomposition. IET Science, Measurement & Technology, 2013, 7(3): 171–179. DOI: 10.1049/iet-smt.2012.0155.

[39] Jiang G., Kang M., Cai Z., et al., Online reconstruction of 3D temperature field fused with POD-based reduced order approach and sparse sensor data. International Journal of Thermal Sciences, 2022, 175: 107489. DOI: 10.1016/j.ijthermalsci.2022.107489.

[40] Park J., Lee W., Huh K.Y., Model order reduction by radial basis function network for sparse reconstruction of an industrial natural gas boiler. Case Studies in Thermal Engineering, 2022, 37: 102288. DOI: 10.1016/j.csite.2022.102288.

[41] Jo T., Koo B., Kim H., et al., Effective sensor placement in a steam reformer using gappy proper orthogonal decomposition. Applied Thermal Engineering, 2019, 154: 419–432. DOI: 10.1016/j.applthermaleng.2019.03.089.

[42] Xing X., Dao M.H., Zhang B., et al., Fusing sensor data with CFD results using gappy POD. Ocean Engineering, 2022, 246: 110549. DOI: 10.1016/j.oceaneng.2022.110549.

[43] Yildirim B., Chryssostomidis C., Karniadakis G.E., Efficient sensor placement for ocean measurements using low-dimensional concepts. Ocean Modelling, 2009, 27(3): 160–173. DOI: 10.1016/j.ocemod.2009.01.001.

[44] Willcox K., Unsteady flow sensing and estimation via the gappy proper orthogonal decomposition. Computers & Fluids, 2006, 35(2): 208–226. DOI: 10.1016/j.compfluid.2004.11.006.

[45] Wang S., Zhang Y., Li H., et al., Thermohydrodynamic analysis of the vertical gas wall and reheat gas wall in a 300 MW supercritical CO2 boiler. Energy, 2020, 211: 118611. DOI: 10.1016/j.energy.2020.118611.

[46] Yang Y., Bai W., Wang Y., et al., Coupled simulation of the combustion and fluid heating of a 300 MW supercritical CO2 boiler. Applied Thermal Engineering, 2017, 113: 259–267. DOI: 10.1016/j.applthermaleng.2016.11.043.

[47] Yan J., Jin D., Liu X., et al., A coupled combustion and hydrodynamic model for the prediction of waterwall tube overheating of supercritical boiler. Fuel, 2023, 334: 126589. DOI: 10.1016/j.fuel.2022.126589.

[48] Yang D.L., Tang G.H., Fan Y.H., et al., Arrangement and three-dimensional analysis of cooling wall in 1000 MW SCO2 coal-fired boiler. Energy, 2020, 197: 117168. DOI: 10.1016/j.energy.2020.117168.

[49] Jin D., Yan J., Liu X., et al., Prediction of tube temperature distribution of boiler platen superheater by a coupled combustion and hydrodynamic model. Energy, 2023, 279: 128116. DOI: 10.1016/j.energy.2023.128116.

[50] He X., Yu Y., Xie Z., et al., A modified CFD-DEM method for accurate prediction of the minimum fluidization velocity. International Journal of Fluid Engineering, 2024, 1(2): 23902. DOI: 10.1063/5.0200589.

[51] Jin Y., Kuznetsov A.V., Multiscale modeling and simulation of turbulent flows in porous media. International Journal of Fluid Engineering, 2024, 1(1): 3576. DOI: 10.1063/5.0190279.

