[1] Guan B.W., Zhang T., Liu X.H., On-site performance investigation of a desiccant wheel deep-dehumidification system applied in lithium battery manufacturing plant. Energy and Buildings, 2021, 232: 110659. https://doi.org/10.1016/j.enbuild.2020.110659

[2] Zhang Q.L., Li Y.X., Zhang Q.Y., et al., Application of deep dehumidification technology in low-humidity industry: A review. Renewable and Sustainable Energy Reviews, 2024, 193: 114278. https://doi.org/10.1016/j.rser.2024.114278

[3] Fang S., Xu Z.R., Zhou X., et al., Cascade deep air dehumidification with integrated direct-contact cooling and liquid desiccant absorption. Energy Conversion and Management, 2022, 268: 115959. https://doi.org/10.1016/j.enconman.2022.115959

[4] Guan B.W., Liu X.H., Wang X.K., et al., Regeneration energy analysis on desiccant wheel system in curling arena for the Winter Olympics. Building and Environment, 2022, 214: 108960. https://doi.org/10.1016/j.buildenv.2022.108960

[5] Guan B.W., Zhang T., Liu J., et al., Review of internally cooled liquid desiccant air dehumidification: Materials, components, systems, and performances. Building and Environment, 2022, 211: 108747. https://doi.org/10.1016/j.buildenv.2021.108747

[6] Liu Y.X., Liu Z.L., Xia X.X., et al., Desiccant performance evaluation of desiccant-coated heat exchanger-based heat pump by equilibrium model. Journal of Thermal Science, 2023, 32(6): 2361–2373. https://link.springer.com/article/10.1007/s11630-023-1881-0

[7] Zheng X., Lu Y., Wang B., et al., Experimental and theoretical study of an internally cooled liquid desiccant dehumidifier. Journal of Thermal Science, 2023, 32(4): 1684–1696. https://doi.org/10.1007/s11630-023-1725-y

[8] Xu C., Sui J., Dai Y.Z., et al., Performance analysis of a combined absorption refrigeration-liquid desiccant dehumidification THIC system driven by low-grade heat source. Journal of Thermal Science, 2020, 29: 1193–1205. https://doi.org/10.1007/s11630-020-1363-6

[9] Pan L.S., Shi W.X., Li B., et al., Experimental investigation on the performance of [APMIm][NTf2] for capturing CO2 from flue gas of the cement kiln tail. Journal of Thermal Science, 2021, 30(5): 1780–1788. https://doi.org/10.1007/s11630-021-1504-6

[10] Liu X.L., Qu M., Liu X.B., et al., Numerical modeling and performance analysis of a membrane-based air dehumidifier using ionic liquid desiccant. Applied Thermal Engineering, 2020, 175: 115395. https://doi.org/10.1016/j.applthermaleng.2020.115395

[11] Wang T., Liu X.Y., Xue S., et al., Tuning the Molecular Structure and Transport Property of [bmim][Tf2N] Using Electric Field. Journal of Thermal Science, 2022, 31(4): 1076–1083. https://link.springer.com/article/10.1007/s11630-022-1648-z

[12] Zegenhagen M.T., Kühn R., Meyer T., et al., Investigation of a liquid desiccant system for air dehumidification working with an ionic liquid in a two-stage refrigeration system for cold stores. Proceedings of the 24th IIR International Congress of Refrigeration, Yokohama, Japan, 2015. http://dx.doi.org/10.18462/iir.icr.2015.0860

[13] Varela R.J., Giannetti N., Saito K., et al., Experimental performance of a three-fluid desiccant contactor using a novel ionic liquid. Applied Thermal Engineering, 2022, 210: 118343. https://doi.org/10.1016/j.applthermaleng.2022.118343

[14] Cao B.W., Yin Y.G., Zhang F., et al., Experimental study on heat and mass transfer characteristics between a novel ionic liquid and air under low-humidity conditions. International Journal of Heat and Mass Transfer, 2022, 198: 123373. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123373

