[1] Jiang Y., Zhan L., Tian X., et al., Thermodynamic performance comparison and optimization of sCO2 Brayton cycle, tCO2 Brayton cycle and tCO2 Rankine cycle. Journal of Thermal Science, 2023, 32(2): 611–627.

[2] Wang K., He Y., Zhu H., Integration between supercritical CO2 Brayton cycles and molten salt solar power towers: A review and a comprehensive comparison of different cycle layouts. Applied Energy, 2017, 195: 819–836.

[3] Li Z., Shi M., Shao Y., et al., Supercritical CO2 cycles for nuclear-powered marine propulsion: preliminary conceptual design and off-design performance assessment. Journal of Thermal Science, 2024, 33(1): 328–347.

[4] Song J., Li X., Ren X., et al., Performance improvement of a preheating supercritical CO2 (S-CO2) cycle based system for engine waste heat recovery. Energy Conversion and Management, 2018, 161: 225–233.

[5] Xu J., Liu C., Sun E., et al., Perspective of S-CO2 power cycles. Energy, 2019, 186: 115831.

[6] Hacks A.J., Schuster S., Brillert D., Stabilizing effects of supercritical CO2 fluid properties on compressor operation. International Journal of Turbomachinery, Propulsion and Power, 2019, 4(3): 20.

[7] Bae S.J., Ahn Y., Lee J., et al., Experimental and numerical investigation of supercritical CO2 test loop transient behavior near the critical point operation. Applied Thermal Engineering, 2016, 99: 572–582.

[8] Lee J., Cho S.K., Lee J.I., The effect of real gas approximations on S-CO2 compressor design. Journal of Turbomachinery, 2018, 140(5): 051007.

[9] Lei F., Zhang C., Preliminary optimization of multi-stage axial-flow industrial process compressors using aero-engine compressor design strategy. Applied Sciences, 2021, 11(19): 9248.

[10] Shao W., Du J., Yang J., et al., Investigation on one-dimensional loss models for predicting performance of multistage centrifugal compressors in supercritical CO2 Brayton cycle. Journal of Thermal Science, 2021, 30: 133–148.

[11] Wright S.A., Radel R.F., Vernon M.E., et al., Operation and analysis of a supercritical CO2 Brayton cycle. Sandia Report, 2010, No. SAND2010-0171.

[12] Utamura M., Hasuike H., Ogawa K., et al., Demonstration of supercritical CO2 closed regenerative Brayton cycle in a bench scale experiment. Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, 2012, Paper No: GT2012-68697.

[13] Cho J., Shin H., Cho J., et al., Preliminary power generating operation of the supercritical carbon dioxide power cycle experimental test loop with a turbo-generator. Proceedings of the 6th International Symposium- Supercritical CO2 Power Cycles, Pittsburgh, PA, USA. 2018.

[14] Liu Z., Luo W., Zhao Q., et al., Preliminary design and model assessment of a supercritical CO2 compressor. Applied Sciences, 2018, 8(4): 595.

[15] Yang Z., Jiang H., Zhuge W., et al., Flow loss mechanism in a supercritical carbon dioxide centrifugal compressor at low flow rate conditions. Journal of Thermal Science, 2024, 33(1): 114–125.

[16] Li M., Zhu H., Guo J., et al., The development technology and applications of supercritical CO2 power cycle in nuclear energy, solar energy and other energy industries. Applied Thermal Engineering, 2017, 126: 255–275.

[17] Yang J., Yang Z., Duan Y., A review on integrated design and off-design operation of solar power tower system with S-CO2 Brayton cycle. Energy, 2022, 246: 123348.

[18] Xu J., Sun E., Li M., et al., Key issues and solution strategies for supercritical carbon dioxide coal fired power plant. Energy, 2018, 157: 227–246.

