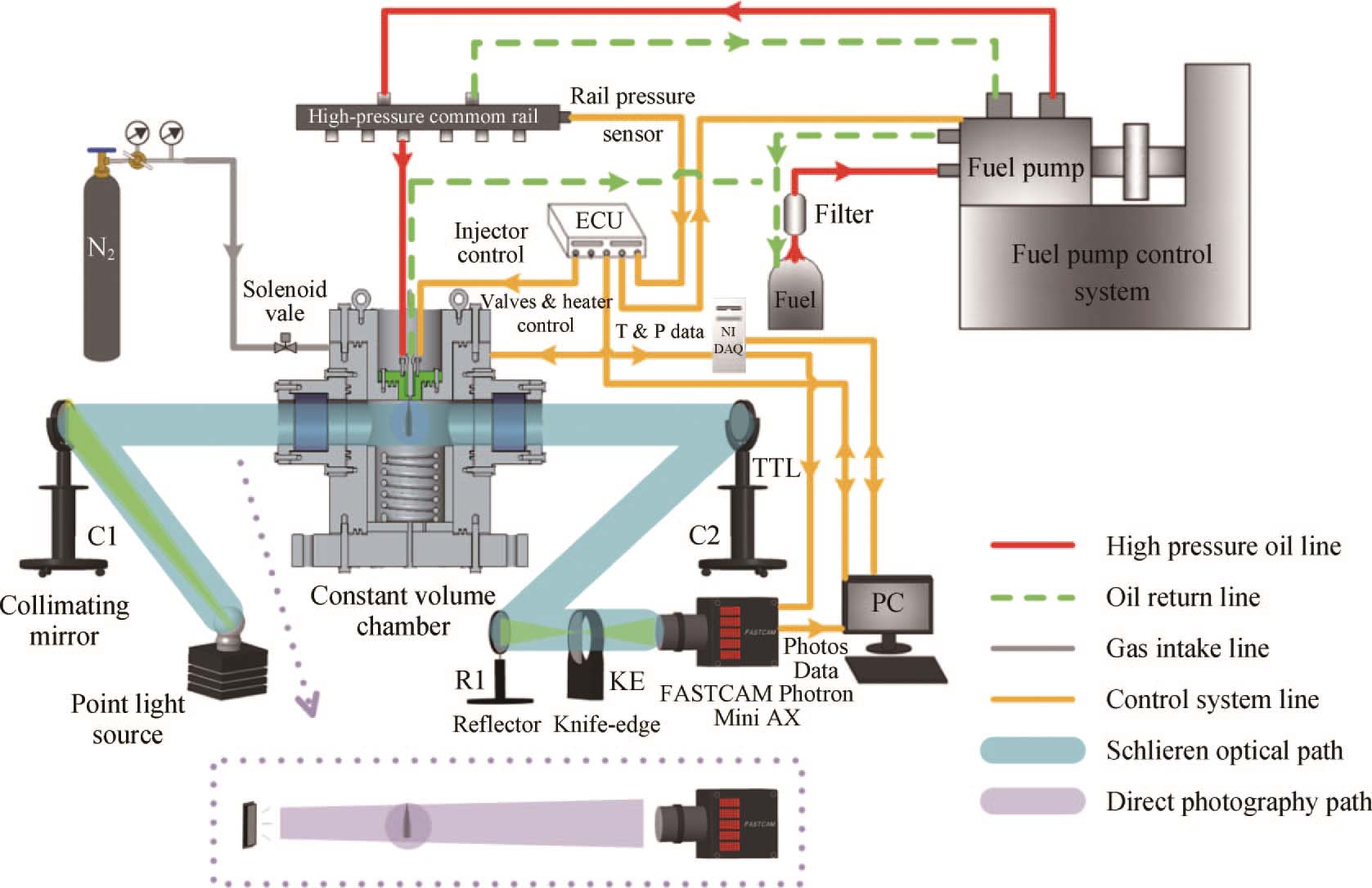

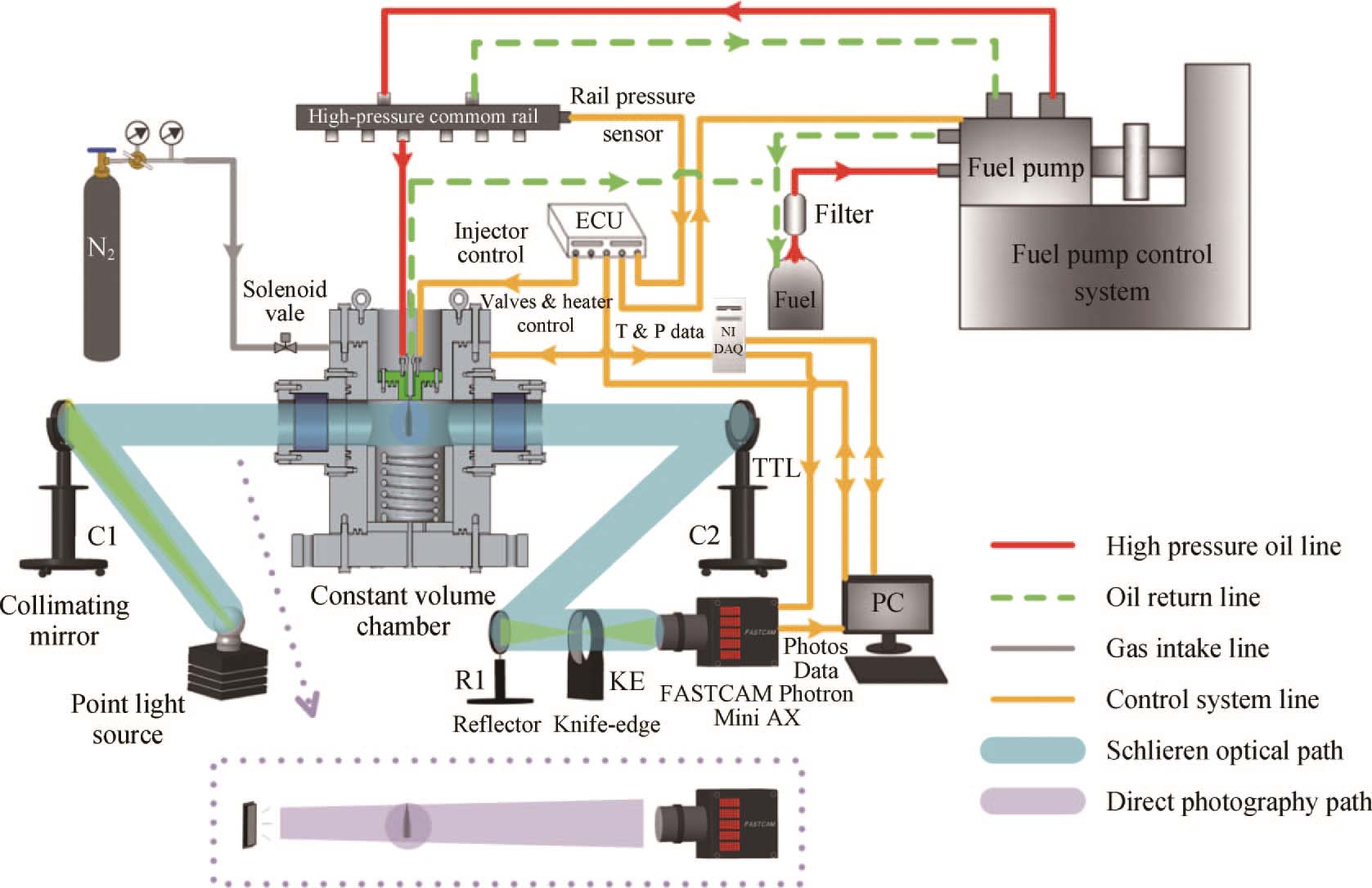

The asymmetry of the multi-orifice spray will cause uneven heat load of the marine diesel engine, thereby affecting its working performance and service life. Therefore, an in-depth understanding of the spray and flame characteristics of multi-orifice nozzles will guide the optimization of the nozzle structure, needle design and diesel atomization and combustion process. For this reason, four groups of dual-orifice nozzles with different hole diameters (0.1–0.55 mm) and mass flow rates covering the typical marine medium-speed diesel injections are designed and customized, and the constant volume chamber (CVC) with high temperature and pressure is used to simulate the actual in-cylinder working conditions of the diesel engine for the spray visualization experiment. To study the asymmetry of the fuel sprays discharged from a diesel injector, the multi-orifice nozzle is simplified as a dual-orifice nozzle in this study. Combined with X-ray Computed Tomography (CT) imaging technology, the influences of the nozzle internal structure on the spray and flame asymmetry are studied in the constructed supercritical environment. It is found that the asymmetry of the inlet angle and the equivalent length-diameter ratio is positively correlated with the inconsistency of the dual sprays. With an increase in the injection pressure and nozzle diameter, the asymmetry of the dual spray becomes more pronounced, resulting in greater disparities in the ignition delay times and ignition positions of the two sprays. Moreover, the increase in nozzle diameter also leads to combustion instability, resulting in a flame with a serrated appearance. With the increase of ambient temperature, the proportion of liquid phase in the jet decreases and the relative density of spray front decreases.

[1] International Energy Outlook 2021: With projections to 2050. https://www.eia.gov/outlooks/ieo/index.php, 2021 (accessed on May 13, 2021).

