[1] Angelino G., Carbon dioxide condensation cycles for power production. Journal of Engineering for Power, 1968, 90(3): 287–295.

[2] Feher E.G., The supercritical thermodynamic power cycle. Energy Conversion, 1968, 8(2): 85–90.

[3] Liu Y., Wang Y., Huang D., Supercritical CO2 Brayton cycle: A state-of-the-art review. Energy, 2019, 189: 115900.

[4] Zhang R., Su W., Lin X., Zhou N., Zhao L., Thermodynamic analysis and parametric optimization of a novel S-CO2 power cycle for the waste heat recovery of internal combustion engines. Energy, 2020, 209: 118484.

[5] Persichilli M., Kacludis A., Zdankiewicz E., Held T., Supercritical CO2 power cycle developments and commercialization: why SCO2 can displace steam. Power-Gen India & Central Asia, 2012.

[6] Pecnik R., Rinaldi E., Colonna P., Computational fluid dynamics of a radial compressor operating with supercritical CO2. Journal of Engineering for Gas Turbines and Power, 2012, 134(12): 122301.

[7] Yang J., Yang Z., Duan Y., Design optimization and operating performance of S-CO2 Brayton cycle under fluctuating ambient temperature and diverse power demand scenarios. Journal of Thermal Science, 2024, 33(1): 190–206.

[8] Yang Z., Jiang H., Zhuge W., Cai R., Yang M., Chen H., Zhang Y., Flow loss mechanism in a supercritical carbon dioxide centrifugal compressor at low flow rate conditions. Journal of Thermal Science, 2024, 33(1): 114–125.

[9] Baltadjiev N.D., Lettieri C., Spakovszky Z.S., An investigation of real gas effects in supercritical CO2 centrifugal compressors. Journal of Turbomachinery, 2015, 137(9): 091003.

[10] Kim S.G., Lee J., Ahn Y., Lee J.I., Addad Y., Ko B., CFD investigation of a centrifugal compressor derived from pump technology for supercritical carbon dioxide as a working fluid. The Journal of Supercritical Fluids, 2014, 86: 160–171.

[11] Saravi S., Tassou S., An investigation into sCO2 compressor performance prediction in the supercritical region for power systems. Energy Procedia, 2019, 161: 403–411.

[12] Karaefe R.E., Post P., Sembritzky M., Numerical investigation of a centrifugal compressor for supercritical CO2 cycles. In: Proceedings of the ASME Turbo Expo 2020: Power for Land, Sea, and Air, online, 2020, September 21–25, Paper No: GT2020-15194, V011T31A011.

[13] Lee J., Lee J.I., Ahn Y., Yoon H., Design methodology of supercritical CO2 Brayton cycle turbomachineries. In: Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 2012, June 11–15, Paper No: GT2012-68933, pp. 975–983.

[14] Monje B., Sánchez D., Savill M., Pilidis P., Sánchez T., A design strategy for supercritical CO2 compressors. In: Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 2014, June 16–20, Paper No: GT2014-25151, V03BT36A003.

[15] Ameli A., Afzalifar A., Turunen-Saaresti T., Backman J., Centrifugal compressor design for near-critical point applications. Journal of Engineering for Gas Turbines and Power, 2019, 141(3): 031016.

[16] Cho S.K., Bae S.J., Jeong Y., Lee J., Lee J.I., Direction for high-performance supercritical CO2 centrifugal compressor design for dry cooled supercritical CO2 Brayton cycle. Applied Sciences, 2019, 9(19): 4057.

[17] Jeong Y., Son S., Cho S. K., Evaluation of supercritical CO2 compressor off-design performance prediction methods. Energy, 2020, 213: 119071

[18] Cho, S.K., Son S., Lee J., Lee S.W., Jeong Y., Oh B.S., Lee J.I., Optimum loss models for performance prediction of supercritical CO2 centrifugal compressor. Applied Thermal Engineering, 2021, 184: 116255.

[19] Xia W., Zhang Y., Yu H., Han Z., Dai Y., Aerodynamic design and multi-dimensional performance optimization of supercritical CO2 centrifugal compressor. Energy Conversion and Management, 2021, 248: 114810.

[20] Xu P., Zou Z., Fu C., Aerodynamic design considerations for supercritical CO2 centrifugal compressor with real-gas effects. Energy Conversion and Management, 2022, 271: 116318.

[21] Denton J.D., Loss mechanisms in turbomachines. Proceedings of the ASME 1993 International Gas Turbine and Aeroengine Congress and Exposition, Ohio, USA, 1993, May 24–27, Paper No: 93-GT-435, V002T14A001.

[22] Sundström E., Kerres B., Sanz S., Mihăescu M., On the assessment of centrifugal compressor performance parameters by theoretical and computational models. In: Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, North Carolina, USA, 2017, June 26–30, Paper No: GT2017-65230, V02CT44A029.

[23] Wright S.A., Radel R.F., Vernon M.E., Rochau G.E., Pickard P.S., Operation and analysis of a supercritical CO2 Brayton cycle. Sandia Report, No. SAND2010-0171, 2010.