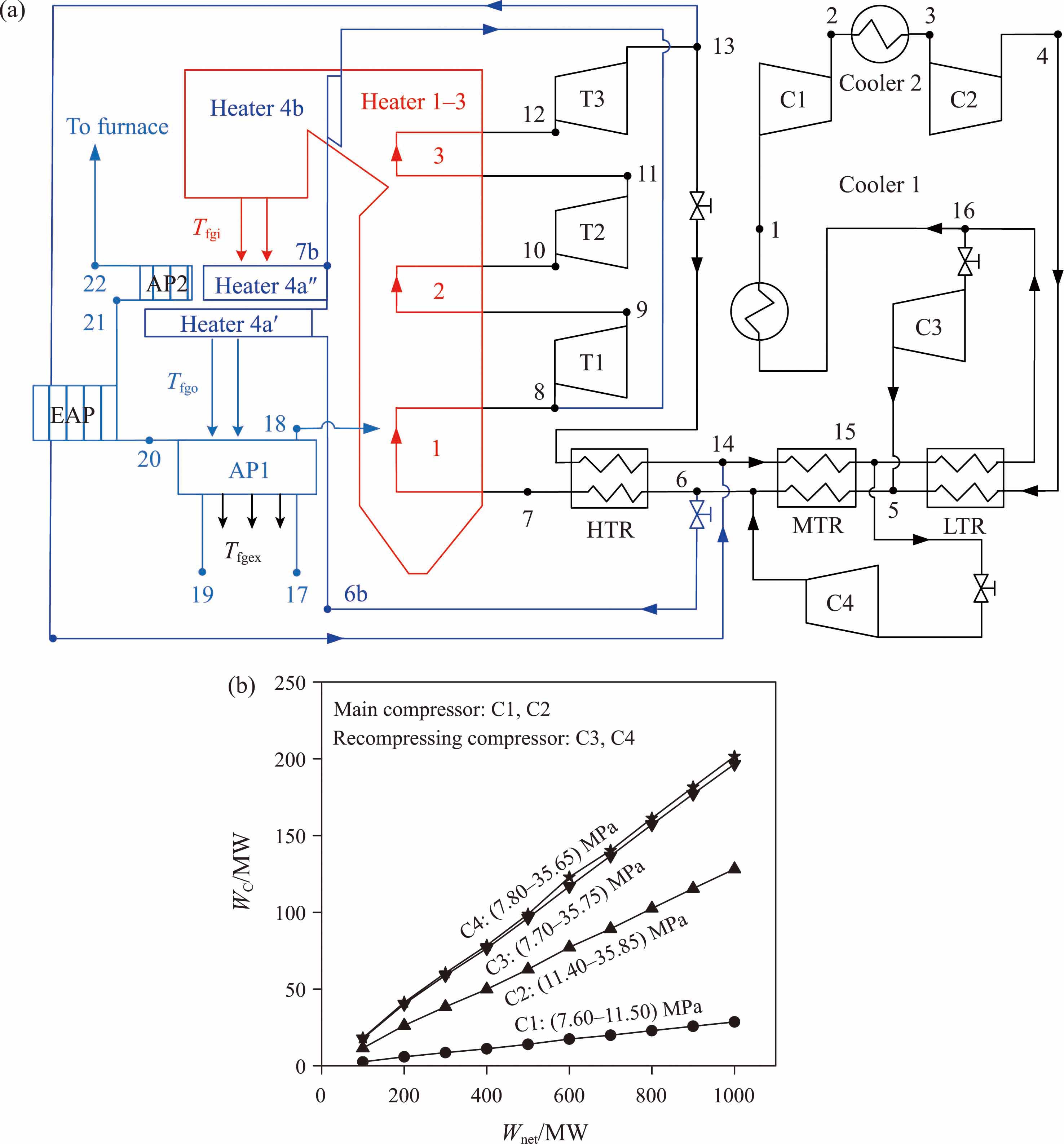

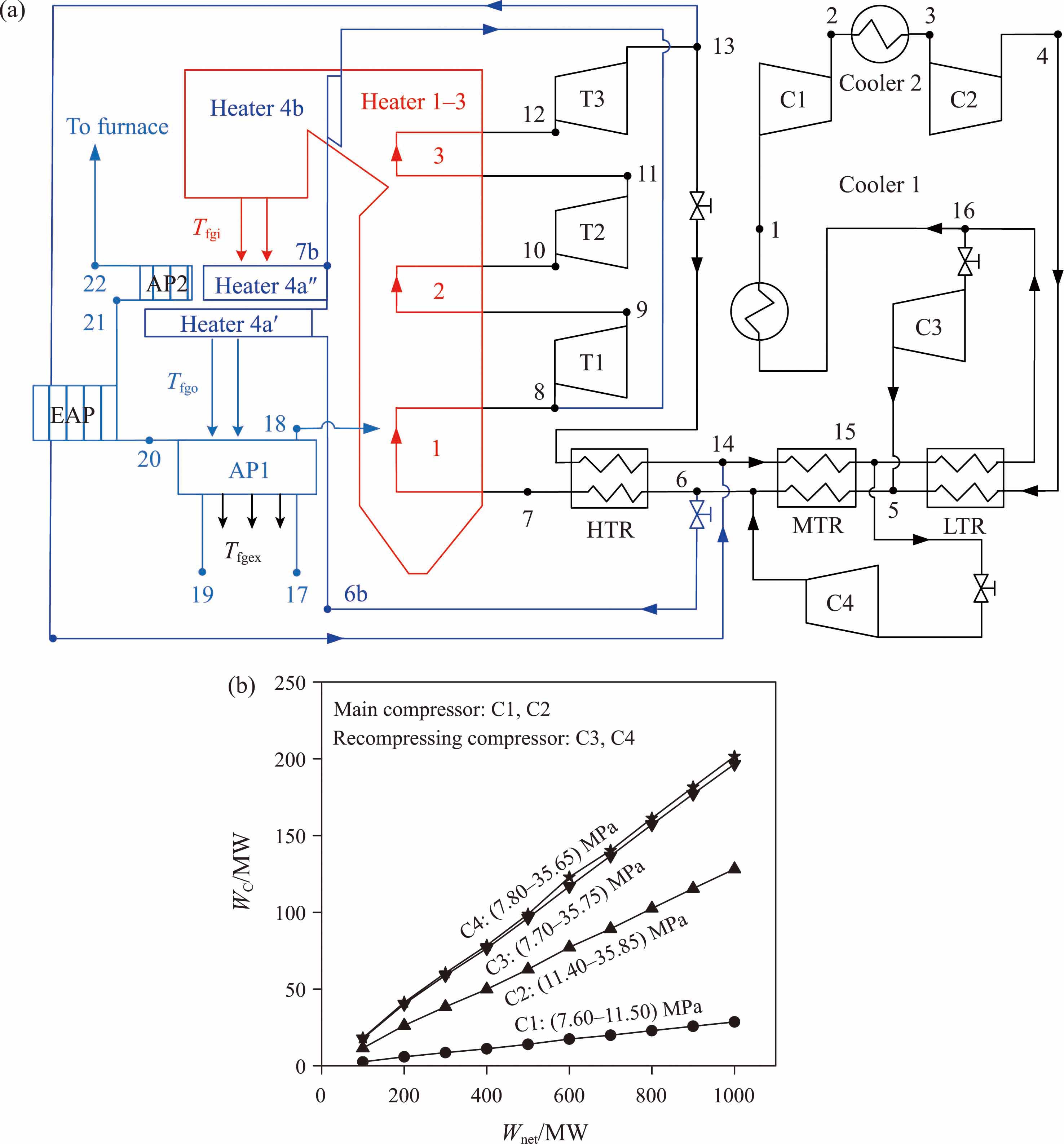

[19] Liu C., Xu J., Li M., et al., Scale law of sCO2 coal fired power plants regarding system performance dependent on power capacities. Energy Conversion and Management, 2020, 226: 113505.

[20] Yang J., Yang Z., Duan Y., Design optimization and operating performance of S-CO2 Brayton cycle under fluctuating ambient temperature and diverse power demand scenarios. Journal of Thermal Science, 2024, 33(1): 190–206.

[21] Wang Y., Gao S., Jiang Q., et al., A new structure of cooling wall tube for supercritical CO2 coal-fired power plants. Journal of Thermal Science, 2023, 32(3): 1239–1250.

[22] Li Z., Li Z., Li J., et al., Leakage and rotor dynamic characteristics for three types of annular gas seals operating in supercritical CO2 turbomachinery. Journal of Engineering for Gas Turbines and Power, 2021, 143(10): 101002.

