[1] Bunker R.S., Film cooling: Breaking the limits of diffusion shaped holes, TURBINE-09. Proceedings of International Symposium on Heat Transfer in Gas Turbine Systems, 2009.

[2] Gupta S., Chaube A., Verma P., Review on heat transfer augmentation techniques: application in gas turbine blade internal cooling. Journal of Engineering Science & Technology Review, 2012, 5(1): 57–62.

[3] Ke Z., Wang J., Conjugate heat transfer simulations of pulsed film cooling on an entire turbine vane. Applied Thermal Engineering, 2016, 109: 600–609.

[4] Wang Z., Wang D., Wang Z., et al., Heat transfer analyses of film-cooled HP turbine vane considering effects of swirl and hot streak. Applied Thermal Engineering, 2018, 142: 815–829.

[5] Kang Y.S., Rhee D.H., Lee S., et al., Conjugate heat transfer analysis to assess overall cooling effectiveness of high pressure turbine nozzle with optimized film cooling hole arrangements. Turbo Expo: Power for Land, Sea, and Air, American Society of Mechanical Engineers, 2019, 58646: V05AT10A008.

[6] Zhou W.L., Deng Q., He W., et al., Conjugate heat transfer analysis for composite cooling structure using a decoupled method. International Journal of Heat and Mass Transfer, 2020, 149: 119200.

[7] Shen Z., Xie Y., Zhang D., Numerical predictions on fluid flow and heat transfer in U-shaped channel with the combination of ribs, dimples and protrusions under rotational effects. International Journal of Heat and Mass Transfer, 2015, 80: 494–512.

[8] Rao Y., Chen P., Wan C., Experimental and numerical investigation of impingement heat transfer on the surface with micro W-shaped ribs. International Journal of Heat and Mass Transfer, 2016, 93: 683–694.

[9] Zhou J., Wang X., Li J., Influences of effusion hole diameter on impingement/effusion cooling performance at turbine blade leading edge. International Journal of Heat and Mass Transfer, 2019, 134: 1101–1118.

[10] Chang S.W., Liou H.F., Heat transfer of impinging jet-array onto concave-and convex-dimpled surfaces with effusion. International Journal of Heat and Mass Transfer, 2009, 52: 4484–4499.

[11] Hong S.K., Lee D.H., Cho H.H., Heat/mass transfer in rotating impingement/effusion cooling with rib turbulators. International Journal of Heat and Mass Transfer, 2009, 52: 3109–3117.

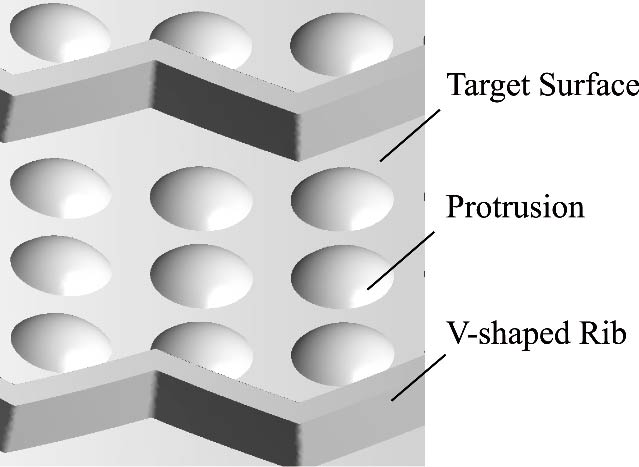

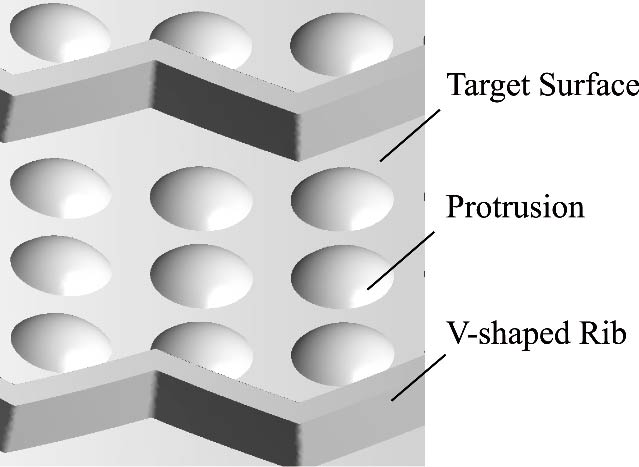

[12] Jing Q., Zhang D., Xie Y., Numerical investigations of impingement cooling performance on flat and non-flat targets with dimple/protrusion and triangular rib. International Journal of Heat and Mass Transfer, 2018, 126: 169–190.

