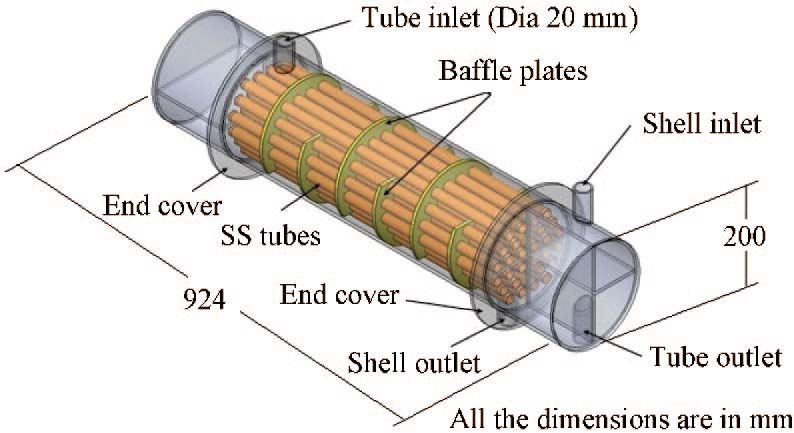

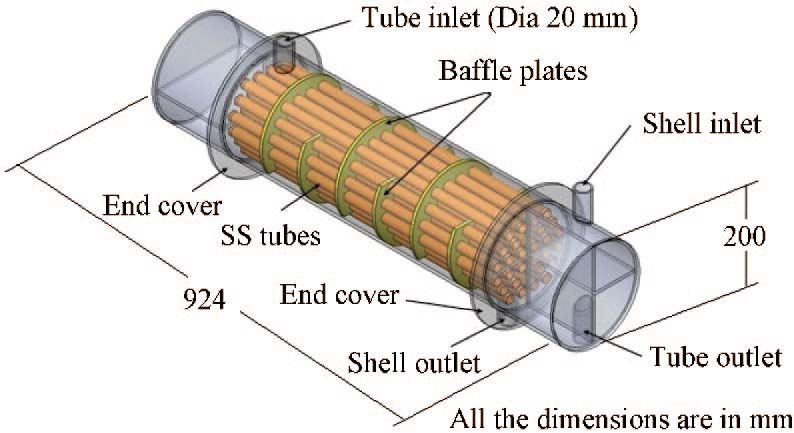

Heat exchangers have the potential for various engineering applications, and their performance is enriched by surface modification. The proposed system enriches the heat exchanger’s performance by adapting a peened stainless steel (SS) surface blasted with copper, grinding, sand, and iron. The influences peened SS surface modified with a copper blast, grinding, sandblast, and iron blast on the surface morphology of shell and tube heat exchanger surface (STHE) is analyzed via tungsten heated cathode electron gun featured scanning electron microscope and observed coarse grain surface. The SS surface featured STHE performance is experimentally evaluated by different flow rates (30, 60, 90, and 120 L/min) underwater fluid medium functioned by the temperature ranges of 25–75°C and its results are compared with computational fluid dynamic (CFD)/heat transfer research (HTRI) analyzed results. The 60 L/min flow rate was spotted as an optimum value for both shell and tube side reasons. The STHE is operated with a 60 L/min flow rate under the different peened surfaces and evaluated its Stanton number, Nusselt number, logarithmic mean temperature difference (LMTD), overall heat transfer coefficient, number of transfer units (NTU), effectiveness, and exergy efficiency. The iron blasted SS peened surface was observed to have better SHTE performance like Stanton number (0.0012), Nusselt number (2180), reduced LMTD of 31°C, improved overall heat transfer co-efficient of 2400 W/(m2∙K), better NTU of 0.5532, good effectiveness value of 0.451 62, and hiked exergy efficiency of 10% respectively.

[1] Musa S.D., Zhongua T., Ibrahim A.O., Habib M., China’s energy status: a critical look at fossils and renewable options. Renewable and Sustainable Energy Reviews, 2018, 81(2): 2281–2290.

[2] Master B.I., Chunangad K.S., Boxma A.J., Kral D., Stehlík P., Most frequently used heat exchangers from pioneering research to worldwide applications. Heat Transfer Engineering, 2007, 27(6): 4–11.

[3] Huadongand L., Kottke V., Effect of baffle spacing on pressure drop and local heat transfer in shell-and-tube heat exchangers for staggered tube arrangement. International Journal of Heat Mass Transfer, 1998, 41(10): 1303–1311.

[4] Dickson W.C., Cheremisinoff P.N., Solar energy technology handbook. Marcel Dekker, New York, 1980.

[5] Bergles A.E., Techniques to augment heat transfer, in: W.M. Rosenhow (Ed.), Handbook of Heat Transfer Applications. McGraw-Hill, New York, 1985.

[6] Poongavanam, Heat transfer and pressure drop performance of solar glycol/activated carbon-based nanofluids in shot peened double pipe heat exchanger. Renewable Energy, 2019, 140: 580–591.

[7] Poongavanam G.K., Ramalingam V., Effect of shot peening on enhancing the heat transfer performance of a tubular heat exchanger. International Journal of Thermal Science, 2019, 139: 1–14.

[8] Poredos P., Suklje T., Medved S., Arkar C., An experimental heat-transfer study for a heat-recovery unit made of corrugated tubes. Applied Thermal Engineering, 2013, 53(1): 49–56.

