[1] Wang W., Li W., Lu Y., et al., Modification of melting combustion kinetic model of fine ash from entrained-flow gasifier. Journal of Thermal Science, 2024, 33(1): 300–310. DOI: 10.1007/s11630-023-1877-9.

[2] Chang S., Zhuo J., Meng S., et al., Clean coal technologies in China: Current status and future perspectives. Engineering, 2016, 2(4): 447–459.

DOI: 10.1016/j.Eng.2016.04.015.

[3] Zhou L, Ren Q., Yang G., et al., Flow properties of entrained flow gasifier fine slag and network structure of its molten slag. Journal of Thermal Science, 2023, 32(5): 1878–1888. DOI: 10.1007/s11630-023-1874-z.

[4] Wang Y., Guo C.-H., Du C., et al., Carbon peak and carbon neutrality in China: Goals, implementation path, and prospects. China Geology, 2021, 4: 1–27.

DOI: 10.31035/cg2021083.

[5] Zhu S., Hui J., Lyu Q., et al., Experimental study on pulverized coal combustion preheated by a circulating fluidized bed: Preheating characteristics for peak shaving. Fuel, 2022, 324: 124684.

DOI: 10.1016/j.fuel.2022.124684.

[6] Fu J., Tang C., Jin W., et al., Study on laminar flame speed and flame structure of syngas with varied compositions using OH-PLIF and spectrograph. International Journal of Hydrogen Energy, 2013, 38(3): 1636–1643. DOI: 10.1016/j.ijhydene.2012.11.023.

[7] Wang J., Huang Z., Kobayashi H., et al., Laminar burning velocities and flame characteristics of CO-H2-CO2-O2 mixtures. International Journal of Hydrogen Energy, 2012, 37(24): 19158–19167.

DOI: 10.1016/j.ijhydene.2012.07.103.

[8] Wang Z.H., Weng W.B., He Y., et al., Effect of H2/CO ratio and N2/CO2 dilution rate on laminar burning velocity of syngas investigated by direct measurement and simulation. Fuel, 2015, 141: 285–292.

DOI: 10.1016/j.fuel.2014.10.040.

[9] Dong C., Zhou Q., Zhao Q., et al., Experimental study on the laminar flame speed of hydrogen/carbon monoxide/air mixtures. Fuel, 2009, 88(10): 1858–1863.

DOI: 10.1016/j.fuel.2009.04.024.

[10] Zhou S., Yang W., Tan H., et al., Experimental and kinetic modeling study on NH3/syngas/air and NH3/bio-syngas/air premixed laminar flames at elevated temperature. Combustion and Flame, 2021, 233: 111594.

DOI: 10.1016/j.combustflame.2021.111594.

[11] Wang J., Zhang M., Xie Y., et al., Correlation of turbulent burning velocity for syngas/air mixtures at high pressure up to 1.0 MPa. Experimental Thermal and Fluid Science, 2013, 50: 90–96.

DOI: 10.1016/j.expthermflusci.2013.05.008.

[12] Zhang M., Wang J., Wu J., et al., Flame front structure of turbulent premixed flames of syngas oxyfuel mixtures. International Journal of Hydrogen Energy, 2014, 39(10): 5176–5185. DOI: 10.1016/j.ijhydene.2014.01.038.

[13] Zhao H., Wang J., Cai X., et al., Flame structure, turbulent burning velocity and its unified scaling for lean syngas/air turbulent expanding flames. International Journal of Hydrogen Energy, 2021, 46(50): 25699–25711. DOI: 10.1016/j.ijhydene.2021.05.090.

[14] Molcan P., Lu G., Bris T.L., et al., Characterisation of biomass and coal co-firing on a 3 MWth Combustion Test Facility using flame imaging and gas/ash sampling techniques. Fuel, 2009, 88(12): 2328–2334.

DOI: 10.1016/j.fuel.2009.06.027.