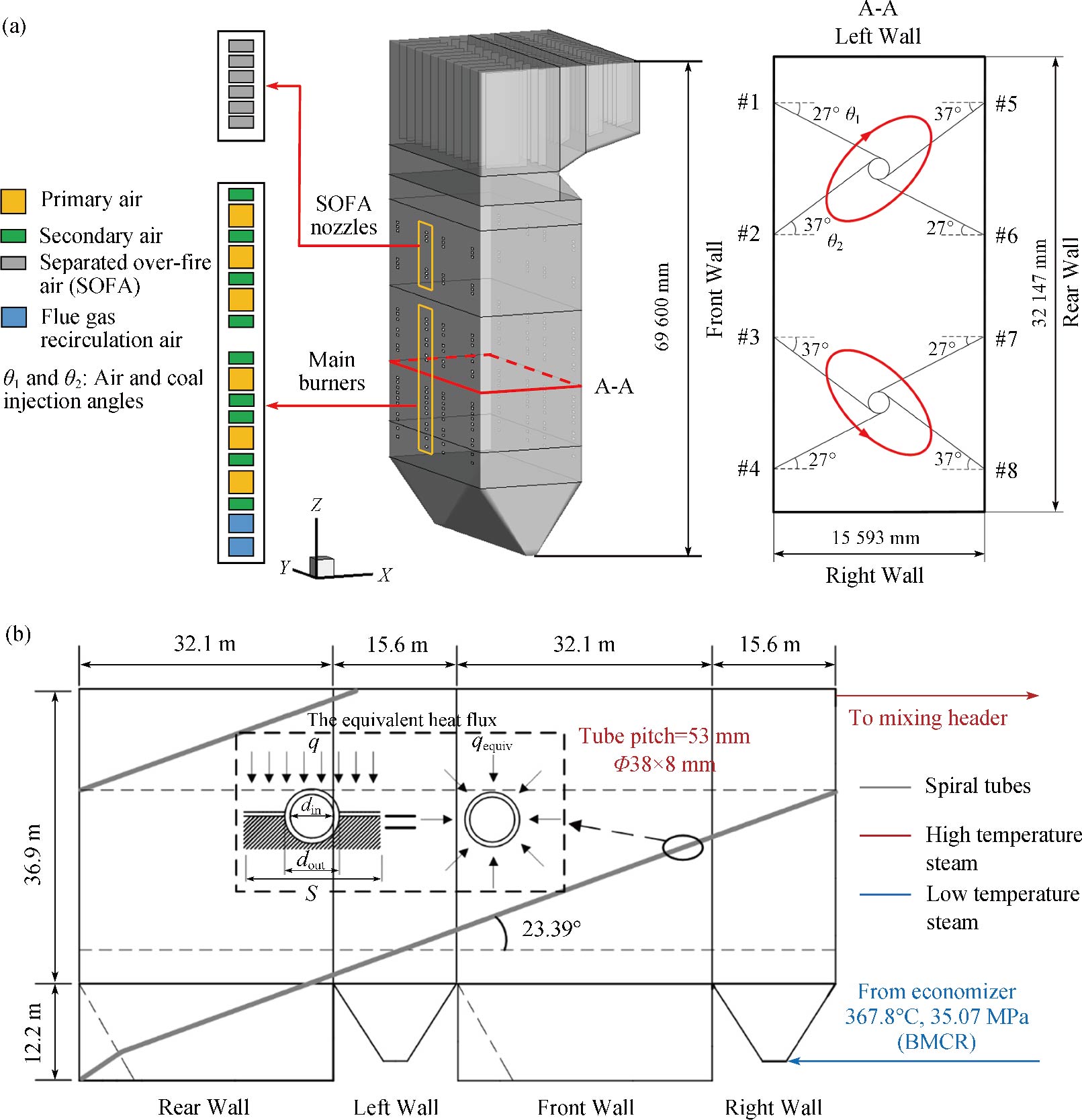

[52] Pan Z., Chen X., Zhong W., et al., Research on numerical simulation of dual tangential firing boiler based on coupling combustion and hydrodynamic for thermal deviation. Proceedings of the Chinese Society of Electrical Engineering, 2023, 43(22): 1–13. DOI: 10.13334/j.0258-8013.pcsee.230489.

[53] Qin L., Liu S., Long T., et al., Wind field reconstruction using dimension-reduction of CFD data with experimental validation. Energy, 2018, 151: 272–288. DOI: 10.1016/j.energy.2018.02.141.

[54] Bui-Thanh T., Damodaran M., Willcox K., Aerodynamic data reconstruction and inverse design using proper orthogonal decomposition. AIAA Journal, 2004, 42(8): 1505–1516. DOI: 10.2514/1.2159.

[55] Koo B., Jo T., Lee D., Modified inferential POD/ML for data-driven inverse procedure of steam reformer for 5-kW HT-PEMFC. Computers & Chemical Engineering, 2019, 121: 375–387. DOI: 10.1016/j.compchemeng.2018.11.012.

[56] Koo B., Jo T., Shin E., et al., Reduced-order model with radial basis function network for leak detection. Journal of hydraulic research, 2019, 57(3): 426–438. DOI: 10.1080/00221686.2018.1494051.

[57] Guénot M., Lepot I., Sainvitu C., et al., Adaptive sampling strategies for non-intrusive POD-based surrogates. Engineering Computations, 2013, 30(4): 521–547. DOI: 10.1108/02644401311329352.

[58] Yeh S., Wang X., Sung C., et al., Common proper orthogonal Decomposition-Based spatiotemporal emulator for design exploration. AIAA Journal, 2018, 56(6): 2429–2442. DOI: 10.2514/1.J056640.