[1] Tan L., Xiao H., Yu K., et al., A blockchain-empowered crowdsourcing system for 5G-enabled smart cities. Computer Standards & Interfaces, 2021, 76: 103517.

[2] Stark A.E., Thermal contact resistance measurement and related uncertainties. Old Dominion University, Norfolk, United State of America, 2020.

[3] Cooper M.G., Mikic B.B., Yovanovich M.M., Thermal contact conductance. International Journal of Heat and Mass Transfer, 1969, 12: 279–300.

[4] Bejan A., Kraus A.D., Heat transfer handbook. John Wiley & Sons, New York, 2003, pp: 261–395.

[5] Lambert M.A., Fletcher L.S., Thermal contact conductance of spherical rough metals. Journal of Heat Transfer, 1997, 119: 684–690.

[6] Bahrami M., Culham J.R., Yovanovich M.M., et al., Thermal contact resistance of nonconforming rough surfaces, part 2, thermal model. Journal of Thermophys and Heat Transfer, 2004, 18: 218–227.

[7] Hao G., Liu Z., The heat partition into cutting tool at tool-chip contact interface during cutting process: a review. The International Journal of Advanced Manufacturing Technology, 2020, 108: 393–411.

[8] Hao G., Liu Z., Experimental study on the formation of TCR and thermal behavior of hard machining using TiAlN coated tools. International Journal of Heat and Mass Transfer, 2019, 140: 1–11.

[9] Wang J. X., Guo W., Xiong K., et al., Review of aerospace-oriented spray cooling technology. Progress in Aerospace Sciences, 2020, 116: 100635.

[10] Wang J.X., Li Y.Z., Yu X.K., et al., Investigation of heat transfer mechanism of low environmental pressure large-space spray cooling fornear-space flight systems. International Journal of Heat and Mass Transfer, 2018, 119: 496–507.

[11] Kasimalla V.K., Velisala V., A review on energy allocation of fuel cell/battery/ultracapacitorfor hybrid electric vehicles. International Journal of Energy Research, 2018, 42: 4263–4283.

[12] Grabon W., Pawlus P., Wos S., et al., Effects of cylinder liner surface topography on friction and wear of liner-ring system atlow temperature. Tribology International, 2018, 121: 148–160.

[13] Saleem S.S., Wani M.F., Effect of load on tribofilms at the contact interface under dry sliding conditions at 500°C. Materials Science & Engineering Technology, 2018, 49: 169–184.

[14] Dai S., Wang D., Zhang H., et al., Thermal contact resistance between aero engine compressor blade and flexible fixture. Journal of Thermal Science, 2021, 30: 530–539.

[15] Kapitza P.L., The study of heat transfer in helium II. Journal of Physicals (Moscow), 1941, 4: 181.

[16] Xing L., Zhang L.W., Zhang X.Z., et al., Experimental investigation of contact heat transfer at high temperature based on steady-state heatflux method. Experimental Heat transfer, 2010, 23: 107–116.

[17] Burghold E.M., Frekers Y., Kneer R., Determination of time-dependent thermal contact conductance through IR-thermography. International Journal of Thermal Sciences, 2015, 98: 148–155.

[18] Wang J., Zhang Z., Shi R., et al., Impact of nano-scale roughness on heat transport across the solid-solid interface. Advance Materials Interfaces, 2020, 7: 1901582.

[19] Standard test method for thermal transmission properties of thermally conductive electrical insulation materials. West Conshohocken, America, 2006.

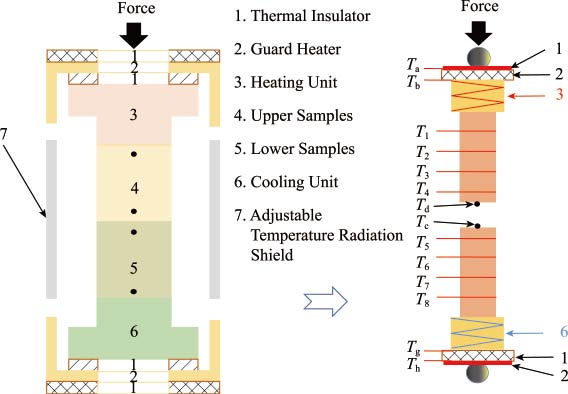

[20] Zhang P., Xuan Y.M., Li Q., A high-precision instrumentation of measuring thermal contact resistance using reversible heat flux. Experimental Thermal and Fluid Science, 2014, 54: 204–211.

[21] Zhang P., Shi B., Xuan Y.M., et al., A high-precision method to measure thermal conductivity of solids using reversible heat-flux. Measurement Science and Technology, 2013, 24: 095004.

[22] Tseng C., Yamaguchi M., Ohmori T., Thermal conductivity of polyurethane foams from room temperature to 20 K. Cryogenics, 1997, 37: 305–312.

