[1] Slotnick J.P., Khodadoust A., Alonso J.J., Darmofal D.L., Gropp W.D., Lurie E.A., Mavriplis D.J., Venkatakrishnan V., Enabling the environmentally clean air transportation of the future: A vision of computational fluid dynamics in 2030. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2014, 372(2022): 20130317. DOI: 10.1098/rsta.2013.0317

[2] Zambonini G., Ottavy X., Kriegseis J., Corner separation dynamics in a linear compressor cascade. Journal of Fluids Engineering, 2017, 139(6): 061101. DOI: 10.1115/1.4035876

[3] Yan H., Liu Y.W., Li Q.S., Lu L.P., Turbulence characteristics in corner separation in a highly loaded linear compressor cascade. Aerospace Science and Technology, 2018, 75(1): 139–154.

[4] Cao Z.Y., Liu B., Zhang T., Yang X.Q., Chen P.P., Influence of coupled boundary layer suction and bowed blade on flow field and performance of a diffusion cascade. Chinese Journal of Aeronautics, 2017, 30(1): 249–263.

[5] Cao Z.Y., Song C., Gao X., Zhang X., Liu B., Computational study on the boundary layer suction effects in the supersonic compressor flow with a bowed blade. Journal of Thermal Science, 2022, 31(2): 511–528.

[6] Liu Y.W., Sun J.J., Lu L.P., Corner separation control by boundary layer suction applied to a highly loaded axial compressor cascade. Energies, 2014, 7(12): 7994–8007.

[7] Li Y.H., Wu Y., Zhou M., Su C.B., Zhang X.W., Zhu J.Q., Control of the corner separation in a compressor cascade by steady and unsteady plasma aerodynamic actuation. Experiments in Fluids, 2010, 48(6): 1015–1023.

[8] Akcayoz E., Vo H.D., Mahallati A., Controlling corner stall separation with plasma actuators in a compressor cascade. Journal of Turbomachinery, 2016, 138(8): 081008. DOI: 10.1115/1.4032675

[9] Zhang H.D., Yu X.J., Liu B.J., Wu Y., Li Y.H., Control of corner separation with plasma actuation in a high-speed compressor cascade. Applied Sciences, 2017, 7(5): 465. DOI: 10.3390/app7050465

[10] Meng Q.H., Du X., Chen S.W., Wang S.T., Numerical study of dual sweeping jet actuators for corner separation control in compressor cascade. Journal of Thermal Science, 2021, 30(1): 201–209.

[11] Staats M., Nitsche W., Active control of the corner separation on a highly loaded compressor cascade with periodic nonsteady boundary conditions by means of fluidic actuators. Journal of Turbomachinery, 2016, 138(3): 031004. DOI: 10.1115/1.4031934

[12] Cao Z.Y., Gao X., Zhang X., Zhang F., Liu B., Influence of endwall air injection with discrete holes on corner separation of a compressor cascade. Journal of Thermal Science, 2021, 30(5): 1684–1704.

[13] Zhang J., Du J., Zhang M., Chen Z., Zhang H.W., Nie C.Q., Aerodynamic performance improvement of a highly loaded compressor airfoil with coanda jet flap. Journal of Thermal Science, 2022, 31(1): 151–162.

[14] Meng T.T., Yang G., Zhou L., Ji L.C., Full blended blade and endwall design of a compressor cascade. Chinese Journal of Aeronautics, 2021, 34(11): 79–93.

[15] Chu W.L., Li X.J., Wu Y.H., Zhang H.G., Reduction of end wall loss in axial compressor by using non-axisymmetric profiled end wall: a new design approach based on end wall velocity modification. Aerospace Science and Technology, 2016, 55: 76–91. DOI: 10.1016/j.ast.2016.05.011

[16] Cao Z.Y., Gao X., Song C., Zhang X., Zhang F., Liu B., Performance enhancing for a highly loaded tandem cascade by endwall incoming vortex–corner separation interaction. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2021, 235(23): 6833–6846.

[17] Hergt A., Meyer R., Engel K., Effects of vortex generator application on the performance of a compressor cascade. Journal of Turbomachinery, 2013, 135(2): 021026. DOI: 10.1115/1.4006605

[18] Fu H., Zhou L., Ji L.C., Influence of sub boundary layer vortex generator height and attack angle on cross-flows in the hub region of compressors. Chinese Journal of Aeronautics, 2022, 35(8): 30–44.

[19] Ma S., Chu W.L., Zhang H.G., Li X.J., Kuang H.Y., Effects of modified micro-vortex generators on aerodynamic performance in a high-load compressor cascade. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2019, 233(3): 309–323.

[20] Ma S., Sun X.L., Optimization study on the influence of little blades’ spatial position on a compressor cascade performance. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2022, 236(9): 1799–1816.

[21] Li J.B., Ji L.C., Efficient design method for applying vortex generators in turbomachinery. Journal of Turbomachinery, 2019, 141(8): 081005. DOI: 10.1115/1.4042990

[22] Sun J.J., Ottavy X., Liu Y.W., Lu L.P., Corner separation control by optimizing blade end slots in a linear compressor cascade. Aerospace Science and Technology, 2021, 114: 106737. DOI: 10.1016/j.ast.2021.106737

[23] Tang Y.M., Liu Y.W., Lu L.P., Lu H.W., Wang M., Passive separation control with blade-end slots in a highly loaded compressor cascade. AIAA Journal, 2020, 58(1): 85–97.

