[1] Chowdhury T.S., Mohsin F.T., Tonni M.M., Mita M.N.H., Ehsan M.M., A critical review on gas turbine cooling performance and failure analysis of turbine blades. International Journal of Thermofluids, 2023, 18: 100329.

DOI: 10.1016/j.ijft.2023.100329.

[2] Goldstein R.J., Film cooling. Advances in Heat Transfer, 1971, 7: 321–379.

DOI: 10.1016/S0065-2717(08)70020-0.

[3] Goldstein R., Eckert E., Burggraf F., Effects of hole geometry and density on three-dimensional film cooling. International Journal of Heat and Mass Transfer, 1974, 17(5): 595–607. DOI: 10.1016/0017-9310(74)90007-6.

[4] Gritsch M., Schulz A., Wittig S., Film-cooling holes with expanded exits: near-hole heat transfer coefficients. International Journal of Heat and Fluid Flow, 2000, 21(2): 146–155. DOI: 10.1016/S0142-727X(99)00076-4.

[5] Gritsch M., Colban W., Schär H., Döbbeling K., Effect of hole geometry on the thermal performance of fan-shaped film cooling holes. Journal of Turbomachinery, 2005, 127(4): 718–725. DOI: 10.1115/1.2019315.

[6] Colban W.F., Thole K.A., Bogard D., A film-cooling correlation for shaped holes on a flat-plate surface. Journal of Turbomachinery, 2011, 133(1): 011002.

DOI: 10.1115/1.4002064.

[7] Schroeder R.P., Thole K.A., Adiabatic effectiveness measurements for a baseline shaped film cooling hole. Turbo Expo: Power for Land, Sea, and Air, 2014, 5B: V05BT13A036. DOI: 10.1115/GT2014-25992.

[8] Fraas M., Glasenapp T., Schulz A., Bauer H.-J., Film cooling measurements for a laidback fan-shaped hole: effect of coolant crossflow on cooling effectiveness and heat transfer. Journal of Turbomachinery, 2019, 141(4): 041006. DOI: 10.1115/1.4041655.

[9] Dorrington J.R., Bogard D.G., Bunker R.S., Film effectiveness performance for coolant holes imbedded in various shallow trench and crater depressions. Turbo Expo: Power for Land, Sea, and Air, 2007, 4: 749–758.

DOI: 10.1115/GT2007-27992.

[10] Song Y.J., Park S.H., Kang Y.J., Kwak J.S., Effects of trench configuration on the film cooling effectiveness of a fan-shaped hole. International Journal of Heat and Mass Transfer, 2021, 178: 121655.

DOI: 10.1016/j.ijheatmasstransfer.2021.121655.

[11] Sakai E., Takahashi T., Agata Y., Experimental study on effects of internal ribs and rear bumps on film cooling effectiveness. Journal of Turbomachinery, 2013, 135(3): 031025. DOI: 10.1115/1.4007546.

[12] Benabed M., Computational optimization of Coanda effect on film-cooling performance. Journal of Thermophysics and Heat Transfer, 2015, 29(4): 757–765.

DOI: 10.2514/1.T4487.

[13] Na S., Shih T.I., Increasing adiabatic film-cooling effectiveness by using an upstream ram. Journal of Heat and Mass Transfer, 2007, 129(4): 464–471.

DOI: 10.1115/1.2709965.

[14] Veley E.M., Thole K.A., Cooling performance of film-cooling holes fed by channels of various shapes. International Journal of Heat and Mass Transfer, 2023, 216(1): 124561.

DOI: 10.1016/j.ijheatmasstransfer.2023.124561.

[15] Kim J.-H., Kim K.-Y., Film-cooling performance of converged-inlet hole shapes. International Journal of Thermal Sciences, 2018, 124: 196–211.

DOI: 10.1016/j.ijthermalsci.2017.10.014.

[16] Kim J.-H., Kim K.-Y., Performance evaluation of a converging-diverging film-cooling hole. International Journal of Thermal Sciences, 2019, 142: 295–304.

DOI: 10.1016/j.ijthermalsci.2019.04.027.