[13] Cornaro C., Fleischer A.S., Goldstein R.J., Flow visualization of a round jet impinging on cylindrical surfaces. Experimental Thermal and Fluid Science, 1999, 20(2): 66–78.

[14] Rhee D.H., Nam Y.W., Cho H.H., Local heat/mass transfer with various rib arrangements in impingement/effusion cooling system with crossflow. Journal of Turbomachinery, 2004, 126(4): 615–626.

[15] Rao Y., Chen P., Wan C., Experimental and numerical investigation of impingement heat transfer on the surface with micro W-shaped ribs. International Journal of Heat and Mass Transfer, 2016, 93: 683–694.

[16] Lamont J.A., Ekkad S.V., Anne Alvin M., Effect of rotation on detailed heat transfer distribution for various rib geometries in developing channel flow. Journal of Heat Transfer, 2014, 136(1): 011901.

[17] Kumar A., Kim M.H., Thermohydraulic performance of rectangular ducts with different multiple V-rib roughness shapes: A comprehensive review and comparative study. Renewable and Sustainable Energy Reviews, 2016, 54: 635–652.

[18] Wright L.M., Fu W.L., Han J.C., Thermal performance of angled, V-shaped, and W-shaped rib turbulators in rotating rectangular cooling channels (AR=4: 1), Turbo Expo: Power for Land, Sea, and Air, 2004, 41685: 885–894.

[19] Ravi R.K., Saini R.P., Experimental investigation on performance of a double pass artificial roughened solar air heater duct having roughness elements of the combination of discrete multi V shaped and staggered ribs. Energy, 2016, 116: 507–516.

[20] Ekkad S.V., Huang Y., Han J.C., Detailed heat transfer distributions in two-pass square channels with rib turbulators and bleed holes. International Journal of Heat and Mass Transfer, 1998, 41(23): 3781–3791.

[21] Fu W.L., Wright L.M., Han J.C., Heat transfer in two-pass rotating rectangular channels (AR=2: 1) with discrete ribs. Journal of Thermophysics and Heat Transfer, 2006, 20(3): 569–582.

[22] Chen Y., Chew Y.T., Khoo B.C., Heat transfer and flow structure in turbulent channel flow over protrusions. International Journal of Heat and Mass Transfer, 2013, 66: 177–191.

[23] Du W., Luo L., Wang S., et al., Flow structure and heat transfer characteristics in a 90-deg turned pin fined duct with different dimple/protrusion depths. Applied Thermal Engineering, 2019, 146: 826–842.

[24] Kim J.E., Doo J.H., Ha M.Y., et al., Numerical study on characteristics of flow and heat transfer in a cooling passage with protrusion-in-dimple surface. International Journal of Heat and Mass Transfer, 2012, 55: 7257–7267.

[25] Kaur I., Singh P., Ekkad S.V., Enhanced thermal hydraulic performance by V-shaped protrusion for gas turbine blade trailing edge cooling. International Journal of Heat and Mass Transfer, 2020, 149: 119221.

[26] Xie Y., Qu H., Zhang D., Numerical investigation of flow and heat transfer in rectangular channel with teardrop dimple/protrusion. International Journal of Heat and Mass Transfer, 2015, 84: 486–496.

[27] Wang M.R., Zhu H.R., Liu C.L., et al., Numerical analysis and design optimization on full coverage film-cooling for turbine guided vane. Engineering Applications of Computational Fluid Mechanics, 2022, 16(1): 904–936.

[28] Wang M.R., Zhu H.R., Liu C.L., et al., Numerical investigation of flow and heat transfer in vane impingement/effusion cooling with various rib/dimple structure. Journal of Thermal Science, 2023, 32(4): 1357–1377.

[29] Wang M.R., Zhu H.R., Liu C.L., et al., Structure improvement on turbine guided vane cooling system based on conjugate heat transfer. International Journal of Thermal Sciences, 2022, 172: 107332.

[30] Huang Y., Zhang J., Wang C., Shape-optimization of round-to-slot holes for improving film cooling effectiveness on a flat surface. Heat and Mass Transfer, 2018, 54(6): 1741–1754.

[31] Andrews G.E., Asere A.A., Mkpadi M.C., et al., Transpiration cooling: contribution of film cooling to the overall cooling effectiveness. International Journal of Turbo and Jet Engines, 1986, 3(2–3): 245–256.