[23] Yuan T., Li Z., Li J., et al., Design and analysis of cooling structure for dry gas seal chamber of supercritical carbon dioxide turbine shaft end. Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, 2021, Paper No: GT2021-59177.

[24] Wang T., Xu J., Wang Z., et al., Irreversible losses, characteristic sizes and efficiencies of sCO2 axial turbines dependent on power capacities. Energy, 2023, 275: 127437.

[25] Jiang T., Li M., Wang W., et al., Fluid-thermal-mechanical coupled analysis and optimized design of printed circuit heat exchanger with airfoil fins of S-CO2 Brayton cycle. Journal of Thermal Science, 2022, 31(6): 2264–2280.

[26] Li Z., Liu X., Shao Y., et al., Research and development of supercritical carbon dioxide coal-fired power systems. Journal of Thermal Science, 2020, 29: 546–575.

[27] Su R., Yu Z., Wang D., et al., Performance analysis of an integrated supercritical CO2 recompression/absorption refrigeration/kalina cycle driven by medium-temperature waste heat. Journal of Thermal Science, 2022, 31(6): 2051–2067.

[28] Sun E., Xu J., Li M., et al., Synergetics: The cooperative phenomenon in multi-compressions S-CO2 power cycles. Energy Conversion and Management: X, 2020, 7: 100042.

[29] Sun E., Xu J., Hu H., et al., Overlap energy utilization reaches maximum efficiency for S-CO2 coal fired power plant: A new principle. Energy conversion and management, 2019, 195: 99–113.

[30] Li M., Wang G., Xu J., et al., Life cycle assessment analysis and comparison of 1000 MW S-CO2 coal fired power plant and 1000 MW USC water-steam coal-fired power plant. Journal of Thermal Science, 2020, 31: 1–22.

[31] Tournier J.M., El-Genk M.S., Axial flow, multi-stage turbine and compressor models. Energy conversion and management, 2010, 51(1): 16–29.

[32] Qin L., Cao H., Li J., et al., Performance comparison of sorption compressors for methane using metal-organic frameworks and activated carbon as adsorbents. Cryogenics, 2022, 123: 103441.

[33] Peters M., Schmidt T., Jeschke P., Influence of blade aspect ratio on axial compressor efficiency. Journal of the Global Power and Propulsion Society, 2019, 3: 639–652.

[34] Da Lio L., Manente G., Lazzaretto A., New efficiency charts for the optimum design of axial flow turbines for organic Rankine cycles. Energy, 2014, 77: 447–459.

[35] Wang Y., Guenette G., Hejzlar P., et al., Compressor design for the supercritical CO2 Brayton cycle. 2nd International Energy Conversion Engineering Conference. 2004. DOI: 10.2514/6.2004-5722

[36] Smith Jr L.H., Recovery ratio—A measure of the loss recovery potential of compressor stages. Transactions of the American Society of Mechanical Engineers, 1958, 80(3): 517–523.

[37] Aungier R.H., Farokhi S., Axial-flow compressors: a strategy for aerodynamic design and analysis. Applied Mechanics Reviews, 2004, 57(4): B22–B22.

[38] Hosangadi A., Weathers T., Liu J., et al., Numerical predictions of mean performance and dynamic behavior of a 10 MWe SCO2 compressor with test data validation. Journal of Engineering for Gas Turbines and Power, 2022, 144(12): 121019.

[39] Anderson M.R., Improved smith chart for axial compressor design. Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, 2018, Paper No: GT2018-75845.

[40] Monteiro V.G., Iha K., Silva O.F.R., et al., Matching between metamodel and optimization tool applied in a multistage axial-flow compressor aiming design improvements. In: 31st Congress of the International Council of the Aeronautical Sciences. Belo Horizonte, Brazil, 9–14, September, 2018.

[41] Chana K.S., Miller R.J., The effect of reaction on compressor performance. Journal of Turbomachinery, 2023, 145(2): 021012.

[42] Fuller R., Preuss J., Noall J., Turbomachinery for supercritical CO2 power cycles. Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, 2012, Paper No: GT2012-68735.