[15] Smart J., Lu G., Yan Y., et al., Characterisation of an oxy-coal flame through digital imaging. Combustion and Flame, 2010, 157(6): 1132–1139.

DOI: 10.1016/j.combustflame.2009.10.017.

[16] Zhang J., Kelly K.E., Eddings E.G., et al., Ignition in 40 kW co-axial turbulent diffusion oxy-coal jet flames. Proceedings of the Combustion Institute, 2011, 33(2): 3375–3382. DOI: 10.1016/j.proci.2010.06.106.

[17] Molina A., Shaddix C.R., Ignition and devolatilization of pulverized bituminous coal particles during oxygen/carbon dioxide coal combustion. Proceedings of the Combustion Institute, 2007, 31(2): 1905–1912.

DOI: 10.1016/j.proci.2006.08.102.

[18] Shaddix C.R., Molina A., Particle imaging of ignition and devolatilization of pulverized coal during oxy-fuel combustion. Proceedings of the Combustion Institute, 2009, 32(2): 2091–2098.

DOI: 10.1016/j.proci.2008.06.157.

[19] Liu Y., Geier M., Molina A., et al., Pulverized coal stream ignition delay under conventional and oxy-fuel combustion conditions. International Journal of Greenhouse Gas Control, 2011, 5: S36–S46.

DOI: 10.1016/j.ijggc.2011.05.028.

[20] Zhou K., Lin Q., Hu H., et al., The ignition characteristics and combustion processes of the single coal slime particle under different hot-coflow conditions in N2/O2 atmosphere. Energy, 2017, 136: 173–184.

DOI: 10.1016/j.energy.2016.02.038.

[21] Zhou K., Lin Q., Hu H., et al., Ignition and combustion behaviors of single coal slime particles in CO2/O2 atmosphere. Combustion and Flame, 2018, 194: 250–263. DOI: 10.1016/j.combustflame.2018.05.004.

[22] Levendis Y.A., Joshi K., Khatami R., et al., Combustion behavior in air of single particles from three different coal ranks and from sugarcane bagasse. Combustion and Flame, 2011, 158(3): 452–465.

DOI: 10.1016/j.combustflame.2010.09.007.

[23] Khatami R., Stivers C., Joshi K., et al., Combustion behavior of single particles from three different coal ranks and from sugar cane bagasse in O2/N2 and O2/CO2 atmospheres. Combustion and Flame, 2012, 159(3): 1253–1271. DOI: 10.1016/j.combustflame.2011.09.009.

[24] Riaza J., Khatami R., Levendis Y.A., et al., Single particle ignition and combustion of anthracite, semi-anthracite and bituminous coals in air and simulated oxy-fuel conditions. Combustion and Flame, 2014, 161(4): 1096–1108.

DOI: 10.1016/j.combustflame.2013.10.004.

[25] Bai X., Lu G., Bennet T., et al., Measurement of coal particle combustion behaviors in a drop tube furnace through high-speed imaging and image processing. 2016 IEEE International Instrumentation and Measurement Technology Conference Proceedings, 2016. http://doi.org/10.1109/i2mtc.2016.7520582.

[26] Xu K., Wu Y., Wang Z., et al., Experimental study on ignition behavior of pulverized coal particle clouds in a turbulent jet. Fuel, 2016, 167: 218–225.

DOI: 10.1016/j.fuel.2015.11.027.

[27] Balusamy S., Schmidt A., Hochgreb S., Flow field measurements of pulverized coal combustion using optical diagnostic techniques. Experiments in Fluids, 2013, 54(5): 1534. DOI: 10.1007/s00348-013-1534-2.

[28] Balusamy S., Kamal M.M., Lowe S.M., et al., Laser diagnostics of pulverized coal combustion in O2/N2 and O2/CO2 conditions: velocity and scalar field measurements. Experiments in Fluids, 2015, 56(5): 108. DOI: 10.1007/s00348-015-1965-z.