[17] Fraas M., Glasenapp T., Schulz A., Bauer H.-J., Optimized inlet geometry of a laidback fan-shaped film cooling hole—Experimental study of film cooling performance. International Journal of Heat and Mass Transfer, 2019, 128: 980–990.

DOI: 10.1016/j.ijheatmasstransfer.2018.09.035.

[18] Kim J.-H., Kang C., A novel design for film-cooling: Cooling holes with inlet groove. International Journal of Thermal Sciences, 2024, 195: 108649.

DOI: 10.1016/j.ijthermalsci.2023.108649.

[19] Leylek J., Zerkle R., Discrete-jet film cooling: a comparison of computational results with experiments. Journal of Turbomachinery, 1994, 116(3): 358–368.

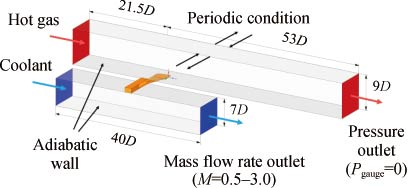

DOI: 10.1115/1.2929422

[20] Seo H., Lee J., Ligrani P., Effects of bulk flow pulsations on film cooling from different length injection holes at different blowing ratios. Journal of Turbomachinery, 1999, 121(3): 542–550. DOI: 10.1115/1.2841349.

[21] Lutum E., Johnson B.V., Influence of the hole length-to-diameter ratio on film cooling with cylindrical holes. Journal of Turbomachinery, 1999, 121(2): 209–216. DOI: 10.1115/1.2841303.

[22] Li W., Lu X., Li X., Ren J., Jiang H., High resolution measurements of film cooling performance of simple and compound angle cylindrical holes with varying hole length-to-diameter ratio—Part I: Adiabatic film effectiveness. International Journal of Thermal Sciences, 2018, 124: 146–161.

DOI: 10.1016/j.ijthermalsci.2017.10.013.

[23] Kohli A., Thole K.A., Entrance effects on diffused film-cooling holes. International Gas Turbine and Aeroengine Congress and Exhibition, 1998, 4: V004T09A070. DOI: 10.1115/98-GT-402.

[24] Jo Y.R., Kim Y.S., Kang M.S., Jeong J.Y., Kim H.J., Kwak J.S., Experimental and numerical investigation on the metering and diffuser length effects of a laidback fan-shaped film cooling hole. Thermal Science and Engineering Progress, 2023, 46(1): 102232.

DOI: 10.1016/j.tsep.2023.102232.

[25] Huang X., Pu J., Zhang T., Wang J.-H., Wu W.-L., Wu X.-Y., Effect of length-to-diameter ratio on film cooling and heat transfer performances of simple and compound cylindrical-holes in transverse trenches with various depths. International Journal of Heat and Mass Transfer, 2022, 185: 122328.

DOI: 10.1016/j.ijheatmasstransfer.2021.122328.

[26] Shih T.-H., Liou W.W., Shabbir A., Yang Z., Zhu J., A new k-ϵ eddy viscosity model for high Reynolds number turbulent flows. Computers & Fluids, 1995, 24(3): 227–238. DOI: 10.1016/0045-7930(94)00032-T.

[27] Sutherland W., LII., The viscosity of gases and molecular force. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1893, 36(223): 507–531. DOI: 10.1080/14786449308620508.

[28] Liu C.-L., Zhu H.-R., Bai J.-T., Effect of turbulent Prandtl number on the computation of film-cooling effectiveness. International Journal of Heat and Mass Transfer, 2008, 51(25): 6208–6218.

DOI: 10.1016/j.ijheatmasstransfer.2008.04.039.

[29] Fluent A., Ansys fluent theory guide. Ansys Inc., USA, 2011, 15317: 724–746.

[30] Saumweber C., Schulz A., Free-stream effects on the cooling performance of cylindrical and fan-shaped cooling holes. Journal of Turbomach, 2012, 134(6): 061007. DOI: 10.1115/1.4006287.

[31] Chen Z., Zhang Z., Li Y., Su X., Yuan X., Vortex dynamics based analysis of internal crossflow effect on film cooling performance. International Journal of Heat and Mass Transfer, 2019, 145: 118757.

DOI: 10.1016/j.ijheatmasstransfer.2019.118757.