[1] Vakilzadeh A.H., Sarvestani A.B., Javaherdeh K., et al., Heat transfer and fluid flow in a PCM-filled enclosure: Effect of heated wall configuration. Journal of Energy Storage, 2024, 87: 111448.

https://doi.org/10.1016/j.est.2024.111448

[2] Tan F.L., Constrained and unconstrained melting inside a sphere. International Communications in Heat and Mass Transfer, 2008, 35(4): 466–475.

https://doi.org/10.1016/j.icheatmasstransfer.2007.09.008

[3] Tan F.L., Hosseinizadeh S.F., Khodadadi J.M., et al., Experimental and computational study of constrained melting of phase change materials (PCM) inside a spherical capsule. International Journal of Heat and Mass Transfer, 2009, 52(15–16): 3464–3472.

https://doi.org/10.1016/j.ijheatmasstransfer.2009.02.043

[4] Liu Y., Numerical study on phase change heat storage capsule and its accumulation heat storage characteristics. Northeast Electric Power University, 2018.

[5] Zhang Z., Liu Y., Jiang T., et al., Analysis of heat storage process of phase change capsules with holes. Chemical Progress, 2017, 36(6): 2123–2130.

10.16085/j.issn.1000-6613.2017.06.022

[6] Chen Z., Analysis of heat transfer performance of high temperature phase change capsule heat storage. Zhengzhou University, 2020.

10.27466/d.cnki.gzzdu.2020.000970

[7] Dukhan W.A., Dhaidan N.S., Al-Hattab T.A., et al., Phase-change of paraffin inside heat exchangers: an experimental study. International Journal of Environmental Science and Technology, 2022, 19(4): 3155–3164. https://doi.org/10.1007/s13762-021-03367-2

[8] Milyani A.H., Attar E.T., Abdulaal M.J., et al., Thermal analysis of battery cells placed in triangular enclosures filled with PCM in the presence of forced airflow in an air duct. Journal of Building Engineering, 2022, 57: 104887. https://doi.org/10.1016/j.jobe.2022.104887

[9] Sun Y.S., Xu J.Y., Wang H.J., et al., Effects of natural and Marangoni convections on melting of high-temperature encapsulated phase change material under the earth and the moon gravities. Applied Thermal Engineering, 2022, 201: 117760.

https://doi.org/10.1016/j.applthermaleng.2021.117760

[10] Elmozughi A.F., Solomon L., Oztekin A., et al., Encapsulated phase change material for high temperature thermal energy storage—Heat transfer analysis. International Journal of Heat and Mass Transfer, 2014, 78: 1135–1144. https://doi.org/10.1016/j.ijheatmasstransfer.2014.07.087

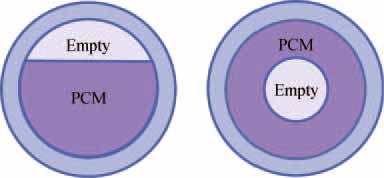

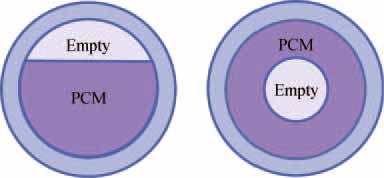

[11] Solomon L., Elmozughi A.F., Oztekin A., et al., Effect of internal void placement on the heat transfer performance—Encapsulated phase change material for energy storage. Renewable Energy, 2015, 78: 438–447. https://doi.org/10.1016/j.renene.2015.01.035

[12] Chan C.W., Tan F.L., Solidification inside a sphere—an experimental study. International Communications in Heat and Mass Transfer, 2006, 33(3): 335–341.

https://doi.org/10.1016/j.icheatmasstransfer.2005.10.010

[13] Ismail M., Alkhazaleh A.H., Masri J., et al., Experimental and numerical analysis of paraffin waxes during solidification inside spherical capsules. Thermal Science and Engineering Progress, 2021, 26: 101095.

https://doi.org/10.1016/j.tsep.2021.101095

[14] Archibold A.R., Rahman M., Gonzalez-Aguilar J., et al., Phase change and heat transfer numerical analysis during solidification on an encapsulated phase change material. Energy Procedia, 2014, 57: 653–661.

https://doi.org/10.1016/j.egypro.2014.10.220

[15] Dhaidan N., Hashim H., Abbas A., et al., Discharging of PCM in various shapes of thermal energy storage systems: A review. Journal of Thermal Science, 2023, 32(3): 1124–1154. https://doi.org/10.1007/s11630-023-1793-z

[16] Raul A., Jain M., Gaikwad S., et al., Modelling and experimental study of latent heat thermal energy storage with encapsulated PCMs for solar thermal applications. Applied Thermal Engineering, 2018, 143: 415–428.

https://doi.org/10.1016/j.applthermaleng.2018.07.123

[17] Liu H., Numerical simulation and experimental study on phase change heat storage in packed bed. Shanghai Jiaotong University, 2020.

10.27307/d.cnki.gsjtu.2020.001328

[18] Sun Y., Xu J., Hong F., Numerical study on heat storage system of high temperature cascade phase change capsule packed bed. Refrigeration Technology, 2022, 42(6): 102258.