[23] Marand H., Xu J., Srinivas S., Determination of the equilibrium melting temperature of polymer crystals: linear and nonlinear Hoffman-Weeks extrapolations. Macromolecules, 1998, 31(23): 8219–8229.

[24] Sun F., Zhang P., Wang H., et al., Experimental study of thermal contact resistance between aluminium alloy and ADP crystal under vacuum environment. Applied Thermal Engineering, 2019, 155: 563–574.

[25] Ren X.J., Ding H., Dai Y.J., et al., Experimental study on thermal contact resistance of carbon fiber reinforced silicon carbide composite with 3D needled preform (3DN C/SiC). International Communications in Heat and Mass Transfer, 2021, 124: 105271.

[26] Chen M., Li Q., Zhang P., Experimental investigation of high temperature thermal contact resistance of thin disk samples using infrared camera in vacuum condition. International Journal of Heat and Mass Transfer, 2020, 157: 119749.

[27] Cui T., Li Q., Xuan Y., et al., Preparation and thermal properties of the graphene-polyolefin adhesive composites: application in thermal interface materials. Microelectronics Reliability, 2015, 55: 2569–2574.

[28] Kwon B., Baek S.H., Keun K.S., et al., Impact of parasitic thermal effects on thermoelectric property measurements by Harman method. Review of Scientific Instruments, 2014, 85: 045108.

[29] Feng B., Tu J., Zhang Y.H., et al., An improved steady-state method for measuring the thermal contact resistance and bulk thermal conductivity of thin-walled materials having a sub-millimeter thickness. Applied Thermal Engineering, 2020, 171: 114931.

[30] Xuan Y.M., Zhang P., Li Q., et al., Method for measuring heat conduction coefficient by using positive and negative bidirectional heat flow method. China Patent, 102778476A, 2012-11-14.

[31] Xuan Y.M., Zhang P., Li Q., et al., Testing method for testing solid-solid contact thermal resistance by using forward and reverse bidirectional heat flux method. China Patent, 102768224A, 2012-11-07.

[32] Zhu Z., Zhang L.W., Wu Q.K., et al., An experimental investigation of thermal contact conductance of Hastelloy C-276 based on steady-state heat flux method. International Communications in Heat and Mass Transfer, 2013, 41: 63–67.

[33] Wang Z.R., Yang J., Wang S., et al., Compensation heating technique for experimental investigation of thermal contact conductance across GH4169/K417 interface. Rare Metal Materials and Engineering, 2013, 42: 1572–1575.

[34] Asif M., Tariq A., Correlations of thermal contact conductance for nominally flat metallic contact in vacuum. Experimental Heat transfer, 2016, 29: 456–484.

[35] Xian Y., Zhang P., Zhai S., et al., Experimental characterization methods for thermal contact resistance: A review. Applied Thermal Engineering, 2018, 130: 1530–1548.

[36] Fieberg C., Kneer R., Determination of thermal contact resistance from transient temperature measurements. International Journal of Heat and Mass Transfer, 2008, 51(5–6): 1017–1023.

[37] Joneidi A.A., Ganji D.D., Babaelahi M., Differential transformation method to determine fin efficiency of convective straight fins with temperature dependent thermal conductivity. International Communications in Heat and Mass Transfer, 2009, 36: 757–762.

[38] Liu J., The experimental research on measurement of thermal contact resistance of two contacted solids and thermal conductivity. Huazhong University of Science and Technology, Wuhan, China, 2011.

[39] Chen J., Zhang W., Feng Z., et al., Determination of thermal contact conductance between thin metal sheets of battery tabs. International Journal of Heat and Mass Transfer, 2014, 69: 473–480.

[40] Yovanovich M.M., Four decades of research on thermal contact, gap, and joint resistance in microelectronics. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2005, 28: 182–206.

[41] Khuu V., Osterman M., Bar C.A., et al., Thermal performance measurements of thermal interface materials using the laserflash method. International Electronic Packaging Technical Conference and Exhibition, Vancouver, British Columbia, CANADA, 2007, pp: 405–414.

[42] Khuu V., Osterman M.., Bar C.A., et al., Considerations in the use of the laser flash method for thermal measurements of thermal interface materials. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2011, 1: 1015–1028.

[43] Kagata K., Kageyama K., Kinoshita S., et al., Evaluation of thermal contact resistance between two solid surfaces using photoacoustic technique. International Journal of Thermophysics, 2020, 41: 1–17.

[44] Bennett C.A., Patty R.R., Thermal wave interferometry: a potential application of the photoacoustic effect. Applied Optics, 1982, 21: 49–54.

[45] Cola B.A., Xu J., Cheng C., et al., Photoacoustic characterization of carbon nanotube array thermal interfaces. Journal of Applied Physics, 2007, 101: 054313.