[2] Organization International Maritime, Report of the marine environment protection committee on its seventy-first session. MEPC 71/17, 2017.

[3] Societies International Association of Classification, IACS UR M77-Storage and Use of SCR Reductants. 2016.

[4] The Ministry of Ecology and Environment, The People’s Republic of China, Limits and measurement methods for exhaust pollutants from marine engines (China I, II). 2016.

[5] Du X., Thoughts on strategies and paths to achieve carbon peaking and carbon neutrality in China. Frontiers in Energy, 2023, 17(3): 324–331.

[6] Guo G., He Z., Lai M.-C., Duan X., Leng X., Duan L., Chen Z., Optical experiment and large eddy simulation on effects of in-nozzle stagnant air bubbles and diesel on near-nozzle spray structure variation in diesel injector. Fuel, 2019, 255: 115721.

[7] Jafarmadar S., Three-dimensional modeling and exergy analysis in combustion chambers of an indirect injection diesel engine. Fuel, 2013, 107: 439–447.

[8] Liu H., Chen B., Feng L., Wang Y., Yi W., Yao M., Study on fuel distribution of wall-impinging diesel spray under different wall temperatures by laser-induced exciplex fluorescence (LIEF). Energies, 2018, 11(5): 1249.

[9] Feng L., Sun X., Pan X., Yi W., Cui Y., Wang Y., Wen M., Ming Z., Liu H., Yao M., Gasoline spray characteristics using a high pressure common rail diesel injection system by the method of laser induced exciplex fluorescence. Fuel, 2021, 302: 121174.

[10] Wiesmann F., Han D., Qiu Z., Strauβ L., RIEβ S., Wensing M., Lauer T., Numerical study of novel OME1-6 combustion mechanism and spray combustion at changed ambient environments. Frontiers in Energy, 2024, 18(4): 483–505.

[11] Wu X., Deng J., Cui H., Xue F., Zhou L., Luo F., Numerical simulation of injection rate of each nozzle hole of multi-hole diesel injector. Applied Thermal Engineering, 2016, 108: 793–797.

[12] Lešnik L., Kegl B., Bombek G., Hočevar M., Biluš I., The influence of in-nozzle cavitation on flow characteristics and spray break-up. Fuel, 2018, 222: 550–560.

[13] Yin B., Ye Z., Jia H., Yu S., Deng W., Experimental study on the penetration of diesel and biodiesel spray liquid emerging from an equilateral triangular orifice under evaporative conditions. Journal of Thermal Science, 2022, 31(5): 1565–1574.

[14] Ma H., Zhang T., An Q., Tao Y., Xu Y., Visualization experiment and numerical analysis of cavitation flow characteristics in diesel fuel injector control valve with different structure design. Journal of Thermal Science, 2021, 30: 76–87.

[15] Zhou Z.-F., Liang L., Murad S. H. M., Camm J., Davy M., Investigation of fuel volatility on the heat transfer dynamics on piston surface due to the pulsed spray impingement. International Journal of Heat and Mass Transfer, 2021, 170: 121008.

[16] Sedarsky D., Idlahcen S., Rozé C., Blaisot J.-B., Velocity measurements in the near field of a diesel fuel injector by ultrafast imagery. Experiments in Fluids, 2013, 54(2): 1451.

[17] Guo G., He Z., Wang Q., Lai M.-C., Zhong W., Guan W., Wang J., Numerical investigation of transient hole-to-hole variation in cavitation regimes inside a multi-hole diesel nozzle. Fuel, 2021, 287: 119457.

[18] Chiavola O., Palmieri F., On a modified VCO nozzle layout for diesel common rail injectors under actual needle displacement. Energy Procedia, 2017, 126: 1027–1034.

[19] He Z., Zhong W., Wang Q., Jiang Z., Shao Z., Effect of nozzle geometrical and dynamic factors on cavitating and turbulent flow in a diesel multi-hole injector nozzle. International Journal of Thermal Sciences, 2013, 70: 132–143.

[20] Coratella C., Sahu A., Parry L., Xu H., Ma X., Experimental investigation of the orifice-to-orifice variability in jet velocities in a diesel injector. Fuel, 2020, 280: 118353.

[21] Xia J., Huang Z., Xu L., Ju D., Lu X., Experimental study on spray and atomization characteristics under subcritical, transcritical and supercritical conditions of marine diesel engine. Energy Conversion and Management, 2019, 195: 958–971.

[22] Huang Z., Zhang W., Xia J., Ju D., Lu X., A multi-component surrogate of commercial diesel for trans-critical and supercritical injections study. Fuel, 2019, 243: 590–602.

[23] Naber J., Siebers D., Effects of gas density and vaporization on penetration and dispersion of diesel sprays. SAE Technical Paper 960034, 1996.