[29] Hwang S.M., Kurose R., Akamatsu F., et al., Application of optical diagnostics techniques to a laboratory-scale turbulent pulverized coal flame. Energy & Fuels, 2005, 19(2): 382–392.

[30] Hwang S.-M., Kurose R., Akamatsu F., et al., Observation of detailed structure of turbulent pulverized-coal flame by optical measurement (part 1, time-averaged measurement of behavior of pulverized-coal particles and flame structure). JSME International Journal Series B Fluids and Thermal Engineering, 2006, 49(4): 1316–1327.

DOI: 10.1299/jsmeb.49.1316.

[31] Hwang S.-M., Kurose R., Akamatsu F., et al., Observation of detailed structure of turbulent pulverized-coal flame by optical measurement (Part 2, instantaneous two-dimensional measurement of combustion reaction zone and pulverized-coal particles. JSME International Journal Series B Fluids and Thermal Engineering, 2006, 49(4): 1328–1335.

DOI: 10.1299/jsmeb.49.1328.

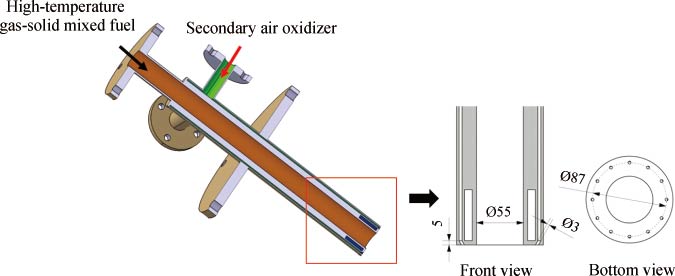

[32] Lu Y., Fang N., Zhang B., et al., Effect of air distribution mode on jet flame and emission characteristics of high temperature gas-solid mixed fuel. Journal of the Energy Institute, 2024, 116:101741.

[33] González-Cencerrado A., Peña B., Gil A., Coal flame characterization by means of digital image processing in a semi-industrial scale PF swirl burner. Applied Energy, 2012, 94: 375–384.

DOI: 10.1016/j.apenergy.2012.01.059.

[34] Zhu S., Zhu J., Lyu Q., et al., NO emissions under pulverized char combustion in O2/CO2/H2O preheated by a circulating fluidized bed. Fuel, 2019, 252: 512–521.

DOI: 10.1016/j.fuel.2019.04.153.

[35] Fan P., Gong Y., Zhang Q., et al., Experimental study of the impinging flame height in an opposed multi-burner gasifier. Energy & Fuels, 2014, 28(8): 4895–4904. http://doi.org/10.1021/ef5007287.

[36] Zhao C., Li X., Wang X., et al., An experimental study of the characteristics of blended hydrogen-methane non-premixed jet flames. Process Safety and Environmental Protection, 2023, 174: 838–847.

DOI: 10.1016/j.psep.2023.04.041.

[37] Matsui Y., Kamimoto T., Matsuoka S., A study on the time and space resolved measurement of flame temperature and soot concentration in a D. I. diesel engine by the two-color method. 1979 Automotive Engineering Congress and Exposition, 1979.

DOI: 10.4271/790491.

[38] Shao L., Zhou Z., Chen L., et al., Study of an improved two-colour method integrated with the emissivity ratio model and its application to air- and oxy-fuel flames in industrial furnaces. Measurement, 2018, 123: 54–61.

DOI: 10.1016/j.measurement.2018.03.024.

[39] Xu W., Yan Y., Huang X., et al., Quantitative measurement of the stability of a pulverized coal fired flame through digital image processing and statistical analysis. Measurement, 2023, 206: 112328.

DOI: 10.1016/j.measurement.2022.112328.

[40] Chen Z.B., Hu L.H., Huo R., et al., Flame oscillation frequency based on image Correlation. Journal of Combustion Science and Technology, 2008, 14(4): 367–371. (in Chinese)

DOI: 10.3321/j.issn:1006-8740.2008.04.015.

