LIU Yunfeng

,

YAN Han

,

DU Wei

,

ZHANG Hongtao

,

LI Yufeng

,

WEN Fengbo

,

ZHOU Xun

. Aerodynamic Performance Analysis on Blade Snubber with Bionic Structure[J]. 热科学学报, 2025

, 34(2)

: 579

-589

.

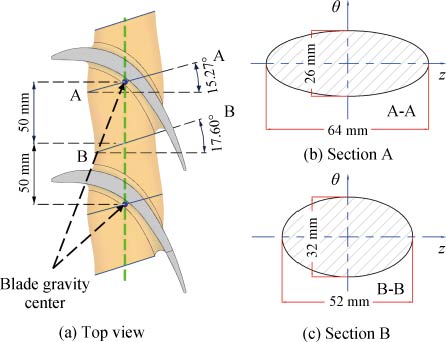

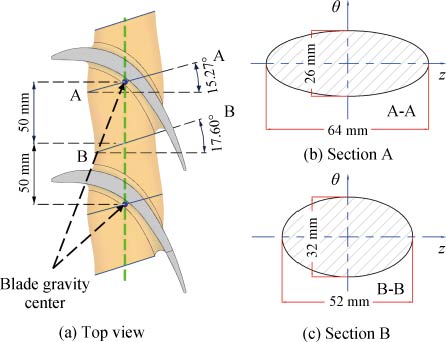

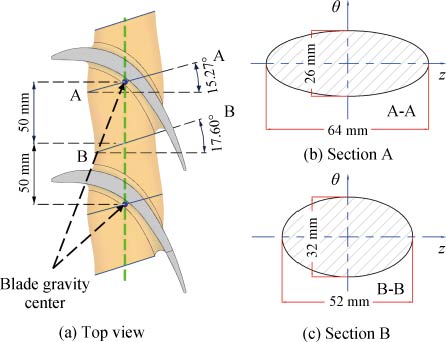

DOI: 10.1007/s11630-025-2093-6

The utilization of a part-span connector (PSC) has the potential to enhance the blade frequency, but with the penalty of aerodynamic performance. In this study, we numerically investigate the aerodynamic performance of two types of bionic structure snubbers: (1) Harbor seal whisker (HSW) and (2) Atropus’s body shape (ABS). The investigation is conducted by solving the three-dimensional Reynolds-Averaged Navier-Stokes (RANS) equations and utilizing the SST turbulent model. In this study, the performance impact of classical snubbers on a cascade blade has been examined by modeling it with and without an ellipse-shaped snubber. The vortex induced by the snubber predominantly manifests on the suction side and can be categorized into three primary vortices: upper, lower, and tail. The upper and lower vortices serve as the primary contributors to loss. Compared to the conventional ellipse snubber, the ABS snubber exhibits a reduction in the total pressure loss coefficient by 0.11% and an increase in the mass flow rate by 0.41%. On the contrary, the implementation of the HSW snubber has the potential to mitigate parameter fluctuations. However, it is important to note that this comes at the cost of a 0.10% increase in the total pressure loss coefficient and a 0.20% decrease in mass flow rate. This article further examines the factors contributing to these disparities.

[1] Ahmad M., Experimental assessment of droplet impact erosion of low pressure steam turbine blades. Aachen: Shaker, 2009.

[2] Przysowa R., Blade vibration monitoring in a low-pressure steam turbine. Turbo Expo: Power for Land, Sea, and Air. ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 2018, Paper No: GT2018-76657.

[3] Mukhopadhyay N.K., Chowdhury S.G., Das G., et al., An investigation of the failure of low pressure steam turbine blades. Engineering Failure Analysis, 1998, 5(3): 181–193.

[4] Sreekumar P., Varpe M.K., Effect of snubbers and lacing wire on aerodynamic performance of last stage steam turbine. ASME 2019 Gas Turbine India Conference, Tamil Nadu, India, 2019, Paper No: GTINDIA2019-2509.

[5] Traupel W., Thermische Turbomaschinen: Band 1: Thermodynamisch-strömungstechnische Berechnung. Springer-Verlag, 2019.

[6] Denton J.D., Loss mechanisms in turbomachines. ASME 1993 International Gas Turbine and Aeroengine Congress and Exposition, Ohio, USA, 1993, Paper No: 93-GT-435.

[7] Craig H.R.M., Cox H.J.A., Performance estimation of axial flow turbines. Proceedings of the Institution of Mechanical Engineers, 1970, 185(1): 407–424.

[8] Rubechini F., Marconcini M., Arnone A., et al., Some aspects of CFD modeling in the analysis of a low-pressure steam turbine. ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, Canada, 2007, Paper No: GT2007-27235.

[9] Chima R.V., Computational modeling of vortex generators for turbomachinery. ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, the Netherlands, 2002.

DOI: 10.1115/GT2002-30677

[10] Brüggemann C., Schatz M., Vogt D.M., et al., A numerical investigation of the impact of part-span connectors on the flow field in a linear cascade. ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, North Carolina, USA, 2017, Paper No: GT2017-63359.

[11] Mistry H., Santhanakrishnan M., Liu J., et al., Aerodynamic performance assessment of part-span connector of last stage bucket of low pressure steam turbine. ASME 2011 Power Conference collocated with JSME ICOPE, Colorado, USA, 2011, Paper No: POWER2011-55265.

[12] Li B., Li J., Numerical investigations on the aerodynamic performance of last stage bucket with part-span connector. ASME 2014 International Mechanical Engineering Congress and Exposition, Quebec, Canada, 2014, Paper No: IMECE2014-38039.

[13] Häfele M., Starzmann J., Grübel M., et al., Numerical investigation of the impact of part-span connectors on aero-thermodynamics in a low pressure industrial steam turbine. ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 2014, Paper No: GT2014-25177.

[14] Wu Y.T., Funk C.K., Hsu P., et al., Design optimization of turbo-machinery components with independent FEA and CFD tools in an optimization software environment: A mid-span shroud ring study case. ASME 2011 International Mechanical Engineering Congress and Exposition, Colorado, USA, 2011, Paper No: IMECE2011-62083.

[15] Hanke W., Witte M., Miersch L., et al., Harbor seal vibrissa morphology suppresses vortex-induced vibrations. Journal of Experimental Biology, 2010, 213(15): 2665–2672.

[16] Chen W.L., Min X.W., Gao D.L., et al., Experimental investigation of aerodynamic forces and flow structures of bionic cylinders based on harbor seal vibrissa. Experimental Thermal and Fluid Science, 2018, 99: 169–180.

[17] Lin Y.F., Bai H.L., Alam Md.M., et al., Effects of large spanwise wavelength on the wake of a sinusoidal wavy cylinder. Journal of Fluids and Structures, 2016, 61: 392–409.

[18] Huang X.Q., He L., Bell D.L., Experimental and computational study of oscillating turbine cascade and influence of part-span shrouds. Journal of Fluids Engineering, 2009, 131(5): 051102.

[19] Arts T., de Rouvroit L.M., Aero-thermal performance of a two-dimensional highly loaded transonic turbine nozzle guide vane: A test case for inviscid and viscous flow computations. Journal of Turbomachinery, 1990, 114(1): 147–154.