[19] Li M.J., Jin B., Ma Z., et al., Experimental and numerical study on the performance of a new high-temperature packed-bed thermal energy storage system with macroencapsulation of molten salt phase change material. Applied Energy, 2018, 221: 1–15.

https://doi.org/10.1016/j.apenergy.2018.03.156

[20] Zheng Y., Zhao W., Sabol J.C., et al., Encapsulated phase change materials for energy storage-characterization by calorimetry. Solar Energy, 2013, 87: 117–126.

https://doi.org/10.1016/j.solener.2012.10.003

[21] Sun G., Liu Y., Dong S., et al., Study on novel molten salt-ceramics composite as energy storage material. Journal of Energy Storage, 2020, 28: 101237.

https://doi.org/10.1016/j.est.2020.101237

[22] Sheng N., Guo H., Zhu C., et al., Fabrication and characterization of Sn@Viod@Ceramic phase change macrocapsules for medium-temperature thermal storage. Journal of Energy Storage, 2022, 56: 106069.

https://doi.org/10.1016/j.est.2022.106069

[23] Wickramaratne C., Dhau J.S., Kamal R., et al., Macro-encapsulation and characterization of chloride based inorganic Phase change materials for high temperature thermal energy storage systems. Applied Energy, 2018, 221: 587–596.

https://doi.org/10.1016/j.apenergy.2018.03.146

[24] Zhou X., Bao F., Yamashita S., et al., Storage and heat dissipation behavior of a heat storage ball with an Al-xSi alloy core and alumina ceramic shell. Journal of Energy Storage, 2022, 52: 104955.

https://doi.org/10.1016/j.est.2022.104955

[25] Mathur A., Kasetty R., Oxley J., et al., Using encapsulated phase change salts for concentrated solar power plant. Energy Procedia, 2014, 49: 908–915.

https://doi.org/10.1016/j.egypro.2014.03.098

[26] Li W., Li S.G., Guan S., et al., Numerical study on melt fraction during melting of phase change material inside a sphere. International Journal of Hydrogen Energy, 2017, 42(29): 18232–18239.

https://doi.org/10.1016/j.ijhydene.2017.04.136

[27] Yu D.H., He Z., Shape-remodeled macrocapsule of phase change materials for thermal energy storage and thermal management. Applied Energy, 2019, 247: 503–516.

https://doi.org/10.1016/j.apenergy.2019.04.072

[28] Alam T.E., Dhau J.S., Goswami D.Y., et al., Macroencapsulation and characterization of phase change materials for latent heat thermal energy storage systems. Applied Energy, 2015, 154: 92–101.

https://doi.org/10.1016/j.apenergy.2015.04.086

[29] Gupta R., Shinde S., Yella A., et al., Thermomechanical characterisations of PTFE, PEEK, PEKK as encapsulation materials for medium temperature solar applications. Energy, 2020, 194: 116921.

https://doi.org/10.1016/j.energy.2020.116921

[30] Li Z., Li B., Chen H., et al., Research progress of phase change heat storage technology. Chemical Progress, 2020, 39(12): 5066–5085.

10.16085/j.issn.1000-6613.2020-0376

[31] Gu L., Polytetrafluoroethylene and its application research progress. Zhejiang Chemical Industry, 2020, 51(3): 1–5.

[32] Augspurger M., Becker J., Buchholz J., et al., Three-dimensional numerical and experimental investigation of the behavior of solar salts within thermal storage devices during phase change. Applied Thermal Engineering, 2018, 143: 791–811.

https://doi.org/10.1016/j.applthermaleng.2018.07.134

[33] Solomon L., Elmozughi A.F., Oztekin A., et al., Effect of internal void placement on the heat transfer performance—Encapsulated phase change material for energy storage. Renewable Energy, 2015, 78: 438–447.

https://doi.org/10.1016/j.renene.2015.01.035

[34] Yu B., Experimental and simulation study of solar salt solid-liquid phase transition process under the influence of natural convection. North China Electric Power University (Beijing), 2022.

10.27140/d.cnki.ghbbu.2022.000413

[35] Assis E., Katsman L., Ziskind G., et al., Numerical and experimental study of melting in a spherical shell. International Journal of Heat and Mass Transfer, 2007, 50(9–10): 1790–1804.

https://doi.org/10.1016/j.ijheatmasstransfer.2006.10.007

[36] Tao G., Research on design, preparation and application technology of advanced composite materials with high thermal conductivity. Nanjing University of Technology, 2006.

[37] Li M.J., Jin B., Ma Z., et al., Experimental and numerical study on the performance of a new high-temperature packed-bed thermal energy storage system with macroencapsulation of molten salt phase change material. Applied Energy, 2018, 221: 1–15.

https://doi.org/10.1016/j.apenergy.2018.03.156

[38] Sun Y., Study on heat transfer of high temperature phase change capsule and its packed bed heat storage system. Shanghai Jiaotong University, 2021.

10.27307/d.cnki.gsjtu.2021.000079

[39] Str A., Tc B., Visualization study of the shrinkage void distribution in thermal energy storage capsules of different geometry-ScienceDirect. Experimental Thermal and Fluid Science, 2007, 31(3): 181–189.

https://doi.org/10.1016/j.expthermflusci.2006.03.026.