[1] Tsinghua University Building Energy Efficiency Research Center, Annual report on China building energy efficiency. China Building Industry Press, 2018, pp: 7–8.

[2] Davraz M., Koru M., Akdag A.E., et al., Investigating the use of raw perlite to produce monolithic thermal insulation material. Construction and Building Materials, 2020, 263: 120674.

[3] Zeng C., Yuan Y.P., Haghighat F., et al., Application of PCM-based thermal energy storage system in buildings: a state of the art review on the mathematical modeling approaches and experimental investigations. Journal of Thermal Science, 2022, 31(6): 1821–1852.

[4] Fantucci S., Garbaccio S., Lorenzati A., et al., Thermo-economic analysis of building energy retrofits using VIP-Vacuum insulation panels. Energy and Buildings, 2019, 196: 269–279.

[5] Liu L.F., Si Z., Li H.Q., et al., Experimental physical properties of an eco-friendly bio-insulation material based on wheat straw for buildings. Energy and Buildings, 2019, 201: 19–36.

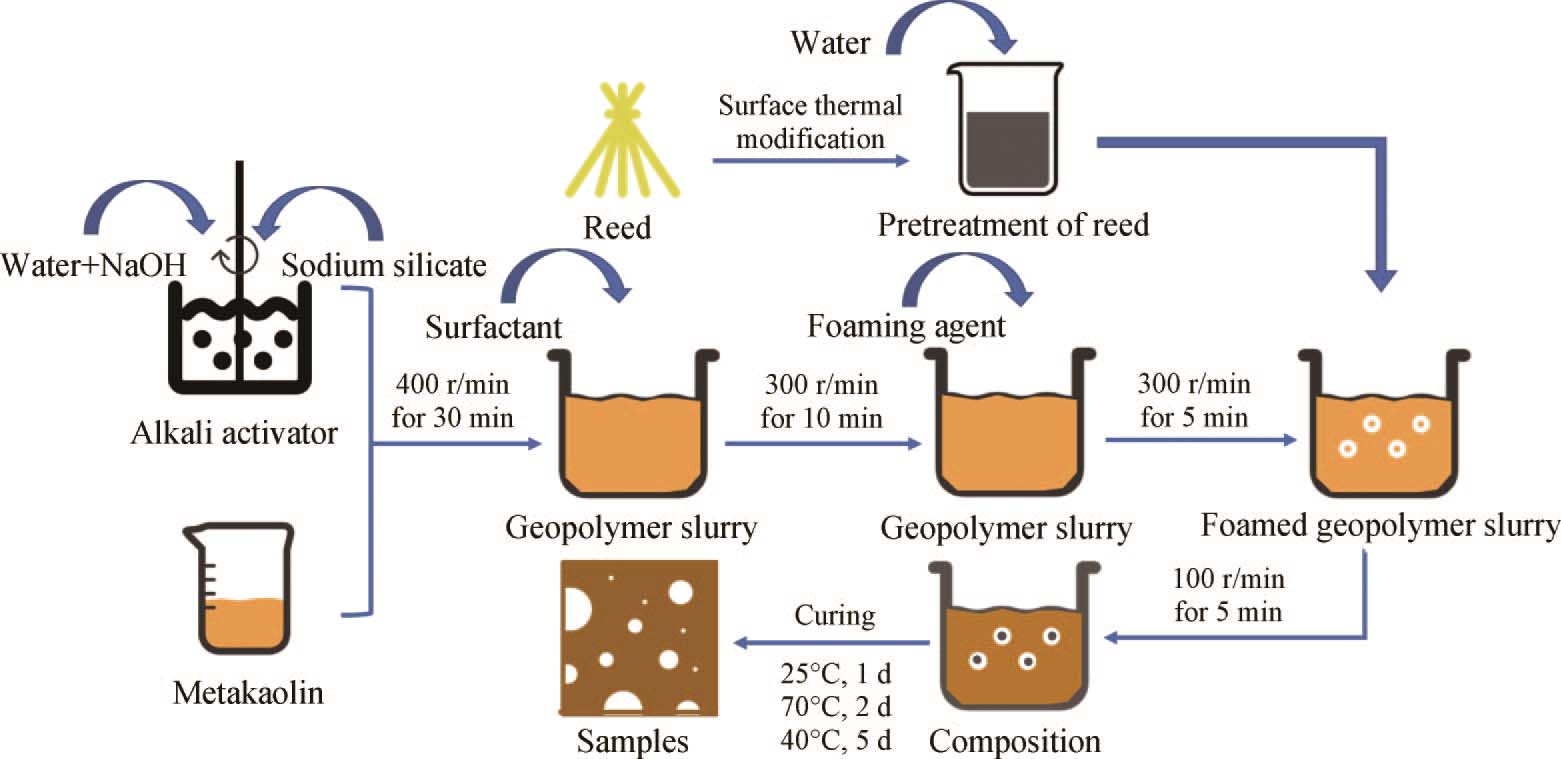

[6] Wang S., Li H.Q., Si Z., et al., Experimental research on a feasible rice husk/geopolymer foam building insulation material. Energy and Buildings, 2020, 226: 110358.

