[1] Xie G., Xu X., Lei X., et al., Heat transfer behaviors of some supercritical fluids: A review. Chinese Journal of Aeronautics, 2022, 35(1): 290–306.

[2] Ahn Y., Bae S.J., Kim M., et al., Review of supercritical CO2 power cycle technology and current status of research and development. Nuclear Engineering and Technology, 2015, 47(6): 647–661.

[3] Binotti M., Astolfi M., Campanari S., et al., Preliminary assessment of sCO2 cycles for power generation in CSP solar tower plants. Applied Energy, 2017, 204: 1007–1017.

[4] Song J., Wang Y., Wang K., et al., Combined supercritical CO2 (SCO2) cycle and organic Rankine cycle (ORC) system for hybrid solar and geothermal power generation: Thermoeconomic assessment of various configurations. Renewable Energy, 2021, 174: 1020–1035.

[5] Zhang X.R., Yamaguchi H., Fujima K., et al., Theoretical analysis of a thermodynamic cycle for power and heat production using supercritical carbon dioxide. Energy, 2007, 32(4): 591–599.

[6] Wu P., Ma Y., Gao C., et al., A review of research and development of supercritical carbon dioxide Brayton cycle technology in nuclear engineering applications. Nuclear Engineering and Design, 2020, 368: 110767.

[7] Li Z., Shi M., Shao Y., et al., Supercritical CO2 cycles for nuclear-powered marine propulsion: preliminary conceptual design and off-design performance assessment. Journal of Thermal Science, 2024, 33(1): 328–347.

[8] Qin L., Xie G., Ma Y., et al., Thermodynamic analysis and multi-objective optimization of a waste heat recovery system with a combined supercritical/transcritical CO2 cycle. Energy, 2023, 265: 126332.

[9] Feng F., Li T., An J., et al., Performance assessment of a novel polygeneration system based on the integration of waste plasma gasification, tire pyrolysis, gas turbine, supercritical CO2 cycle and organic Rankine cycle. Journal of Thermal Science, 2023, 32(6): 2196–2214.

[10] Fairuz Z.M., Jahn I., Abdul-Rahman R., The effect of convection area on the deformation of dry gas seal operating with supercritical CO2. Tribology International, 2019, 137: 349–365.

[11] Yuan T., Yang R., Li Z., et al., Thermal characteristics and cooling effect for SCO2 dry gas seal with multiple dynamic groove types. Applied Thermal Engineering, 2024, 236: 121896.