[41] Yan Y., Lu G., Colechin M.J.F., Monitoring and characterisation of pulverised coal flames using digital imaging techniques. Fuel, 2002, 81(5): 647–655.

DOI: 10.1016/S0016-2361(01)00161-2.

[42] Lu G., Yan Y., Colechin M., A digital imaging based multifunctional flame monitoring system. IEEE Transactions on Instrumentation and Measurement, 2004, 53(4): 1152–1158. DOI: 10.1109/tim.2004.830571.

[43] Zhang J., Kelly K.E., Eddings E.G., et al., CO2 effects on near field aerodynamic phenomena in 40 kW, co-axial, oxy-coal, turbulent diffusion flames. International Journal of Greenhouse Gas Control, 2011, 5: S47–S57.

DOI: 10.1016/j.ijggc.2011.05.022.

[44] Obando J., Lezcano C., Amell A., Experimental analysis of the addition and substitution of sub-bituminous pulverized coal in a natural gas premixed flame. Applied Thermal Engineering, 2017, 125: 232–239.

DOI: 10.1016/j.applthermaleng.2017.07.003.

[45] Ma P., Huang Q., Wu Z., et al., Optical diagnostics on coal ignition and gas-phase combustion in co-firing ammonia with pulverized coal on a two-stage flat flame burner. Proceedings of the Combustion Institute, 2023, 39(3): 3457–3466.

DOI: 10.1016/j.proci.2022.07.221.

[46] Tao C., Liu B., Dou Y., et al., The experimental study of flame height and lift-off height of propane diffusion flames diluted by carbon dioxide. Fuel, 2021, 290: 119958. DOI: 10.1016/j.fuel.2020.119958.

[47] Hottel H., Hawthorne W., Diffusion in laminar flame jets. Symposium on Combustion and Flame, and Explosion Phenomena. 3. Elsevier, 1948, pp: 254–266.

[48] Kang Y.-H., Wang Q.-H., Lu X.-F., et al., Experimental and theoretical study on the flow, mixing, and combustion characteristics of dimethyl ether, methane, and LPG jet diffusion flames. Fuel processing technology, 2015, 129: 98–112.

DOI: 10.1016/j.fuproc.2014.09.004.

[49] Bragg G.M., Bednarik H.V., et al., Particulate diffusion across a plane turbulent jet. International Journal of Heat and Mass Transfer, 1975, 18(3): 443–451.

DOI: 10.1016/0017-9310(75)90032-0.

[50] Sahu K., Kundu A., Ganguly R., et al., Effects of fuel type and equivalence ratios on the flickering of triple flames. Combustion and Flame, 2009, 156(2): 484–493. DOI: 10.1016/j.combustflame.2008.11.017.

[51] Lu G., Yan Y., Huang Y., et al., An intelligent vision system for monitoring and control of combustion flames. Measurement and Control, 1999, 32(7): 164–168.

DOI: 10.1177/002029409903200601.

[52] Li J., Zhang Y., Fuel variability effect on flickering frequency of diffusion flames. Frontiers of Energy and Power Engineering in China, 2009, 3(2): 134–140.

DOI: 10.1007/s11708-009-0034-9.

[53] Kim J.H., Kim S.G., Lee K.M., et al., An experimental study on thermoacoustic instabilities in syngas-air premixed impinging jet flames. Fuel, 2019, 257: 115921.

DOI: 10.1016/j.fuel.2019.115921.

[54] Peng J., Cao Z., Yu X., et al., Oscillation characterization of volatile combustion of single coal particles with multi-species optical diagnostic techniques. Fuel, 2020, 282: 118845. DOI: 10.1016/j.fuel.2020.118845.

[55] Lu G., Yan Y., Colechin M., et al., Monitoring of oscillatory characteristics of pulverized coal flames through image processing and spectral analysis. IEEE Transactions on Instrumentation and Measurement, 2006, 55(1): 226–231. DOI: 10.1109/tim.2005.861254.