[15] Cao B.W., Yin Y.G., Zhang F., et al., Liquid desiccant-based deep dehumidifier working with a novel ionic liquid: Prediction model and performance comparison. International Journal of Refrigeration, 2023, 146: 74–87. https://doi.org/10.1016/j.ijrefrig.2022.09.033

[16] Bhati A., Kar A., Bahadur V., Analysis of CO2 hydrate formation from flue gas mixtures in a bubble column reactor. Separation and Purification Technology, 2024, 330: 125261. https://doi.org/10.1016/j.seppur.2023.125261

[17] Bose A., O'Shea R., Lin R.C., et al., Optimisation and performance prediction of photosynthetic biogas upgrading using a bubble column. Chemical Engineering Journal, 2022, 437: 134988. https://doi.org/10.1016/j.cej.2022.134988

[18] Ensafjoee K., Daghigh R., An evacuated tube solar bubble column liquid desiccant regenerator. Applied Thermal Engineering, 2023, 235: 121331. https://doi.org/10.1016/j.applthermaleng.2023.121331

[19] Zhang X., Dong H.F., Huang Y., et al., Experimental study on gas holdup and bubble behavior in carbon capture systems with ionic liquid. Chemical Engineering Journal, 2012, 209: 607–615. https://doi.org/10.1016/j.cej.2012.08.047

[20] Abro M., Yu L., Yu G.R., et al., Experimental investigation of hydrodynamic parameters and bubble characteristics in CO2 absorption column using pure ionic liquid and binary mixtures: Effect of porous sparger and operating conditions. Chemical Engineering Science, 2021, 229: 116041. https://doi.org/10.1016/j.ces.2020.116041

[21] Yang B.B., Shang D.W., Tu W.H., et al., Studies on the physical properties variations of protic ionic liquid during NH3 absorption. Journal of Molecular Liquids, 2019, 296: 111791. https://doi.org/10.1016/j.molliq.2019.111791

[22] Meng F.Z., Ju T.Y., Han S.Y., et al., Study on the effectiveness of ionic liquid-based biphasic amine solvent in removing H2S, NH3 and CO2 from biogas and its influential characteristics. Chemical Engineering Journal, 2023, 474: 145805. https://doi.org/10.1016/j.cej.2023.145805