[46] Wang X., Cola B.A., Bougher T.L., et al., Photoacoustic technique for thermal conductivity and thermal interface measurements. Annual Review of Heat Transfer, 2013, 16: 135–157.

[47] Schneider D., Schwarz T., A photoacoustic method for characterising thin films. Surface and Coatings Technology, 1997, 91: 136–146.

[48] Richard L., Optical measurement of surface topography. Springer Berlin Heidelberg, Heidelberg, Germany, 2011.

[49] Lee D.H., Cho N.G., Assessment of surface profile data acquired by a stylus profilometer. Measurement Science and Technology, 2012, 23: 105601.

[50] Lee G., Mou J., Shen Y., Sampling strategy design for dimensional measurement of geometric features using coordinate measuring machine. International Journal of Machine Tools and Manufacture, 1997, 37: 917–934.

[51] Hemming B., Ikonen E., Noorma M., Measurement of aperture areas using an optical coordinate measuring machine. International Journal of Optomechatronics, 2007, 1: 297–311.

[52] Feng B., Wang J.H., The optical means used in measuring surface microtopography. Metrology & Measurement Technique, 2005, 6: 4–6.

[53] Bhushan B., Modern tribology handbook, two volume set. CRC Press, Boca Raton, 2000.

[54] Marinello F., Bariani P., Savio E., et al., Critical factors in SEM3D stereo microscopy. Measurement Science and Technology, 2008, 19(6): 065705.

[55] Pennec F., Peyrou D., Leray D., et al., Courtade, impact of the surface roughness description on the electrical contact resistance of ohmic switches under low actuation forces. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2012, 2: 85–94.

[56] Vasilev E., Wang J., Marko K., A structure metric for quantitative assessment of fracture surfaces in 3D conceived based on confocal laser scanning microscopy data. Materials Characterization, 2022, 194: 112369.

[57] Silva R.M., Izquierdo J., Milagre M.X., et al., Electrochemical characterization of alloy segregation in the near-surface deformed layer of welded zones of an Al-Cu-Li alloy using scanning electrochemical microscopy. Electrochimica Acta, 2022, 427: 140873.

[58] Dai, Y.J., Gou J.J., Ren X.J., et al., A test-validated prediction model of thermal contact resistance for Ti-6Al-4V alloy. Applied Energy, 2018, 228: 1601–1617.

[59] Chen Y., Chen L., Chu W., Effect mechanism and performance evaluation of flange contact thermal resistance in an aero-engine. Aerospace, 2022, 9: 121.

[60] Babu K.N., Thermal contact resistance: experiments and simulation. Chalmers University of Technology, Gothenburg, Switzerland, 2015.

[61] Tao W.Q. Heat Transfer. Higer Education Press, fifth ed., Beijing, 2018, pp. 443–479.

[62] Grujicic M., Zhao C.L., Dusel E.C., The effect of thermal contact resistance on heat management in the electronic packaging. Applied Surface Science, 2005, 246: 290–302.

[63] Liang Z., Xu C., Shang H., et al., High thermoelectric energy conversion efficiency of a unicouple of n-type Mg3Bi2 and p-type Bi2Te3. Materials Today Physics, 2021, 19: 100413.

[64] Lambert M.A., Fletcher L.S., Review of models for thermal contact conductance of metals. Journal of Thermophysics and Heat Transfer, 1997, 11: 129–140.

[65] Cooper A.J., Tuck O.C.G., Burnett T.L., et al., A statistical assessment of ductile damage in 304L stainless steel resolved using X-ray computed tomography. Materials Science and Engineering: A, 2018, 728: 218–230.

[66] Bahrami M., Culham J.R., Yananovich M.M., et al., Review of-thermal joint resistance models for nonconforming rough surfaces. Applied Mechanics Reviews, 2006, 59: 1–12.

[67] Williamson J.B., Pullen J., Hunt R.T., et al., The shape of solid surfaces. Surface Mechanics, 1969, pp: 24–35.

[68] Greenwood J.A., Williamson J.B.P., Contact of nominally flat surfaces. Proceedings of the Royal society A, 1966, 295: 300–319.

[69] Stickel D., Wimmer M.A., Fischer A., Analyzing pin-on-ball wear tests by means of the Greenwood-Williamson contact model. Wear, 2013, 301: 4–10.

[70] Cooper M.G., Mikic B.B., Yovanovich M.M., Thermal contact conductance. International Journal of Heat and Mass Transfer, 1969, 12: 279–300.

[71] Francis H.A., Application of spherical indentation mechanics to reversible and irreversible contact between rough surfaces. Wear, 1977, 45: 221–269.

[72] Johnson K.L., Johnson K.L., Contact mechanics. Cambridge, Cambridge university press, Cambridge, 1987.