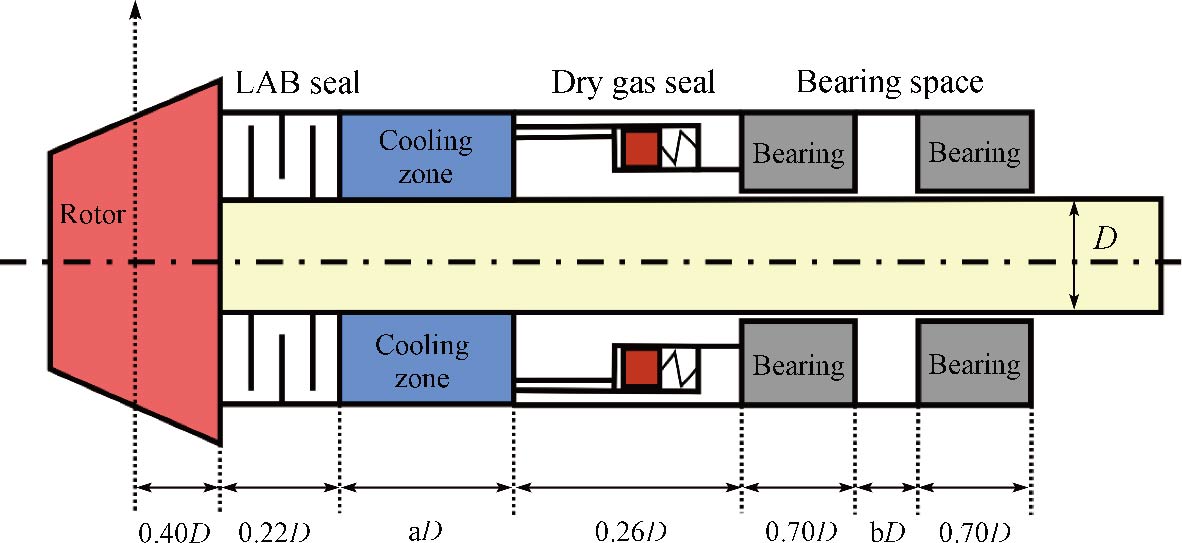

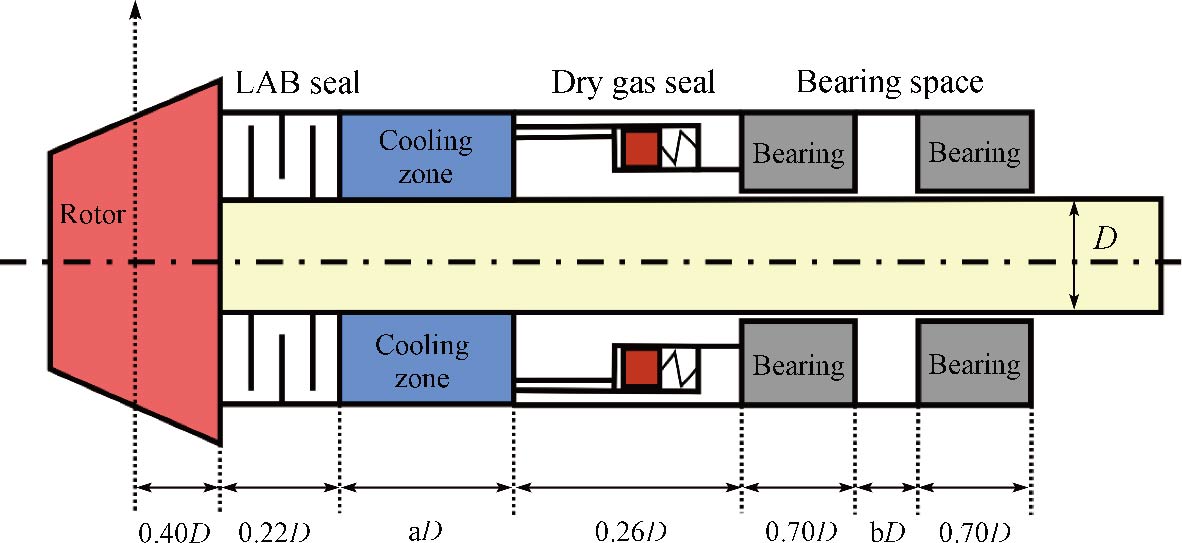

[12] Uddin M., Gurgenci H., Guan Z., et al., Design a cooling pillow to support a high-speed supercritical CO2 turbine shaft. Applied Thermal Engineering, 2021, 196: 117345.

[13] Peeters J.W.R., T’Joen C., Rohde M., Investigation of the thermal development length in annular upward heated laminar supercritical fluid flows. International Journal of Heat and Mass Transfer, 2013, 61: 667–674.

[14] Peeters J.W.R., Pecnik R., Rohde M., et al., Characteristics of turbulent heat transfer in an annulus at supercritical pressure. Physical Review Fluids, 2017, 2(2): 024602.

[15] Qin K., Li D., Huang C., et al., Numerical investigation on heat transfer characteristics of Taylor Couette flows operating with CO2. Applied Thermal Engineering, 2020, 165: 114570.

[16] Uddin M., Gurgenci H., Klimenko A., et al., Heat transfer analysis of supercritical CO2 in a high-speed turbine rotor shaft cooling passage. Thermal Science and Engineering Progress, 2023, 39: 101694.