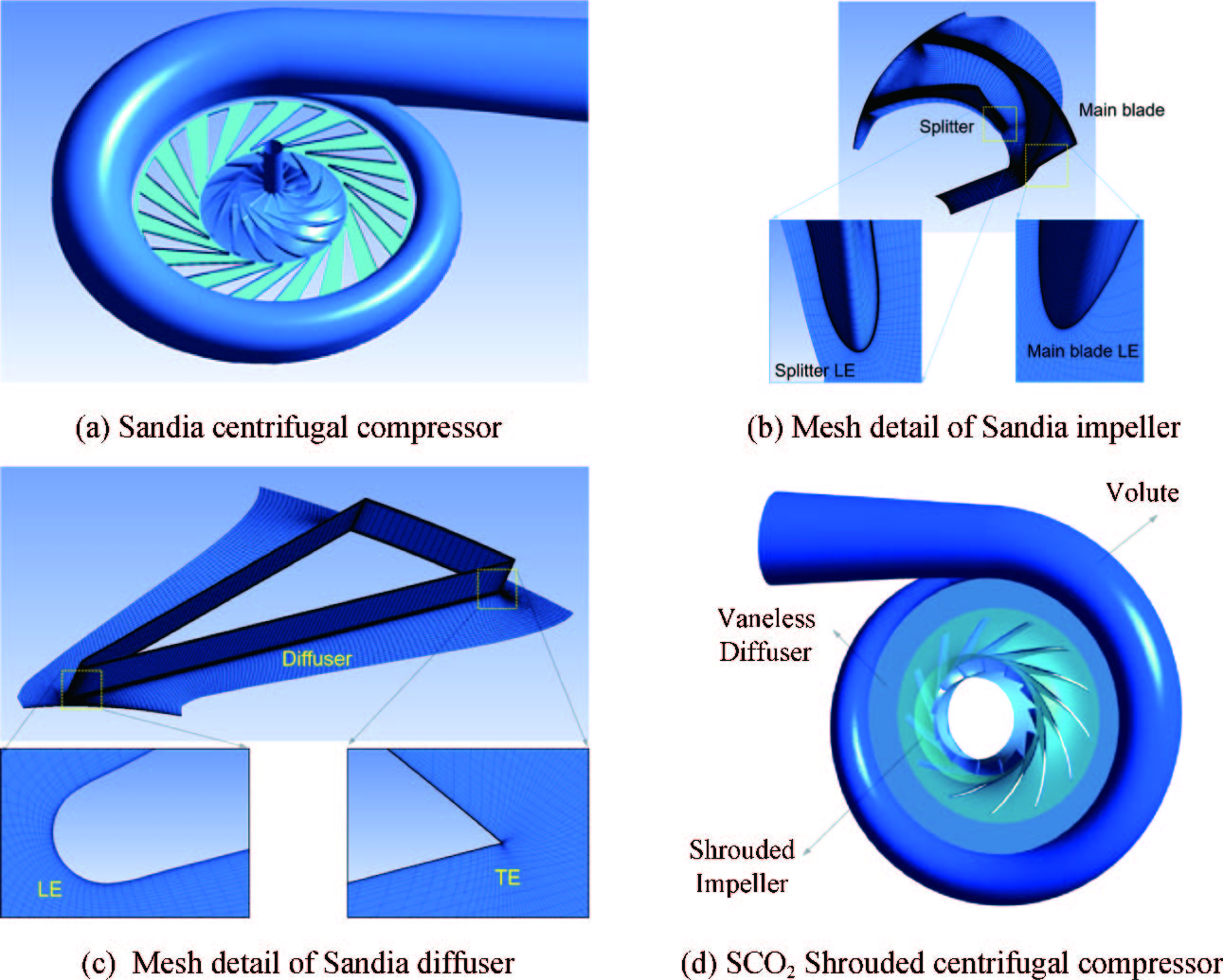

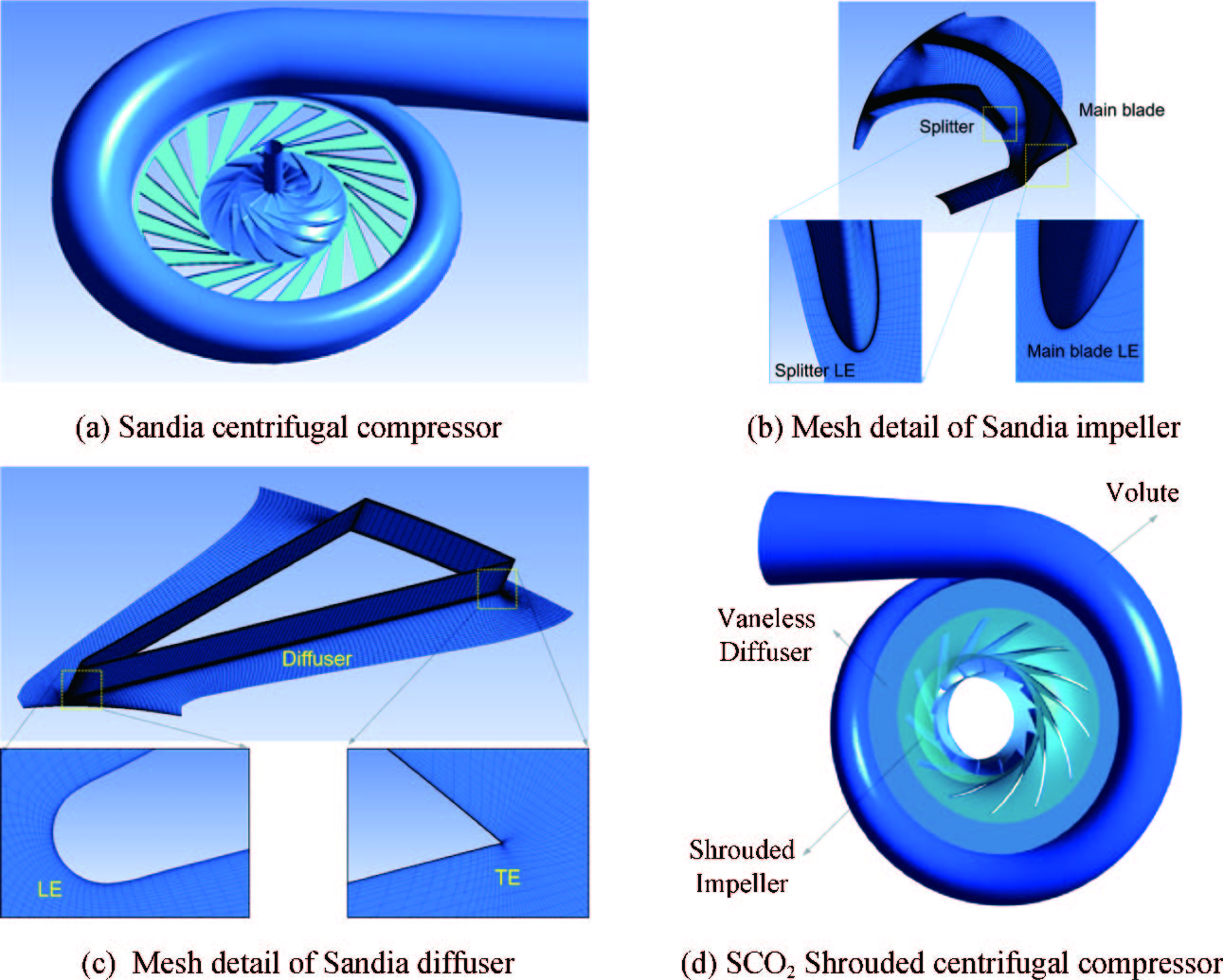

[24] Rinaldi E., Pecnik R., Colonna P., Steady state CFD investigation of a radial compressor operating with supercritical CO2. In: Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, Texas, USA, 2013, June 3–7, Paper No: GT2013-94580, V008T34A008.

[25] Patel A., Diez R., Pecnik R., Turbulence modelling for flows with strong variations in thermo-physical properties. International Journal of Heat and Fluid Flow, 2018, 73: 114–123.

[26] Anand N., Vitale S., Pini M., Otero G.J., Pecnik R., Design methodology for supersonic radial vanes operating in nonideal flow conditions. Journal of Engineering for Gas Turbines and Power, 2019, 141(2): 022601.

[27] Rinaldi E., Pecnik R., Colonna P., Unsteady operation of a highly supersonic organic rankine cycle turbine. Journal of Turbomachinery, 2016, 138(12): 121010.

[28] Wheeler A. P., Ong J., A study of the three-dimensional unsteady real gas flows within a transonic ORC turbine. In ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Wind Energy. Düsseldorf, Germany. June 16–20, 2014. Paper No: GT2014-25475, V03BT26A003.

[29] Shao W., Yang J., Wang X., Ma Z., Accuracy study and stability control of a property-table-based CFD strategy for modeling SCO2 compressors working near the critical point of the fluid. Applied Thermal Engineering, 2021, 183: 116222.

[30] Lemmon E., Huber M., McLinden M., NIST Standard Reference Database 23, NIST Reference Fluid Thermodynamic and Transport Properties Database (REFPROP): Version 9.1. National Institute of Standards and Technology, 2007.

[31] Ameli A., Afzalifar A., Turunen-Saaresti T., Backman J., Effects of real gas model accuracy and operating conditions on supercritical CO2 compressor performance and flow field. Journal of Engineering for Gas Turbines and Power, 2018, 140(6): 062603.

[32] Greitzer E.M., Tan C.S., Graf M.B., Internal flow concept and applications, Cambridge University Press, 2004.

[33] Patel A., Boersma B.J., Pecnik R., The influence of near-wall density and viscosity gradients on turbulence in channel flows. Journal of Fluid Mechanics, 2016, 809: 793–820.

[34] Japikse D., Centrifugal compressor design and performance. Concepts Eti, 1996.