[73] Persson B.N.J., Sliding friction: physical principles and applications. Springer Science & Business Media Press, Berlin, 2013.

[74] Ma J., Chen G., Ji L., et al., A general methodology to establish the contact force model for complex contacting surfaces. Mechanical Systems and Signal Processing, 2020, 140: 106678.

[75] Bush A.W., Gibson R.D., Thomas T.R., The elastic contact of a rough surface. Wear, 1975, 35: 87–111.

[76] Bush A.W., Gibson R.D., Keogh G.P., Strongly anisotropic rough surfaces. Journal of Lubrication Technology, 1979, 101(1): 15–20.

[77] Johnson K.L., Kendall K., Roberts A.D., Surface energy and the contact of elastic solids. Proceedings of the Royal society A, 1971, 324(1558): 301–313.

[78] Derjaguin B.V., Muller V.M., Toporov Y.P., Effect of contact deformations on the adhesion of particles. Journal of Colloid and Interface Science, 1975, 53(2): 314–326

[79] Chen X.Z., Elliott J.A., On the scaling law of JKR contact model for coarse-grained cohesive particles. Chemical Engineering Science, 2020, 227: 115906.

[80] Violano G., Afferrante L., On DMT methods to calculate adhesion in rough contacts. Tribology International, 2019, 130: 36–42.

[81] Bhushan B., Wyant J., Meiling J., A new three-dimensional non-contact digital optical profiler. Wear, 1988, 122: 301–312.

[82] Mandelbrot B.B., The fractal geometry of nature. Publisher: San Francisco: W.H. Freeman, 1982.

[83] Zou M., Yu B., Cai J., et al., Fractal model for thermal contact conductance. ASME Journal of Heat and Mass Transfer, 2008, 130(10): 101301.

[84] Chen Y.P., Fu P.P., Zhang C.B. et al., Numerical simulation of laminar heat transfer in microchannels with rough surfaces characterized by fractal Cantor structures. International Journal of Heat and Fluid Flow, 2010, 1: 622–629.

[85] Bahrami M., Yovanovich M.M., Culham J.R., Thermal contact resistance at low contact pressure: Effect of elastic deformation. International Journal of Heat and Mass Transfer, 2005, 48: 3284–3293.

[86] Bourouga B., Bardon J.P., Thermal contact resistance at the interface of double tubes assembled by plastic deformation. Experimental Thermal and Fluid Science, 1998, 18: 168–181.

[87] Zhang J., Liu Y., Yan K., et al., A fractal model for predicting thermal contact conductance considering elasto-plastic deformation and base thermal resistances. Journal of Mechanical Science and Technology, 2019, 33: 475–484.

[88] Bowden F.P., Bowden F.P., Tabor D., The friction and lubrication of solids. Oxford University Press, New York, 2001.

[89] Abbott E.J., Firestone F.A., Specifying surface quality: a method based on accurate measurement and comparison. Journal of Mechanical Engineering, 1933, 55: 569–572.

[90] Madhusudana C.V., Thermal contact conductance. Springer Verlag Press, New York, 1996, pp: 9–54.

[91] Ishigaki H., Kawaguchi I., Mizuta S., A simple estimation of the elastic-plastic deformation of contacting asperities. Wear, 1979, 54: 157–164.

[92] Chang W.R., Etsion I., Bogy D.B., An elastic-plastic model for the contact of rough surfaces. Journal of Tribology, 1987, 109: 257–263.

[93] Majumdar A., Bhushan B., Fractal model of elastic-plastic contact between rough surfaces. Journal of Tribology, 1991, 113: 1–11.

[94] Sridhar M.R., Yovanovich M.M., Contact conductance correlations based on Greenwood and Williamson surface model. Engineering, Materials Science, Physics, 1998, 1: 1.

[95] Cooper M.G., Mikic B.B., Yovanovich M.M., Thermal contact conductance. International Journal of Heat and Mass Transfer, 1969, 12: 279–300.

[96] Milanez F.H., Yovanovich M.M., Mantelli M.B.H., Thermal contact conductance at low contact pressures. Journal of Thermophysics and Heat Transfer, 2004, 18(1): 37–44.

[97] Luo X., Feng H., Liu J., et al., An experimental investigation on thermal contact resistance across metal contact interfaces. 12th International Conference on Electronic Packaging Technology and High Density Packaging. Shang Hai, China, 2011, pp: 1–6.

[98] Mikic B.B., Thermal contact conductance; theoretical considerations. International Journal of Heat and Mass Transfer, 1974, 17: 205–214.

[99] Xian Y., Zhang P., Zhai S., et al., Re-estimation of thermal contact resistance considering near-field thermal radiation effect. Applied Thermal Engineering, 2019, 157: 113601.