[17] Xiao Y., Pan J., Gu H., Numerical investigation of spacer effects on heat transfer of supercritical fluid flow in an annular channel. International Journal of Heat and Mass Transfer, 2018, 121: 343–353.

[18] Eze C., Wong K.W., Gschnaidtne T., et al., Numerical study of effects of vortex generators on heat transfer deterioration of supercritical water upward flow. International Journal of Heat and Mass Transfer, 2019, 137: 489–505.

[19] Eze C., Lau K.T., Ahmad S., et al., Mitigation of heat transfer deterioration in a circular tube with supercritical CO2 using a novel small-scale multiple vortex generator. International Journal of Thermal Sciences, 2020, 156: 106481.

[20] Gond A.K., Basu D.N., Dalal A., Numerical investigation of heat transfer characteristics of CO2 in a vertical divergent tapered annular channel. Fluid Mechanics and Fluid Power, 2024, 1: 483–493.

[21] Wong K.W., Cheng H., Zhao J., Numerical study on mitigation of heat transfer deterioration in supercritical CO2 heat exchanger application. 25th International Conference on Nuclear Engineering, Shanghai, China, 2017, 6: V006T08A104.

DOI: https://doi.org/10.1115/ICONE25-67612.

[22] Yuan H., Edlebeck J., Wolf M., et al., Simulation of supercritical CO2 flow through circular and annular orifice. Journal of Nuclear Engineering and Radiation Science, 2015, 1(2): 021003.

[23] Xi L., Gao J., Xu L., et al., Study on heat transfer performance of steam-cooled ribbed channel using neural networks and genetic algorithms. International Journal of Heat and Mass Transfer, 2018, 127: 1110–1123.

[24] Xi L., Xu L., Gao J., et al., Numerical analysis and optimization on flow and heat transfer performance of a steam-cooled ribbed channel. Case Studies in Thermal Engineering, 2021, 28: 101442.

[25] Zhang G., Sundén B., Xie G., Combined experimental and numerical investigations on heat transfer augmentation in truncated ribbed channels designed by adopting fractal theory. International Communications in Heat and Mass Transfer, 2021, 121: 105080.

[26] El Maakoul A., Feddi K., Saadeddine S., et al., Performance enhancement of finned annulus using surface interruptions in double-pipe heat exchangers. Energy Conversion and Management, 2020, 210: 112710.

[27] Wang J., Guan Z., Gurgenci H., et al., A comprehensive review on numerical approaches to simulate heat transfer of turbulent supercritical CO2 flows. Numerical Heat Transfer, Part B: Fundamentals, 2020, 77(5): 349–400.

[28] Kim H.Y., Kim H.R., Kang D.J., et al., Experimental investigations on heat transfer to CO2 flowing upward in a narrow annulus at supercritical pressures. Nuclear Engineering and Technology, 2008, 40(2): 155–162.

[29] Li Y., Sun F., Xie G., et al., Improved thermal performance of cooling channels with truncated ribs for a scramjet combustor fueled by endothermic hydrocarbon. Applied Thermal Engineering, 2018, 142: 695–708.

[30] Li X., Meng J., Li Z., Roughness enhanced mechanism for turbulent convective heat transfer. International Journal of Heat and Mass Transfer, 2011, 54(9–10): 1775–1781.

[31] Wang Z., Guo Q., Wu Y., et al., Frictional resistance investigation of sCO2 and a semi-empirical friction factor correlation based on wall-of-the-law. International Journal of Heat and Mass Transfer, 2023, 217: 124634.

[32] Jing Q., Xie Y., Zhang D., Thermal hydraulic performance of printed circuit heat exchanger with various channel configurations and arc ribs for SCO2 Brayton cycle. International Journal of Heat and Mass Transfer, 2020, 150: 119272.