[1] Dostal V., Hejzlar P., Driscoll M.J., High-performance supercritical carbon dioxide cycle for next-generation nuclear reactors. Nuclear Technology, 2006, 154(3): 265–282.

[2] Du Y., Yang C., Wang H., et al., One-dimensional optimisation design and off-design operation strategy of centrifugal compressor for supercritical carbon dioxide Brayton cycle. Applied Thermal Engineering, 2021, 196: 117318.

[3] Dostal V., Hejzlar P., Driscoll M.J., The supercritical carbon dioxide power cycle: comparison to other advanced power cycles. Nuclear Technology, 2006, 154(3): 283–301.

[4] Jeong W.S., Lee J.I., Jeong Y.H., Potential improvements of supercritical recompression CO2 Brayton cycle by mixing other gases for power conversion system of a SFR. Nuclear Engineering and Design, 2011, 241(6): 2128–2137.

[5] Utamura M., Fukuda T., Aritomi M., Aerodynamic characteristics of a centrifugal compressor working in supercritical carbon dioxide. Energy Procedia, 2012, 14: 1149–1155.

[6] Monje B., Sánchez D., Savill M., et al., A Design Strategy for Supercritical CO2 Compressors. American Society of Mechanical Engineers, 2014, Paper No: GT2014-25151.

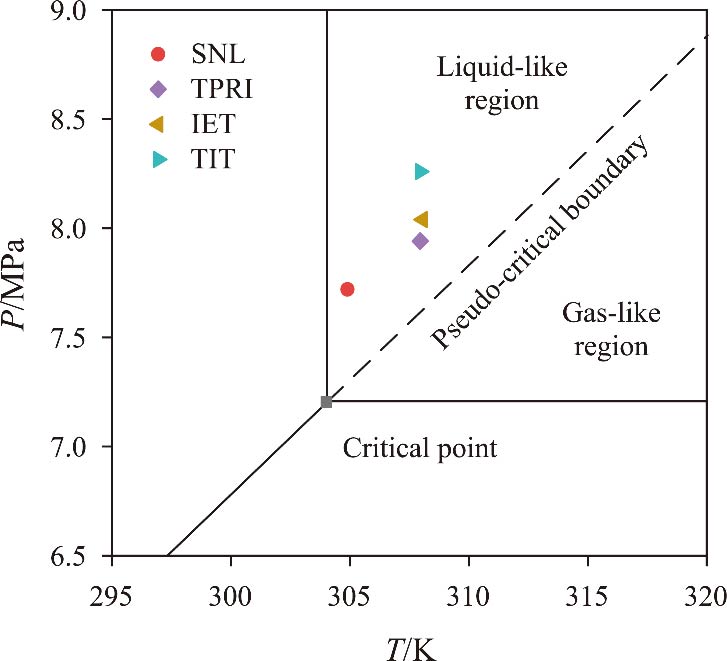

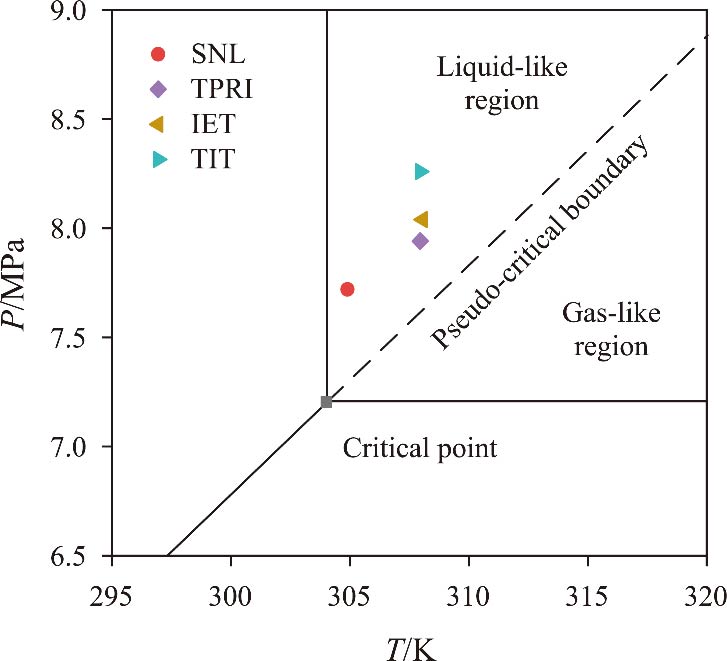

[7] Wright S.A., Radel R.F., Vernon M.E., et al., Operation and analysis of a supercritical CO2 Brayton cycle. Sandia National Laboratories, No. SAND2010-0171.

[8] Utamura M., Hasuike H., Ogawa K., et al., Demonstration of supercritical CO2 closed regenerative Brayton cycle in a bench scale experiment. Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, 2012, 3: 155–164.

DOI: https://doi.org/10.1115/GT2012-68697.