[100] Yovanovich M.M., Thermal contact correlations. 16th Thermophysics Conference, Palo Alto, American, 1981, Paper No: 81-1164.

[101] Yuan C., Duan B., Li L., et al., An improved model for predicting thermal contact resistance at liquid-solid interface. International Journal of Heat and Mass Transfer, 2015, 80: 398–406.

[102] Liu Y., Meng Q., Yan X., et al., Research on the solution method for thermal contact conductance between circular-arc contact surfaces based on fractal theory. International Journal of Heat and Mass Transfer, 2019, 145: 118740.

[103] Talukder S., Yeo C.D., Hong Y.K., et al., Analytical modeling and simulation of electrical contact resistance for elastic roughelectrode surface contact including frictional temperature rise. AIP Advances, 2022, 12: 025204.

[104] Xu R., Xu L., An experimental investigation of thermal contact conductance of stainless steel at low temperatures. Cryogenics, 2005, 45: 694–704.

[105] Das A.K., Sadhal S.S., Thermal constriction resistance between two solids for random distribution of contacts. Heat and Mass Transfer, 1999, 35: 101–111.

[106] Dai Y.J., Ren X.J., Wang Y., et al., Effect of thermal expansion on thermal contact resistance prediction based on the dual-iterative thermal-mechanical coupling method. International Journal of Heat and Mass Transfer, 2021, 173: 121243.

[107] Deng J., Qian Z.Q., Simplified analysis of thermal contact resistance on arc-slotted fin core. Applied Thermal Engineering, 2017, 125: 26.

[108] Cui T., Li Q., Xuan Y., et al., Multiscale simulation of thermal contact resistance in electronic packaging. International Journal of Thermal Science, 2014, 83: 16–24.

[109] Zhang P., Cui T., Li Q., Effect of surface roughness on thermal contact resistance of aluminium alloy. Applied Thermal Engineering, 2017, 121: 992–998.

[110] Pi W., Liu Z., Li G., et al., 4D simulation of quench behavior in quasi-isotropic superconducting cable of stacked REBCO tapes considering thermal contact resistance. Science and Technology, 2020, 33: 084005.

[111] Feng G., Feng Y.H., Qiu L., et al., Evaluation of thermal performance for bionic porous ceramic phase change material using micro-computed tomography and lattice Boltzmann method. International Journal of Thermal Sciences, 2022, 179: 107621.

[112] Qiu L, Ning Z., Feng Y.H., et al., A review of recent advances in thermophysical properties at the nanoscale: From solid state to colloids. Physics Reports. 2020, 843: 1–81.

[113] Zou H., Chen C., Zha M.X., et al., A neural regression model for predicting thermal conductivity of CNT nanofluids with multiple base fluids. Journal of Thermal Science, 2021, 30, 1908–1916.

[114] Montazerian A., Øverli J.A., Goutianos S., Thermal conductivity of cementitious composites reinforced with graphene-based materials: An integrated approach combining machine learning with computational micromechanics. Construction and Building Materials, 2023, 395: 132293.

[115] Liu B., Vu-Bac N., Rabczuk T., A stochastic multiscale method for the prediction of the thermal conductivity of Polymer nanocomposites through hybrid machine learning algorithms. Composite Structures, 2021, 273: 114269.

[116] Hashemi M.S., Safdari M., Sheidaei A., A supervised machine learning approach for accelerating the design of particulate composites: Application to thermal conductivity. Computational Materials Science, 2021, 197: 110664.

[117] Wu Y.J., Fang L., Xu Y., Predicting interfacial thermal resistance by machine learning. NPJ Computational Materials, 2019, 5: 1–2.

[118] Azuma K., Hatakeyama T., Nakagawa S., Measurement of surface roughness dependence of thermal contact resistance under low pressure condition. International Conferenceon Electronics Packaging and iMAPS All Asia Conference, Kyoto, Japan, 2015, pp: 381–384.

[119] Dou R., Ge T., Liu X., et al., Effects of contact pressure, interface temperature, and surface roughness on thermal contact conductance between stainless steel surfaces under atmosphere condition. International Journal of Heat and Mass Transfer, 2016, 94: 156–163.

[120] Feng B., Zhang Y.H., Tu J., et al., Correlating the thermal contact resistance between metal/erythritol interfaces with surface roughness andcontact pressure. International Journal of Heat and Mass Transfer, 2021, 176: 121407.

[121] Feng B., Zhang Y.H., Tu J., et al., Determination on the thermal conductivity and thermal contact resistance of thin composite phase change films as a thermal interfacial material. Case Studies in Thermal Engineering, 2022, 33: 101979.

[122] Hao G., Liu Z., Thermal contact resistance enhancement with aluminum oxide layer generated on TiAlN-coated tool and its effect on cutting performance for H13 hardened steel. Surface and Coatings Technology, 2020, 385: 125436.