[43] Allison T., Wilkes J., Brun K., et al., Turbomachinery overview for supercritical CO2 power cycles. Proceedings of the 46th Turbomachinery Symposium. Turbomachinery Laboratory, Texas A&M Engineering Experiment Station, 2017.

[44] Pelton R., Bygrave J., Wygant K., et al., Near critical point testing and performance results of a sCO2 compressor for a 10 MWe Brayton cycle. Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, 2022, Paper No: GT2022-83503.

[45] Moisseytsev A., Sienicki J.J., Development of a plant dynamics computer code for analysis of a supercritical carbon dioxide Brayton cycle energy converter coupled to a natural circulation lead-cooled fast reactor. Argonne National Lab, Argonne, IL, 2007.

[46] Arenas Pinilla E.M., Cantizano González A., Asenjo Pedraza I., et al., Design and analysis of radial and axial turbomachinery of supercritical CO2 power cycles. Engineering, Environmental Science, 2019.

[47] Yan W., Sun Z., Zhou J., et al., Numerical simulation of transonic compressors with different turbulence models. Aerospace, 2023, 10(9): 784.

[48] Wang Y., Zhang H., Wu Y., et al., Supersonic compressor cascade flow control using plasma actuation at low Reynolds number. Physics of Fluids, 2022, 34(2): 027105.

[49] Wang Z., Zheng H., Xu J., et al., The roadmap towards the efficiency limit for supercritical carbon dioxide coal fired power plant. Energy Conversion and Management, 2022, 269: 116166.

[50] Zhang M., Du J., Zhao H., et al., Design optimization of non-axisymmetric vane for an axial compressor under inlet distortion. Journal of Thermal Science, 2023, 32(4): 1321–1334.

[51] Aungier R.H., Turbine aerodynamics: axial-flow and radial-inflow turbine design and analysis. 2006. ASME, Three Park Avenue. New York, NY 10016: American Society of Mechanical Engineers.

[52] Koch C.C., Smith Jr L.H., Loss sources and magnitudes in axial-flow compressors. ASME Journal of Engineering for Gas Turbines and Power, 1976, 98(3): 411–424.

[53] Saravanamuttoo H.I.H., Rogers G.F.C., Cohen H., Gas turbine theory. Pearson education, 2001.

[54] Cich S.D., Moore J., Mortzheim J.P., et al., Design of a supercritical CO2 compressor for use in a 10 MWe power cycle. The 6th International Supercritical CO2 Power Cycles Symposium, Pittsburgh, Pennsylvania, 2018.

[55] Denton J.D., Loss mechanisms in turbomachines. 1993, American Society of Mechanical Engineers.

[56] Dhar E., Srivatsa S., Kumar P., Feasibility of a direct coupled turbine-compressor power block for S-CO2 Brayton cycles. Proceedings of ASME Turbo Expo 2016, Seoul, South Korea, 2016, Paper No: GT2016-56847.

[57] Kang J., Vorobiev A., Cameron J.D., et al., 10 MW-class sCO2 compressor test facility at university of notre dame. The 4th European sCO2 Conference for Energy, Online Conference, 2021.

[58] Zhang L., Klemeš J.J., Zeng M., et al., Dynamic study of the extraction ratio and interstage pressure ratio distribution in typical layouts of SCO2 Brayton cycle under temperature fluctuations. Applied Thermal Engineering, 2022, 212: 118553.

[59] Cao R., Li Z., Deng Q., et al., Effect of the hub cavity leakage on the aerodynamic performance and strength characteristics of the 150 kW SCO2 centrifugal compressor. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2022, 236(8): 1472–1488.

[60] Ha M., Holder J., Ghimire S., et al., Detailed design and optimization of the first stage of an axial supercritical CO2 compressor. Turbomachinery Technical Conference and Exposition. Rotterdam, The Netherlands, 2022, Paper No: GT2022-82590.

[61] Xiang H., Chen J., Aerothermodynamics optimal design of a multistage axial compressor in a gas turbine using directly manipulated free-form deformation. Case Studies in Thermal Engineering, 2021, 26: 101142.

[62] Boyce M.P., Axial-flow compressors. Gas Turbine Engineering Handbook, 2012, pp. 303–355.