[1] Ameli A., Afzalifar A., Turunen-Saaresti T., et al., Centrifugal compressor design for near-critical point applications. Journal of Engineering for Gas Turbines and Power, 2019, 141(3): 031016.

[2] Cheng K., Qin J., Sun H., et al., Power optimization and comparison between simple recuperated and recompressing supercritical carbon dioxide Closed-Brayton-Cycle with finite cold source on hypersonic vehicles. Energy, 2019, 181: 1189–1201.

[3] Ming Y., Liu K., Zhao F., et al., Dynamic modeling and validation of the 5 MW small modular supercritical CO2 Brayton-Cycle reactor system. Energy Conversion and Management, 2022, 253: 115184.

[4] Son S., Heo J.Y., Kim N.I., et al., Reduction of CO2 emission for solar power backup by direct integration of oxy-combustion supercritical CO2 power cycle with concentrated solar power. Energy Conversion and Management, 2019, 201: 112161.

[5] Carraro G., Danieli P., Lazzaretto A., et al., A common thread in the evolution of the configurations of supercritical CO2 power systems for waste heat recovery. Energy Conversion and Management, 2021, 237: 114031.

[6] Zhang L., Zhou J., Zuo S., et al., Anti-freezing mechanism of the direct air-cooled system by splitting columns operation. International Communications in Heat and Mass Transfer, 2024, 158: 107883.

[7] Zhang L., Zhou J., Zuo S., et al., Effect mechanism of ambient air parameters on the thermal performance for cooling towers. Journal of Thermal Science and Engineering Applications, 2024, 16(1): 011011.

[8] Li Y., Ding J., Sun H., et al., Performance analysis of the inverted Brayton cycle in the atmospheric solid oxide fuel cell hybrid power system. Energy Conversion and Management, 2024, 316: 118828.

[9] Shaaban S., Design optimization of a centrifugal compressor vaneless diffuser. International Journal of Refrigeration, 2015, 60: 142–154.

[10] Wright S.A., Radel R.F., Vernon M.E., et al., Operation and analysis of a supercritical CO2 Brayton cycle. Sandia National Laboratories (SNL), Albuquerque, NM, USA, 2010, 87185-MS1136.

[11] Zhang L., Yang Z., Sun E., et al., Numerical simulation study on influence of equation of state on internal flow field and performance of s-CO2 compressor. Journal of Thermal Science, 2024, 33(3): 888–898.

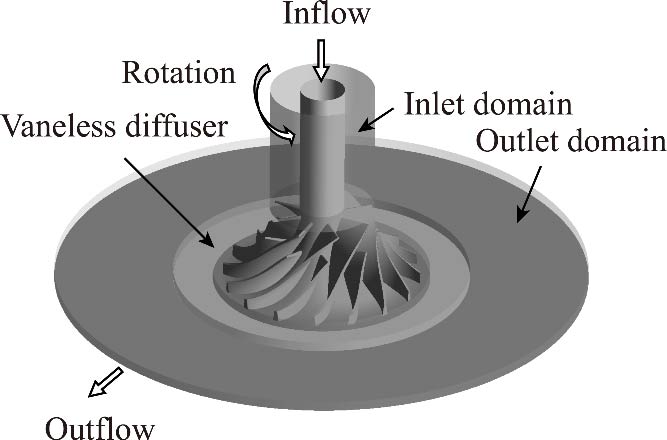

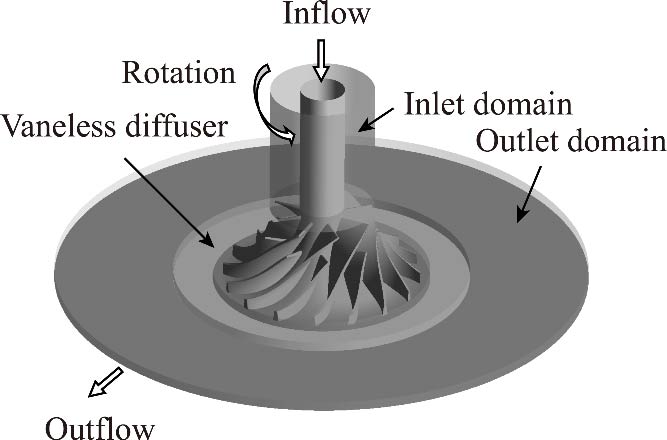

[12] Zhang L., Yang F., An G., et al., Investigation of a rotating stall in a supercritical CO2 centrifugal compressor. Physics of Fluids, 2024, 36(5): 054102.

[13] Zhang L., An G., Lang J., et al., Investigation of the unsteady flow mechanism in a centrifugal compressor adopted in the compressed carbon dioxide energy storage system. Journal of Energy Storage, 2024, 104: 114488.

[14] Lopez A., Monje B., Sanchez D., et al., Effect of turbulence and flow distortion on the performance of conical diffusers operating on supercritical carbon dioxide. Turbo Expo: Power for Land, Sea, and Air, American Society of Mechanical Engineers, SAN Antonio, USA, 2013, 55294: V008T34A002.