[123] Mian M.N., Al-Astrabadi F.R., O'Callaghan P.W., et al., Thermal resistance of pressed contacts between steel surfaces: influence of oxide films. Journal of Mechanical Engineering Science, 1979, 21: 159–166.

[124] Bi D., Chen H., Ye T., Influences of temperature and contact pressure on thermal contact resistance at interfaces at cryogenictemperatures. Cryogenics, 2012, 52: 403–409.

[125] Yeh C.L., Wen C.Y., Chen Y.F., et al., An experimental investigation of thermal contact conductance across bolted joints. Experimental Thermal and Fluid Science, 2001, 25: 349–357.

[126] Jalalpour M., Kim J.J., Reda T.M.M., Monitoring of L-shape bolted joint tightness using thermal contact resistance. Experimental Mechanics, 2013, 53: 1531–1543.

[127] Xian Y., Zhang P., Zhai S., et al., Re-estimation of thermal contact resistance considering near-field thermal radiation effect. Applied Thermal Engineering, 2019, 157: 113601.

[128] Rogers G.F.C., Heat transfer at the interface of dissimilar metals. International Journal of Heat and Mass Transfer, 1961, 2: 150–154.

[129] Lewis D.V., Perkins H.C., Heat transfer at the interface of stainless steel and aluminum the influence of surface conditions on the directional effect. International Journal of Heat and Mass Transfer, 1968, 11: 1371–1383.

[130] Clausing A.M., Heat transfer at the interface of dissimilar metals-the influence of thermal strain. International Journal of Heat and Mass Transfer, 1966, 9: 791–801.

[131] Zhong W.R., Huang W.H., Deng X.R., et al., Thermal rectification in thickness-asymmetric graphene nanoribbons. Applied Physics Letters, 2011, 99: 193104.

[132] Feng C.P., Yang L.Y., Yang J., et al., Recent advances in polymer-based thermal interface materials for thermal management: A mini-review. Composites Communications, 2020, 22: 100528.

[133] Abbas A., Zhao Y., Zhou J., et al., Improving thermal conductivity of cotton fabrics using composite coatings containing graphene, multiwall carbon nanotube or boron nitride fine particles. Fibers and Polymers, 2013, 14: 1641–1649.

[134] Feng C.P., Bai L., Bao R.Y., et al., Superior thermal interface materials for thermal management. Composites Communications, 2019, 12: 80–85.

[135] Wang L., Liu Y., Zhang Z., et al., Polymer composites-based thermoelectric materials and devices. Composite Part B: Engineering, 2017, 122: 145–155.

[136] Cao Z., Xia Y., Ge X., Conductive capacity and tribological properties of several carbon materials in conductive greases. Industrial Lubrication and Tribology, 2016, 68: 577–585.

[137] Prasher R.S., Matayabas J.C., Thermal contact resistance of cured gel polymeric thermal interface material. IEEE Transactions on Components and Packaging Technologies, 2004, 27: 702–709.

[138] Alim M., Abdullah M.Z., Aziz M.S.A., et al., Recent advanceson thermally conductive adhesive in electronic packaging: A review. Polymers, 2021, 13: 3337.

[139] Mirmira S.R., Marotta E., Fletcher L.S., Thermal contact conductance of elastomeric gaskets. Journal of Thermophysics and Heat Transfer, 1998, 12(3): 454–456.

[140] Zhang Y., Li W., Huang J., et al., Expanded graphite/paraffin/silicone rubber as high temperature form-stabilized phase change materials for thermal energy storage and thermal interface materials. Materials, 2020, 13: 894.

[141] Mark J.E., Burak E., Roland M.C., The science and technology of rubber. Academic Press, Waltham, 2013.

[142] Zhang F., Feng Y., Feng W., Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Materials Science and Engineering: R: Reports, 2020, 142: 100580.

[143] Zhang Y., Choi J.R., Park S.J., Enhancing the heat and load transfer efficiency by optimizing the interface of hexagonal boron nitride/elastomer nanocomposites for thermal management applications. Polymer, 2018, 143: 1–9.

[144] Ouyang Y., Bai L., Tian H., et al., Recent progress of thermal conductive ploymer composites: Al2O3 fillers, properties and applications. Composites Part A: Applied Science and Manufacturing, 2022, 152: 106685.

[145] Yu S., Lee J.W., Han T.H., et al., Copper shell networks in polymer composites for efficient thermal conduction. ACS Applied Materials & Interfaces, 2013, 5: 11618–11622.

[146] Yao Y., Sun J., Zeng X., et al., Construction of 3D skeleton for polymer composites achieving a high thermal conductivity. Small, 2018, 14: 1704044.