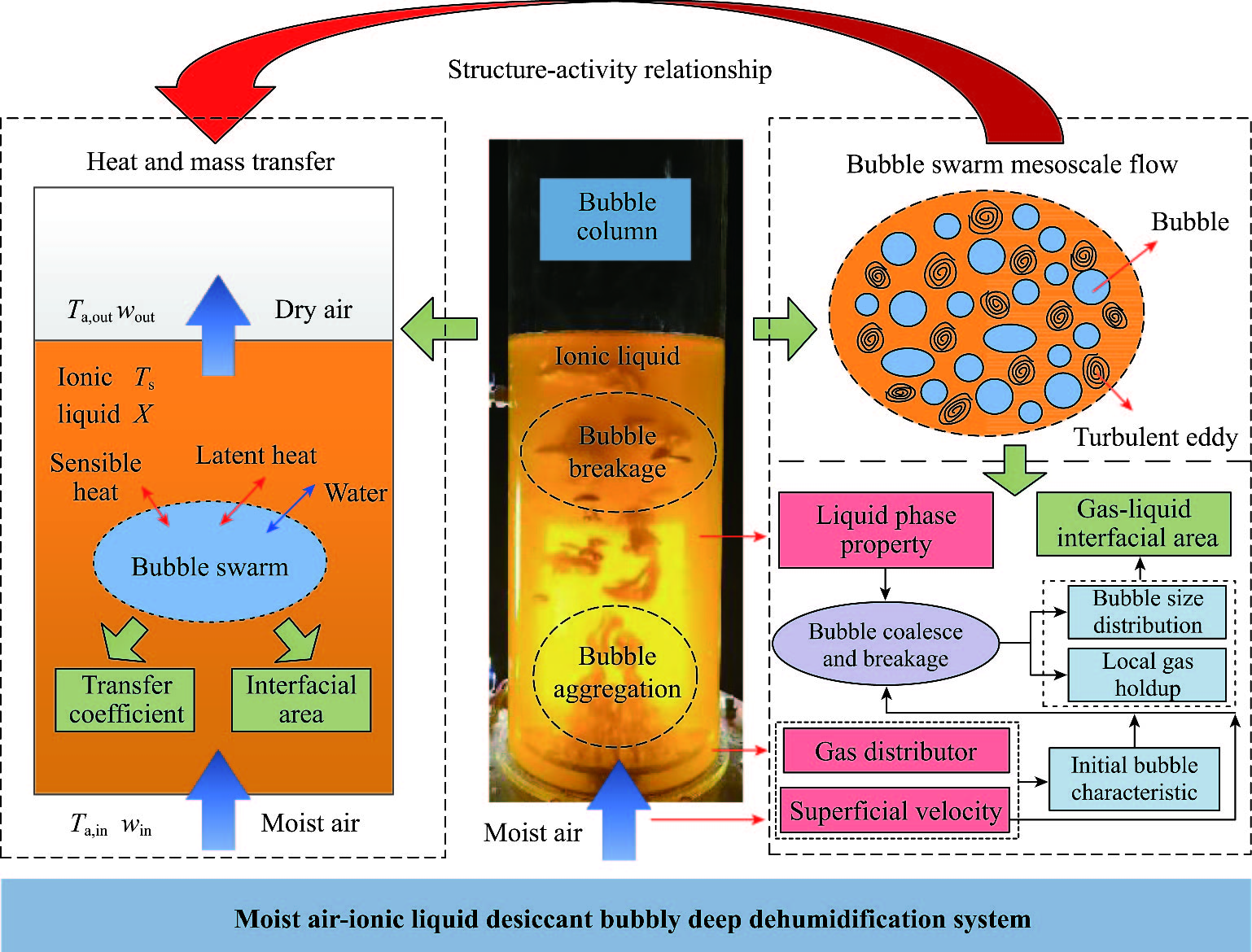

[23] Cao B.W., Yin Y.G., Xu G.Y., et al., A proposed method of bubble absorption-based deep dehumidification using the ionic liquid for low-humidity industrial environments with experimental performance. Applied Energy, 2023, 348: 121534. https://doi.org/10.1016/j.apenergy.2023.121534

[24] Kantarci N., Borak F., Ulgen K.O., Bubble column reactors. Process Biochemistry, 2005, 40(7): 2263–2283. https://doi.org/10.1016/j.procbio.2004.10.004

[25] Wang X.L., Dong H.F., Zhang X.P., et al., Numerical simulation of single bubble motion in ionic liquids. Chemical Engineering Science, 2010, 65(22): 6036–6047. https://doi.org/10.1016/j.ces.2010.08.030

[26] Ali M.F., Gan J.Q., Chen X.C., et al., Hydrodynamic modeling of ionic liquids and conventional amine solvents in bubble column. Chemical Engineering Research and Design, 2018, 129: 356–375. https://doi.org/10.1016/j.cherd.2017.11.034

[27] Zhang X., Zhang S.J., Bao D., et al., Absorption degree analysis on biogas separation with ionic liquid systems. Bioresource Technology, 2015, 175: 135–141. https://doi.org/10.1016/j.biortech.2014.10.048

[28] Bao D., Zhang X., Dong H.F., et al., Numerical simulations of bubble behavior and mass transfer in CO2 capture system with ionic liquids. Chemical Engineering Science, 2015, 135: 76–88. https://doi.org/10.1016/j.ces.2015.06.035

[29] Cao B.W., Yin Y.G., Xu G.Y., et al., Experimental and modeling study of bubble absorption-based deep dehumidification using the ionic liquid: Parametric analysis on heat and mass transfer. Energy Conversion and Management, 2023, 290: 117169. https://doi.org/10.1016/j.enconman.2023.117169

[30] Eder E., Hiller S., Brüggemann D., et al., Characteristics of air-liquid heat and mass transfer in a bubble column humidifier. Applied Thermal Engineering, 2022, 209: 118240. https://doi.org/10.1016/j.applthermaleng.2022.118240

