气膜冷却是涡轮叶片热防护的关键技术,然而在保持结构完整性与制造便利性的同时开发高性能气膜冷却结构仍是一大挑战。相较于传统异形孔,锯齿槽-孔设计能提升冷气覆盖范围并具有更好的制造便利性,但其在不同流向压力梯度下的性能尚未得到系统研究。本研究通过与传统圆柱孔对比,探究了主流流向压力梯度(零梯度、逆压梯度与顺压梯度)对锯齿槽-孔气膜冷却特性的影响。研究结合实验测量与大涡模拟(LES)方法,分析了不同压力梯度及吹风比(M=0.5与M=1.5)条件下的流动动力学与气膜冷却性能。实验结果表明:锯齿槽-孔结构能持续提升气膜冷却效率;在逆压梯度条件下,该结构可抑制冷却效率的衰减,并同时改善流向与展向覆盖范围。尤其在M=1.5时,锯齿槽-孔使出口附近气膜冷却效率较圆柱孔提升约2–3倍。在顺压梯度条件下,锯齿槽-孔通过促进气膜的展向连续性与流向扩展进一步优化冷却效果,出口附近最大气膜冷却效率可达约0.9。与零压梯度工况相比,顺压梯度使锯齿槽-孔的展向平均气膜冷却效率提升10–25%(尤其在M=1.5时更为显著);而逆压梯度会导致小幅下降,其中M=0.5时出口附近区域降幅最高达10%,M=1.5时远场区域降幅为10–15%。M=1.5的大涡模拟结果显示:顺压梯度下的气膜冷却增强与反肾形涡对(Anti-CVP)及孔间涡的形成密切相关,这些涡结构促进了气膜的横向输运并改善了展向覆盖;反之,逆压梯度会引发射流抬升,加剧主次流掺混,导致冷却效率下降。湍流动能(TKE)分析进一步验证了上述结论。本研究的创新性在于:首次定量评估了流向压力梯度对锯齿槽-孔气膜冷却的影响(该问题在既往研究中鲜有涉及),并通过实验与模拟相结合的方法系统揭示了性能变化规律与流动机制。

HUANG Kenan, ZHANG Jingzhou, LI Guoneng, ZHU Yiyuan, SHEN Rong, BU Zhongming

. Mainstream Pressure Gradient on Film Cooling Characteristics of a Serrated Trenched-Hole[J]. 热科学学报, 2026

, 35(1)

: 97

-114

.