[147] Kim K., Ju H., Kim J., Vertical particle alignment of boron nitride and silicon carbide binary filler system for thermal conductivity enhancement. Composites Science and Technology, 2016, 123: 99–105.

[148] Chen J., Huang X., Sun B., et al., Highly thermally conductive yet electrically insulating polymer/boron nitride nanosheets nanocomposite films for improved thermal management capability. ACS Nano, 2018, 13: 337–345.

[149] Zhang X., Zhang J., Zhang X., et al., Toward high efficiency thermally conductive and electrically insulating pathways through uniformly dispersed and highly oriented graphites close-packed with SiC. Composites Science and Technology, 2017, 150: 217–226.

[150] Ren Y., Guo H., Liu Y., et al., A trade-off study toward highly thermally conductive and mechanically robust thermoplastic composites by injection moulding. Composites Science and Technology, 2019, 183: 107787.

[151] Han G., Zhang D., Kong C., et al., Flexible, thermostable and flame-resistant epoxy-based thermally conductive layered films with aligned ionic liquid-wrapped boron nitride nanosheets viacyclic layer-by-layer blade-casting. Chemical Engineering Journal, 2022, 437: 135482.

[152] Nishihora R.K., Rachadel P.L., Quadri M.G.N., et al., Manufacturing porous ceramic materials by tape casting—A review. Journal of the European Ceramic Society, 2018, 38: 988–1001.

[153] Ma H., Gao B., Wang M., et al., Strategies for enhancing thermal conductivity of polymer-based thermal interface materials: A review. Journal of Materials Science, 2021, 56: 1064–1086.

[154] Pan D., Li Q., Zhang W., et al., Highly thermal conductive epoxy nano-composites filled with 3D BN/C spatial network prepared by salt template assisted method. Composites Part B: Engineering, 2021, 209: 108609.

[155] Lin C.H., Izard A.G., Valdevit L., et al., Mechanically compliant thermal interfaces using biporous copper-polydimethylsiloxane interpenetrating phase composite. Advanced Materials Interfaces, 2021, 8: 2001423.

[156] Chung S.H., Kim H., Jeong S.W., Improved thermal conductivity of carbon-based thermal interface materials by high-magnetic-field alignment. Carbon, 2018, 140: 24–29.

[157] Song Q.S., Zhu W., Deng Y., et al., Enhanced through-plane thermal conductivity and high electrical insulation of flexible composite films with aligned boron nitride for thermal interface material. Composites Part A: Applied Science and Manufacturing, 2019, 127: 105654.

[158] Wang H., Tazebay A.S., Yang G., et al., Highly deformable thermal interface materials enabled by covalently-bonded carbon nanotubes. Carbon, 2016, 106: 152–157.

[159] Sun Y., Tang B., Huang W., et al., Preparation of graphene modified epoxy resin with high thermal conductivity by optimizing the morphology of filler. Applied Thermal Engineering, 2016, 103: 892–900.

[160] Ralphs M.I., Kemme N., Vartak P.B., et al., In situ alloying of thermally conductive polymer composites by combining liquid and solid metal micro additives. ACS Applied Materials & Interfaces, 2018, 10: 2083–2092.

[161] Bae Y.H., Yu M.J., Vu M.C., et al., Synergistic effects of segregated network by polymethylmethacrylate beads and sintering of copper nanoparticles on thermal and electrical properties of epoxy composites. Composites Science and Technology, 2018, 155: 144–150.

[162] Tang B., Wang Z.W., Huang W.Q., et al., RGO and three-dimensional graphene networks co-modified TIMs with high performances. Nanoscale Research Letters, 2017, 12: 1–7.

[163] Pan G., Yao Y., Zeng X., et al., Learning from natural nacre: constructing layered polymer composites with high thermal conductivity. ACS Applied Materials & Interfaces, 2017, 9: 33001–33010.

[164] Zhang Y.F., Ren Y.J., Bai S.L., Vertically aligned graphene film/epoxy composites as heat dissipating materials. International Journal of Heat and Mass Transfer, 2018, 118: 510–517.

[165] Zhang Y.F., Han D., Zhao Y.H., et al., High-performance thermal interface materials consisting of vertically aligned graphene film and polymer. Carbon, 2016, 109: 552–557.

[166] Yao Y., Zhu X., Zeng X., et al., Vertically aligned and interconnected SiC nanowire networks leading to significantly enhanced thermal conductivity of polymer composites. ACS Applied Materials & Interfaces, 2018, 10: 9669–9678.

[167] Li X.H., Liu P., Li X., et al., Vertically aligned, ultralight and highly compressive all-graphitized graphene aerogels for highly thermally conductive polymer composites. Carbon, 2018, 140: 624–633.