[9] Hilbert L.R., Bagge-Ravn D., Kold J., Gram L., Influence of surface roughness of stainless steel on microbial adhesion and corrosion resistance. International Biodeterioration & Biodegradation, 2003, 52(3): 175–185.

[10] García S., Trueba A., Vega L.M., Madariaga E., Impact of the surface roughness of AISI 316L stainless steelon biofilm adhesion in a seawater-cooled tubular heat exchanger-condenser. Biofouling, 2016, 32(10): 1185–1193.

[11] Li C., Study on friction and lubrication characteristics of surface with unidirectional convergence texture. Coatings, 2019, 9(12): 780.

[12] Wos S., Koszela W., Dzierwa A., Pawlus P., Friction reduction in unidirectional lubricated sliding due to disc surface texturing. Coatings, 2020, 10: 221.

[13] Petrovi'c S., Laser-assisted surface texturing of Ti/Zr multilayers for mesenchymal stem cell response. Coatings, 2019, 9(12): 854.

[14] Baino F., Montealegre M.A., Minguella-Canela J., Vitale-Brovarone C., Laser surface texturing of alumina/zirconia composite ceramics for potential use in hip joint prosthesis. Coatings, 2019, 9: 369.

[15] Kumar P.G., Heat transfer, pressure drop, and exergy analyses of a shot-peened tube in the tube heat exchanger using Al2O3 nanofluids for solar thermal applications. Powder Technology, 2022, 401: 117299.

[16] Nguyen D.H., SeonAhn H., A comprehensive review on micro/nanoscale surface modification techniques for heat transfer enhancement in heat exchanger. International Journal of Mass Transfer, 2021, 178: 121601.

[17] Koowattanasuchat P., Mahayotsanun N., Sucharitpwatskul S., Mahabunphachai S., Dohda K., Heat transfer enhancement by shot peening of stainless steel. Coatings, 2020, 10: 584.

[18] Goudarzi K., Investigation of the effect of fin configuration and fin angle on thermal performance of finned-tube heat exchanger. experimental study. Thermal Engineering, 2021, 68(7): 556–563.

[19] Jalil E., Goudarzi K., Heat transfer enhancement of finned-tube heat exchanger using nozzle- and diffuser-shaped fins instead of straight fins. Heat Transfer, 2021, 51(2): 1336–1357.

[20] Chibani A., Merouani S., Benmoussa F., Abdellattif MH., Erto A., Jeon B.H., Benguerba Y., A strategy for enhancing heat transfer in phase change material-based latent thermal energy storage unit via nano-oxides addition: A study applied to a shell-and-tube heat exchanger. Journal of Chemical Engineering, 2021, 9(6): 106744.

[21] Tuncer A.D., Sozen A., Khanlari A., Gurbuz E.Y., Variyenli H.I., Upgrading the performance of a new shell and helically coiled heat exchanger by using longitudinal fins. Applied Thermal Engineering, 2021, 191: 116876.

[22] Gugulothu R., Sanke N., Use of segmental baffle in shell and tube heat exchanger for nanoemulsions. Heat transfer, 2022, 51(3): 2645–2666.

[23] Goswami A., Pillai S.C., Mcgranaghan G., Micro/Nanoscale surface modifications to combat heat exchanger fouling. Chemical Engineering Journal Advances, 2023, 16: 100519.

[24] Maurya AK., Khan W.N., Patnaik A., Tribological performance of gas tungsten arc welded dissimilar joint of sDSS 2507/IN-625 for marine application. Archives of Civil and Mechanical Engineering, 2023, 24: 2023.

[25] Adin M.S., A parametric study on the mechanical properties of MIG and TIG welded dissimilar steel joints. Journal Adhesive Science and Technology, 2022, 38(1): 115–138.

[26] Adin M.S., Okums M., Investigation of microstructural and mechanical properties of dissimilar metal weld between AISI 420 and AISI 1018 steels. Arabian Journal for Science and Engineering, 2021, 47: 8341–8350.

[27] Premkumar I., Prabhu I.J., Vijayan A., Antony G.A., Combustion analysis of biodiesel blends with different piston geometries. Journal of Thermal Analysis and Calorimetry, 2020, 142(4): 1457–1467.

[28] David R., Priya C.B., Aruna M., Kaliyaperumal G., Mukilarasan N., Malladi A., Karthikeyan M., Synthesis and experimental thermal adsorption characteristics of epoxy hybrid composite for energy storage applications. Adsorption Science & Technology, 2023, pp. 4817731.

[29] Vijayan V., Vivekanandan M., Rajaguru K., Antony G.A., CFD modelling and analysis of a two-phase vapor separator. Journal of Thermal Analysis and Calorimetry, 2021, 145(5): 2719–2726.

[30] Christraj W., Experimental investigation of multipurpose solar heating system. Journal of Energy Engineering, 2015, 141(3): 04014009.

[31] Raghuvaran S., Vivekanandan M., Kannan C.R., Thirugnanasambandham T., Murugan A., Barik D., Evaluation of thermal adsorption and mechanical behaviour of intralaminar jute/sisal/e-glass fibre-bonded epoxy hybrid composite as an insulator. Adsorption Science & Technology, 2023.