DOI: 10.1007/s11630-025-2208-0

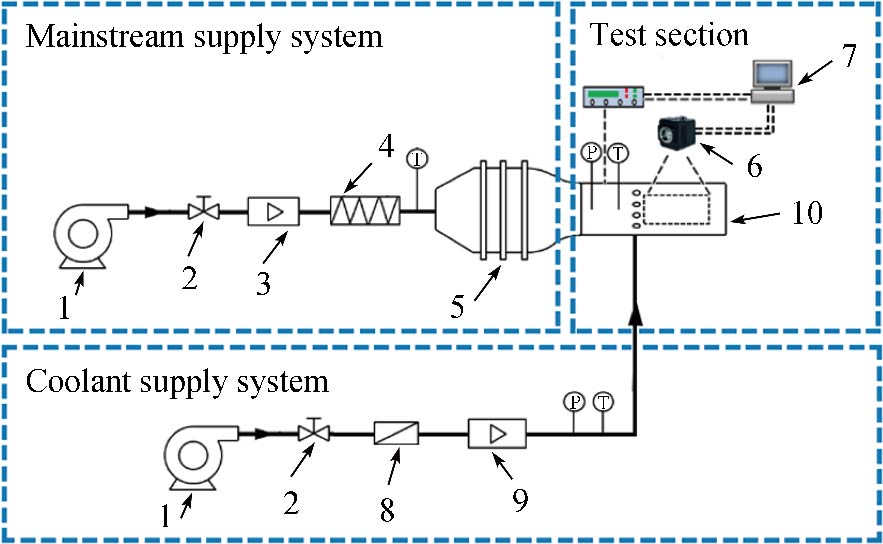

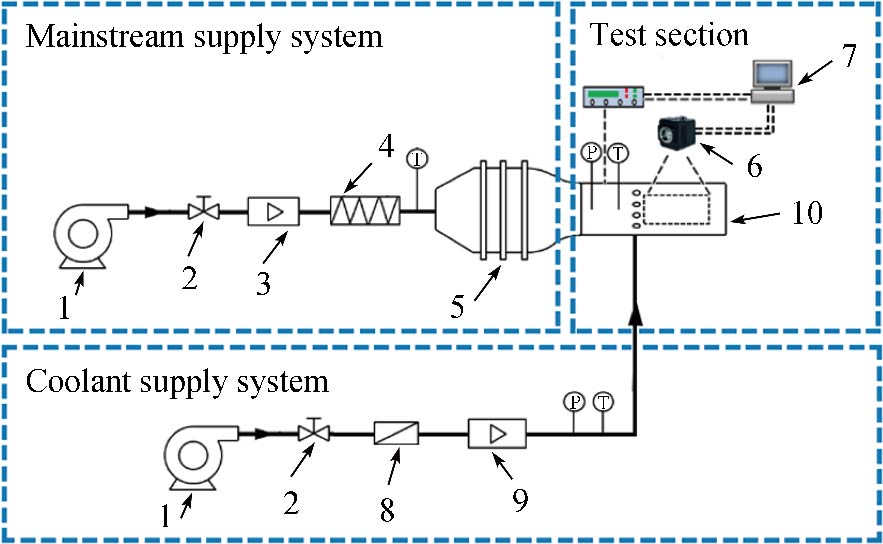

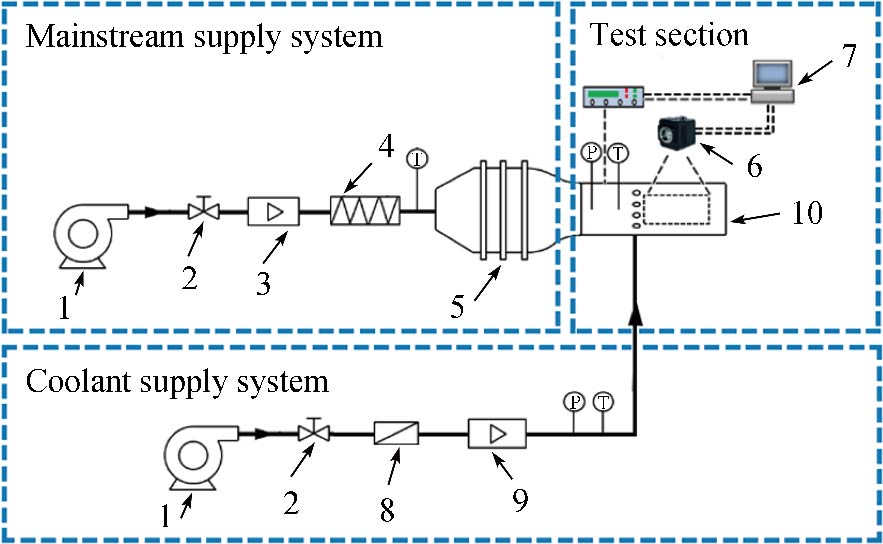

Film cooling remains a critical technique for protecting turbine blades under high thermal loads, yet developing high-performance film cooling structures while maintaining structural integrity and manufacturability remains a major challenge. Serrated trenched-hole designs offer enhanced coolant coverage and manufacturability advantages over conventional shaped holes, but their performance under various streamwise pressure gradient conditions has not been systematically explored. This study investigates the impacts of mainstream streamwise pressure gradients, including zero, adverse, and favorable, on characteristics of serrated trenched-hole film cooling, with comparisons to conventional cylindrical holes. A combination of experimental measurements and Large Eddy Simulation (LES) is employed to investigate flow dynamics and film cooling performance under various pressure gradients and at blowing ratios of M=0.5 and M=1.5. Experimental results demonstrate that the serrated trench consistently enhances film cooling effectiveness. Under adverse pressure gradients, it mitigates the reduction in film cooling performance and improves both streamwise and spanwise coverage. Particularly at M=1.5, the serrated trench improves near-exit region film cooling effectiveness by roughly 2–3 times compared to cylindrical holes. Under favorable pressure gradient, the serrated trench further optimizes cooling effectiveness by promoting both spanwise continuity and streamwise expansion of the coolant film, with the maximum film cooling effectiveness in the near-exit region reaching approximately 0.9. Favorable streamwise pressure gradients enhance the laterally averaged film cooling effectiveness of the serrated trench by 10%–18% compared to the zero-pressure gradient case, especially at M=1.5. While adverse pressure gradients lead to a modest reduction of film cooling effectiveness, with decreases of up to 10% in the near-exit region at M=0.5 and 10%–15% in the far-field at M=1.5. LES results at M=1.5 reveal that film cooling enhancement under favorable pressure gradients is closely associated with the formation of Anti-CVP (Anti-Counter-rotating Vortex Pair) and inter-hole vortices, which facilitate lateral coolant transport and improve spanwise coverage. Conversely, adverse pressure gradients induce jet lift-off, intensifying mainstream-coolant mixing, leading to diminished cooling effectiveness. Turbulence kinetic energy (TKE) analysis further supports these findings. The novelty of this work lies in its quantitative assessment of streamwise pressure gradient effects on trenched-hole film cooling, which is scarcely addressed in prior research, and in its integrated use of experimental and LES approaches to elucidate both performance trends and underlying flow mechanisms.