[168] Li C., Tan L.Y., Zeng X.L., et al., Polymer composites with high thermal conductivity optimized by polyline-folded graphite paper. Composites Science and Technology, 2020, 188: 107970.

[169] Ge X., Liang W.J., Ge J.F., et al., Hexagonal boron nitride/microfibril cellulose/poly (vinyl alcohol) ternary composite film with thermal conductivity and flexibility. Materials, 2018, 12: 104.

[170] Chung S.H., Kim H., Jeong S.W., Improved thermal conductivity of carbon-based thermal interface materials by high-magnetic-field alignment. Carbon, 2018, 140: 24–29.

[171] Nan C.W., Birringer R., Clarke D.R., et al., Effective thermal conductivity of particulate composites with interfacial thermal resistance. Journal of Applied Physics, 1997, 81: 6692–6699.

[172] Song J., Tian K., Ma L., et al., The effect of carbon black morphology to the thermal conductivity of natural rubber composites. International Journal of Heat and Mass Transfer, 2019, 137: 184–191.

[173] Bruggeman D.A.G., Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. Annalen der Physik, 1935, 24(7): 636–664.

[174] Liang J.Z., Liu G.S., A new heat transfer model of inorganic particulate-filled polymer composites. Journal of Materials Science, 2009, 44: 4715–4720.

[175] Jung J., Jeong S.H., Hjort K., et al., Investigation of thermal conductivity for liquid metal composites using the micromechanics-based mean-field homogenization theory. Soft Matter, 2020, 16: 5840–5847.

[176] Razeeb K.M., Dalton E., Cross G.L.W., et al., Present and future thermal interface materials for electronic devices. International Materials Reviews, 2018, 63: 1–21.

[177] Sarvar F., Whalley D.C., Conway P.P., Thermal interface materials—A review of the state of the art. 2006 1st Electronic System Integration Technology Conference, Dresden, Germany, 2006, pp: 1292–1302.

[178] Hansson J., Nilsson T.M.J., Ye L., et al., Novel nano structured thermal interface materials: a review. International Materials Reviews, 2018, 63: 22–45.

[179] Chen S., Wang H.Z., Zhao R.Q., et al., Liquid metal composites. Matter, 2020, 2: 1446–1480.

[180] Olson E.A., Efremov M.Y., Zhang M., et al., Size-dependent melting of Bi nano particles. Journal of Applied Physics, 2005, 97(3): 034304.

[181] Yu H., Li L., Zhang Y., Silver nanoparticle-based thermal interface materials with ultra-low thermal resistance for power electronics applications. Scripta Materialia, 2012, 66: 931–934.

[182] Raj P.M., Gangidi P.R., Nataraj N., et al., Coelectrodeposited solder composite films for advanced thermal interface materials. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2013, 3: 989–996.

[183] Sharma M., Chung D.D.L., Solder-graphite network composite sheets as high-performancethermal interface materials. Journal of Electronic Materials, 2015, 44: 929–947.

[184] Gao Y., Liu J., Gallium-based thermal interface material with high compliance and wettability. Applied Physics A, 2012, 107: 701–708.

[185] Tang J., Zhao X., Li J., et al., Gallium-based liquid metal amalgams: transitional-state metallic mixtures (TransM2ixes) with enhanced and tunable electrical, thermal, and mechanical properties. ACS Applied Materials & Interfaces, 2017, 9: 35977–35987.

[186] Takabatake T., Suekuni K., Nakayama T., et al., Phonon-glass electron-crystal thermoelectric clathrates: Experiments and theory. Reviews of Modern Physics, 2014, 86: 669.

[187] Maxwell-Garnett J.C., Colours in metal glasses and in metallic films. Proceedings of the Royal Society of London, 1904, 73: 488–496.

[188] Ralphs M.I., Kemme N., Vartak P.B., et al., In situ alloying of thermally conductive polymer composites by combining liquid and solid metal micro additives. ACS Applied Materials & Interfaces, 2018, 10: 2083–2092.

[189] Tavangar R., Molina J.M., Weber L., Assessing predictive schemes for thermal conductivity against diamond-reinforced silver matrix composites at intermediate phase contrast. Scripta Materialia, 2007, 56: 357–360.

[190] Zhu L., Hess D.W., Wong C.P., Assembling carbon nanotube films as thermal interface material. 57th Electronic Components and Technology Conference, Sparks, NV, USA, 2007.

DOI: 10.1109/ECTC.2007.374077

[191] Lv P., Tan X.W., Yu K.H., et al., Super-elastic graphene/carbon nanotube aerogel: A novel thermal interface material with highly thermal transport properties. Carbon, 2016, 99: 222–228.

[192] Dai W., Ma T., Yan Q., et al., Metal-level thermally conductive yet soft graphene thermal interface materials. ACS Nano, 2019, 13: 11561–11571.