[31] He Y.R., Ren A.X., Tang T.Q., et al., Multi-scale numerical simulation of flow, heat and mass transfer behaviors in dense gas-solid flows: A brief review. Journal of Thermal Science, 2022, 31(3): 607–633. https://link.springer.com/article/10.1007/s11630-022-1605-x

[32] Li J.H., Approaching virtual process engineering with exploring mesoscience. Chemical Engineering Journal, 2015, 278: 541–555.

https://doi.org/10.1016/j.cej.2014.10.005

[33] Dong K., Liu X.M., Dong H.F., et al., Multiscale studies on ionic liquids. Chemical Reviews, 2017, 117(10): 6636–6695. https://doi.org/10.1021/acs.chemrev.6b00776

[34] Lun W., Li K.N., Liu B., et al., Experimental analysis of a novel internally-cooled dehumidifier with self-cooled liquid desiccant. Building and Environment, 2018, 141: 117–126. https://doi.org/10.1016/j.buildenv.2018.05.055

[35] Cappelli D., Glennon B., Donnellan P., CFD Simulation of a bubble column evaporator. International Journal of Heat and Mass Transfer, 2022, 188: 122296. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122296

[36] Zhang H.H., Guo K.Y., Wang Y.L., et al., Numerical simulations of the effect of liquid viscosity on gas-liquid mass transfer of a bubble column with a CFD-PBM coupled model. International Journal of Heat and Mass Transfer, 2020, 161: 120229. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120229

[37] Wang T.F., Wang J.F., Jin Y., A CFD-PBM coupled model for gas–liquid flows. AIChE Journal, 2006, 52(1): 125–140. https://doi.org/10.1002/aic.10611

[38] Luo H., Svendsen H.F., Theoretical model for drop and bubble breakup in turbulent dispersions. AIChE Journal, 1996, 42(5) 1225–1233. https://doi.org/10.1002/aic.690420505

[39] Luo H., Coalescence, breakup and liquid circulation in bubble column reactors. PhD thesis from the Norwegian Institute of Technology. Trondheim, Norway, 1993. https://elibrary.ru/item.asp?id=6864276

[40] Li C.X., Cui Y.Z., Shi X.G., et al., CFD simulation of mass transfer in bubble columns: Detailed study of mass transfer models. Chemical Engineering Science, 2022, 264: 118173. https://doi.org/10.1016/j.ces.2022.118173

[41] Verma A.K., Rai S., Studies on surface to bulk ionic mass transfer in bubble column, Chemical Engineering Journal. 2003, 94(1): 67–72. https://doi.org/10.1016/S1385-8947(03)00047-0

[42] Behkish A., Men Z.W., Inga J.R., et al., Mass transfer characteristics in a large-scale slurry bubble column reactor with organic liquid mixtures. Chemical Engineering Science, 2002, 57(16): 3307–3324. https://doi.org/10.1016/S0009-2509(02)00201-4

[43] Pakari A., Ghani S., Performance comparison of different flow arrangements of 4-fuid internally-cooled liquid desiccant dehumidifers. Journal of Thermal Analysis and Calorimetry, 2022, 147(19): 10439–10459. https://doi.org/10.1007/s10973-022-11283-x

[44] Yin Y.G., Chen T.T., Zhang X.S., Heat and mass transfer performance evaluation and advanced liquid desiccant air-conditioning systems. Desiccant Heating, Ventilating, and Air-Conditioning Systems, 2017, pp. 133–165. https://doi.org/10.1007/978-981-10-3047-5_6

[45] Panigrahi B., Wang H.W., Luo W.J., et al., Comparative analysis of the static and dynamic dehumidification performance of metal-organic framework materials. Science and Technology for the Built Environment, 2023, 29(3): 323–338. https://doi.org/10.1080/23744731.2023.2170682

[46] Panigrahi B., Chen Y.S., Luo W.J., et al., Dehumidification effect of polymeric superabsorbent SAP-LiCl composite desiccant-coated heat exchanger with different cyclic switching time. Sustainability, 2020, 12(22): 9673. https://www.mdpi.com/2071-1050/12/22/9673