[9] Conboy T., Pasch J., Fleming D., Control of a supercritical CO2 recompression Brayton cycle demonstration loop. Journal of Engineering for Gas Turbines and Power, 2013, 135(11): 111701.

[10] Qin S., Liang S., Zhu Y., et al., Experiment and simulation of the speed-up process of supercritical carbon dioxide closed Brayton cycle compressor. Applied Sciences, 2023, 13(6): 3566.

[11] Li H., Zhang Y., Yao M., et al., Design assessment of a 5 MW fossil-fired supercritical CO2 power cycle pilot loop. Energy, 2019, 174: 792–804.

[12] Kimball K.J., Clementoni E.M., Supercritical carbon dioxide Brayton power cycle development overview. American Society of Mechanical Engineers, 2012, Paper No: GT2012-68204.

[13] Sun E., Sun Y., Feng S., et al., Thermodynamic study of organic Rankine cycle based on extraction steam compression regeneration in the supercritical state. Energy Conversion and Management, 2023, 293: 117546.

[14] Sun E., Wang X., Qian Q., et al., Proposal and application of supercritical steam Rankine cycle using supercritical reheating regeneration process and its comparison between S-CO2 Brayton cycle. Energy Conversion and Management, 2023, 280: 116798.

[15] Rinaldi E., Pecnik R., Colonna P., Computational fluid dynamic simulation of a supercritical CO2 compressor performance map. Journal of Engineering for Gas Turbines and Power, 2015, 137(7): 072602

[16] Zhang L., Yang Z., Sun E., et al., Numerical simulation study on influence of equation of state on internal flow field and performance of S-CO2 compressor. Journal of Thermal Science, 2024, 33(3): 888–898.

[17] Zhang L., Yang Z., Dong Z., et al., Effects of different CO2 equations of state on Condensation Position in Numerical Investigation. GPPS Xi’an21, 2022.

[18] Liu Y., Zhao Y., Yang Q., et al., Research on compression process and compressors in supercritical carbon dioxide power cycle systems: A review. Energy, 2024, 297: 131288.

[19] Cho S.K., Son S., Lee J., et al., Optimum loss models for performance prediction of supercritical CO2 centrifugal compressor. Applied Thermal Engineering, 2021, 184: 116255.

[20] Zhang C., Dong X., Liu X., et al., A method to select loss correlations for centrifugal compressor performance prediction. Aerospace Science and Technology, 2019, 93: 105335.

[21] Velasquez E.I., Determination of a suitable set of loss models for centrifugal compressor performance prediction. Chinese Journal of Aeronautics, 2017, 30(5): 1644–1650.

[22] Li Y., Ma Q., Zhang E., Bai B., High-performance aerodynamic design of supercritical CO2 centrifugal compressor for the Megawatt-class nuclear microreactor (MSC-GFR). Nuclear Engineering and Design, 2023, 413: 112582.

[23] Oh H.W., Yoon E.S., Chung M.K., An optimum set of loss models for performance prediction of centrifugal compressors. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 1997, 211: 331–338.

[24] Conrad O., Raif K., Wessels M., The calculation of performance maps for centrifugal compressors with vane-island diffusers. Performance Prediction of Centrifugal Pumps and Compressors, 1979: 135–147.

[25] Coppage J.E., Dallenbach F., Eichenberger H.P., et al., Study of supersonic radial compressors for refrigeration and pressurization systems. Wright Air Development Center, 1956: 157–163.

[26] Galvas M.R., Analytical correlation of centrifugal compressor design geometry for maximum efficiency with specific speed. National Aeronautics and Space Administration, 1972.

[27] Jansen W., A method for calculating the flow in a centrifugal impeller when entropy gradient are present. Institution of Mechanical Engineers, 1970, pp: 133–146.

[28] Li Y., Lu G., Centripetal turbine and centrifugal compressor. China Machine Press, Beijing, 1987, pp: 94–108.

[29] Wu B.H., Xi G., Wang S., et al., Research on performance predictive model for centrifugal compressor. Chinese Journal of Turbomachinery, 1999, 41(3): 5–8.

[30] Daily J.W., Nece R.E., Chamber dimension effects on induced flow and frictional resistance of enclosed rotating disks. Journal of Basic Engineering, 1960, 82: 217–230.

[31] Aungier R.H., Mean streamline aerodynamic performance analysis of centrifugal compressors. Journal of Turbomachinery, 1995, 117(3): 360–366.

[32] Teng G., Shen X., Ouyang H., et al., Research on performance prediction model of supercritical carbon dioxide centrifugal compressor. Thermal Power Generation, 2020, 49(10): 173–179.

[33] Yan X., Zuo Z.T., Liang Q., et al., Research of off-design performance prediction model of centrifugal compressor with adjustable guide vane. Proceedings of the CSEE, 2016, 36(12): 3381–3390.