[7] Hultberg M., Prade T., Bodin H., et al., Adding benefit to wetlands—Valorization of harvested common reed through mushroom production. Science of the Total Environment, 2018, 637–638: 1395–1399.

[8] Bakatovich, A., Gaspar F., Composite material for thermal insulation based on moss raw material. Construction and Building Materials, 2019, 228: 116699.

[9] Ouakarrouch M., Bousshine S., Bybi A., et al., Acoustic and thermal performances assessment of sustainable insulation panels made from cardboard waste and natural fibers. Applied Acoustics, 2022, 199: 109007.

[10] Savic A., Antonijevic D., Jelic I., et al., Thermomechanical behavior of bio-fiber composite thermal insulation panels. Energy and Buildings, 2020, 229: 110511.

[11] Mucsi Z.M., Hasan K.M.F., Horváth P.G., et al., Semi-dry technology mediated lignocellulosic coconut and energy reed straw reinforced cementitious insulation panels. Journal of Building Engineering, 2022, 57: 104825.

[12] Moujoud Z., Sair S., Ousaleh H.A., et al., Geopolymer composites reinforced with natural Fibers: A review of recent advances in processing and properties. Construction and Building Materials, 2023, 388: 131666.

[13] Suwan T., Maichin P., Fan M., et al., Influence of alkalinity on self-treatment process of natural fiber and properties of its geopolymeric composites. Construction and Building Materials, 2022, 316: 125817.

[14] Chen M.H., Tong H., Liu H., et al., A cyclic process for enzymatic hydrolysis and fermentation of lactic acid pretreated reed. Industrial Crops and Products, 2022, 181: 114848.

[15] Chen M.H., Wang Y.Q., Lu J., et al., Combinatorial pretreatments of reed straw using liquid hot water and lactic acid for fermentable sugar production. Fuel, 2023, 331: 125916.

[16] Zhang X.Y., Wang Y.Q, Lu J., et al., Biosurfactant promoted enzymatic saccharification of alkali-pretreated reed straw. Bioresource Technology, 2023, 372: 128665.

[17] Xie T., Wei R.C., Wang Z., et al., Comparative analysis of thermal oxidative decomposition and fire characteristics for different straw powders via thermogravimetry and cone calorimetry. Process Safety and Environmental Protection, 2020, 134: 121–130.

[18] Ge Y.P., Tian X., Huang D.W., et al., Understanding efflorescence behavior and compressive strength evolution of metakaolin-based geopolymer under a pore structure perspective. Journal of Building Engineering, 2023, 66: 105828.

[19] Beatriz M., Almeida J., Tadeu A., et al., Rice husk cement-based composites for acoustic barriers and thermal insulating layers. Journal of Building Engineering, 2021, 39: 102297.

[20] Raveendran K., Ganesh A., Khilar K.C., Pyrolysis characteristics of biomass and biomass components. Fuel, 1996, 75(8): 987–998.

[21] Biswas A.K., Umeki K., Yang W.H., et al., Change of pyrolysis characteristics and structure of woody biomass due to steam explosion pretreatment. Fuel Processing Technology, 2011, 92(10): 1849–1854.

[22] Jacquet N., Quiévy N., Vanderghem C., et al., Influence of steam explosion on the thermal stability of cellulose fibres. Polymer Degradation and Stability, 2011, 96: 1582–1588.

[23] Zhao J.J., Wang X., Li S., et al., Polypropylene fiber reinforced alkali-activated ultra-light foam insulation material: Performance study and mechanism analysis. Construction and Building Materials, 2023, 405: 133241.

[24] Aliaksandr B., Gaspar F., Boltrushevich N., Thermal insulation material based on reed and straw fibres bonded with sodium silicate and rosin. Construction and Building Materials, 2022, 352: 129055.

[25] Bakharev T., Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperature curing. Cement and Concrete Research, 2006, 36: 1134–1147.

[26] GB 8624, Classification for the burning behavior of building materials and products. Standards Press of China, 2012, pp: 4.

[27] Viel M., Collet F., Lecieux Y., et al., Resistance to mold development assessment of bio-based building materials. Composites Part B: Engineering, 2019, 158: 406–418.

[28] Longhi M.A., Zhang Z.H., Walkley B., et al., Strategies for control and mitigation of efflorescence in metakaolin-based geopolymers. Cement and Concrete Research, 2021, 144: 106431.

[29] Kani E.N., Allahverdi A., Provis J.L., Efflorescence control in geopolymer binders based on natural pozzolan. Cement and Concrete Composites, 2012, 34(1): 25–33.

[30] Poletanovic B., Janotka I., Janek M., et al., Influence of the NaOH-treated hemp fibres on the properties of fly-ash based alkali-activated mortars prior and after wet/dry cycles. Construction and Building Materials, 2021, 309: 125072.

[31] Song X.P., Hao Y.X., Huang J., et al., Study on mechanical properties and destabilization mechanism of unclassified tailings consolidation body under the action of dry-wet cycle. Construction and Building Materials, 2023, 365: 130022.