[24] Tang Y.M., Liu Y.W., Aerodynamic investigation of datum and slotted blade profiles under different Mach number conditions. Energies, 2020, 13(7): 1673. DOI: 10.3390/en13071673

[25] Hu J.G., Wang R.G., Huang D.Q., Flow control mechanisms of a combined approach using blade slot and vortex generator in compressor cascade. Aerospace Science and Technology, 2018, 78: 320–331. DOI: 10.1016/j.ast.2018.04.034

[26] Lin J.C., Howard F.G., Bushnell D.M., Selby G.V., Investigation of several passive and active methods for turbulent flow separation control. 21st Fluid Dynamics, Plasma Dynamics and Lasers Conference, Seattle, America, 1990, 6: 18–20. DOI: 10.2514/6.1990-1598

[27] Quan P.C., Zhong S., Liu Q., Li L., Attenuation of flow separation using herringbone riblets at M∞=5. AIAA Journal, 2019, 57(1): 142–152.

[28] Xu F., Zhong S., Zhang S.Y., Vortical structures and development of laminar flow over convergent-divergent riblets. Physics of Fluids, 2018, 30(5): 051901. DOI: 10.1063/1.5027522

[29] Sharma V., Dutta S., Experimental and Numerical Investigation of Bio-Inspired Riblet for Drag Reduction. Journal of Fluids Engineering, 2023, 145(2): 021207. DOI: 10.1115/1.4056185

[30] Chen H.W., Rao F.G., Shang X.P., Zhang D.Y., Hagiwara I., Flow over bio-inspired 3D herringbone wall riblets. Experiments in Fluids, 2014, 55(3): 1698. DOI: 10.1007/s00348-014-1698-4

[31] Benschop H.O.G., Breugem W.P., Drag reduction by herringbone riblet texture in direct numerical simulations of turbulent channel flow. Journal of Turbulence, 2017, 18(8): 717–759.

[32] Nugroho B., Hutchins N., Monty J.P., Large-scale spanwise periodicity in a turbulent boundary layer induced by highly ordered and directional surface roughness. International Journal of Heat and Fluid Flow, 2013, 41: 90–102.

DOI: 10.1016/j.ijheatfluidflow.2013.04.003

[33] Guo T.B., Zhong S., Craft T., Control of laminar flow separation over a backward-facing rounded ramp with C-D riblets–The effects of riblet height, spacing and yaw angle. International Journal of Heat and Fluid Flow, 2020, 85: 108629. DOI: 10.1016/j.ijheatfluidflow.2020.108629

[34] Liu Q., Zhong S., Li L., Investigation of riblet geometry and start locations of herringbone riblets on pressure losses in a linear cascade at low Reynolds numbers. Journal of Turbomachinery, 2020, 142(10): 101010. DOI: 10.1115/1.4046960

[35] Liu Q., Zhong S., Li L., Effects of bio-inspired micro-scale surface patterns on the profile losses in a linear cascade. Journal of Turbomachinery, 2019, 141(12): 121006. DOI: 10.1115/1.4044612

[36] Ma W., Ottavy X., Lu L.P., Leboeuf F., Gao F., Experimental study of corner stall in a linear compressor cascade. Chinese Journal of Aeronautics, 2011, 24(3): 235–242.

[37] Ma W., Ottavy X., Lu L.P., Leboeuf F., Intermittent corner separation in a linear compressor cascade. Experiments in Fluids, 2013, 54(6): 1546. DOI: 10.1007/s00348-013-1546-y

[38] Guo T.B., Zhong S., Craft T., Secondary flow in a laminar boundary layer developing over convergent-divergent riblets. International Journal of Heat and Fluid Flow, 2020, 84: 108598. DOI: 10.1016/j.ijheatfluidflow.2020.108598

[39] Sun W., Xu L.P., Improvement of corner separation prediction using an explicit non-linear RANS closure. Journal of the Global Power and Propulsion Society, 2021, 5: 50–65. DOI: 10.33737/jgpps/133913

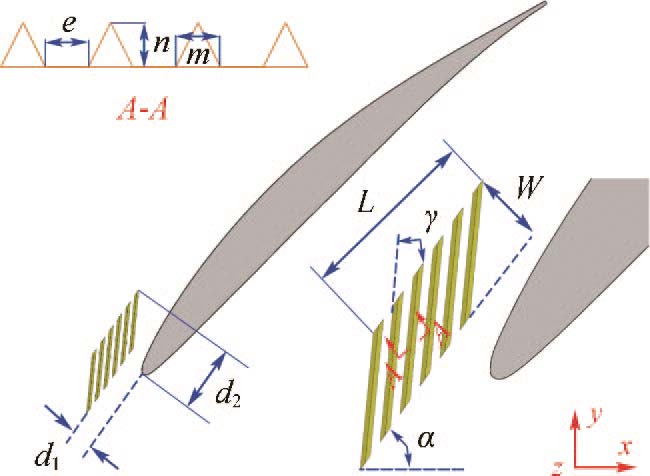

[40] Zhang P., Cheng R.X., Li Y.H., Numerical study on the corner separation control for a compressor cascade via bionic herringbone riblets. Aerospace, 2024, 11(1): 90. DOI: 10.3390/aerospace11010090