DOI: https://doi.org/10.1115/GT2013-94009.

[15] Liu Z., Wang P., Zhao B., Numerical investigation of the rotating instability uniqueness in a MW scale supercritical carbon dioxide centrifugal compressor. Korean Journal of Chemical Engineering, 2022, 39(11): 2935–2944.

[16] Cao R., Li Z., Deng Q., et al., Design and aerodynamic performance investigations of centrifugal compressor for 150 kW class supercritical carbon dioxide simple brayton cycle. Turbo Expo: Power for Land, Sea, and Air, American Society of Mechanical Engineers, London, UK, 2020, 84232: V011T031A019.

DOI: https://doi.org/10.1115/GT2020-16156.

[17] Zhang H., Yang Y., Xu C., et al., Numerical study of the coherent characteristics of the blade tip of a micro centrifugal compressor and its application in a new unsteady casing-treatment experiment. Physics of Fluids, 2024, 36(1): 017139.

[18] Yang Z., Jiang H., Zhuge W., et al., Flow loss mechanism in a supercritical carbon dioxide centrifugal compressor at low flow rate conditions. Journal of Thermal Science, 2024, 33(1): 114–125.

[19] Cai R., Yang M., Yang B., et al., Study of unsteady shear flow near stall in a shrouded supercritical carbon dioxide centrifugal compressor. Physics of Fluids, 2024, 36(11): 114104.

[20] Gooding W.J., Fabian J.C., Key N.L., Laser doppler velocimetry characterization of unsteady vaned diffuser flow in a centrifugal compressor. Journal of Turbomachinery, 2020, 142(4): 041001.

[21] Stuart C., Spence S., Filsinger D., et al., A three-zone modeling approach for centrifugal compressor slip factor prediction. Journal of Turbomachinery, 2019, 141(3): 031008.

[22] Zheng Q., Liu S., Numerical investigation on the formation of jet-wake flow pattern in centrifugal compressor impeller. Turbo Expo: Power for Land, Sea, and Air, 2003, 36894: 755–764.

[23] Gooding W.J., Fabian J.C., Key N.L., LDV characterization of unsteady vaned diffuser flow in a centrifugal compressor. Journal of Turbomachinery, 2020, 142(4): 1–10.

[24] Hong S.S., Schleer M., Abhari R.S., Effect of tip clearance on the flow and performance of a centrifugal compressor. Fluids Engineering Division Summer Meeting, Hawaii, USA, 2003, 36975: 563–569.

[25] Chen Z., Yang S., Li X., et al., Investigation on leakage vortex cavitation and corresponding enstrophy characteristics in a liquid nitrogen inducer. Cryogenics, 2023, 129: 103606.

[26] Zeng L., Gao Z., Xu T., et al., Mechanism analysis of the vortex ring and its effects on an axial descending rotor. International Journal of Fluid Engineering, 2024, 1(2): 023101.

[27] Zhang L., He R., Wang X., et al., Study on static and dynamic characteristics of an axial fan with abnormal blade under rotating stall conditions. Energy, 2019, 170: 305–325.

[28] An G., Kang J., Zou Y., et al., Investigation of the unsteady flow in a transonic axial compressor adopted in the compressed air energy storage system. Journal of Energy Storage, 2023, 63: 106928.

[29] An G., Kang J., Wang L., et al., Decoupling and reconstruction analysis in a transonic axial compressor using the dynamic mode decomposition method. Physics of Fluids, 2023, 35(8): 084120.

[30] Schleer M., Song S.J., Abhari R.S., Clearance effects on the onset of instability in a centrifugal compressor. Journal of Turbomachinery, 2008, 130(3): 031002.

[31] Bulot N., Trébinjac I., Effect of the unsteadiness on the diffuser flow in a transonic centrifugal compressor stage. International Journal of Rotating Machinery, 2009, 2009(1): 932593.

[32] Zhang L., Zheng Z., Zhang Q., et al., Study of rotating stall in a centrifugal compressor with wide vaneless diffuser. Journal of Thermal Science, 2020, 29(3): 743–752.

[33] Zhang L., Kang J., Lang J., et al., Stall evolution mechanism of a centrifugal compressor with a wide-long vaneless diffuser. Journal of Thermal Science, 2024, 33(3): 899–913.

[34] Liu Z., Luo W., Zhao Q., et al., Preliminary design and model assessment of a supercritical CO2 compressor. Applied Sciences, 2018, 8(4): 595.

[35] Li X., Cao Z., Wei Z., et al., Theoretical model of energy conversion and loss prediction for multi-stage centrifugal pump as turbine. Energy Conversion and Management, 2025, 325: 119379.

[36] Schleer M., Abhari R.S., Clearance effects on the evolution of the flow in the vaneless diffuser of a centrifugal compressor at part load condition. Journal of Turbomachinery, 2008, 130(3): 031009.

[37] Hah C., Krain H., Secondary flows and vortex motion in a high-efficiency backswept impeller at design and off-design conditions. Journal of Turbomachinery, 1990, 112(1): 7–13.