[1] Gu J.R., Liu Q.W., Zhong W.Q., et al., Study on scale-up characteristics of oxy-fuel combustion in circulating fluidized bed boiler by 3D CFD simulation. Advanced Powder Technology, 2020, 31: 2136–2151.

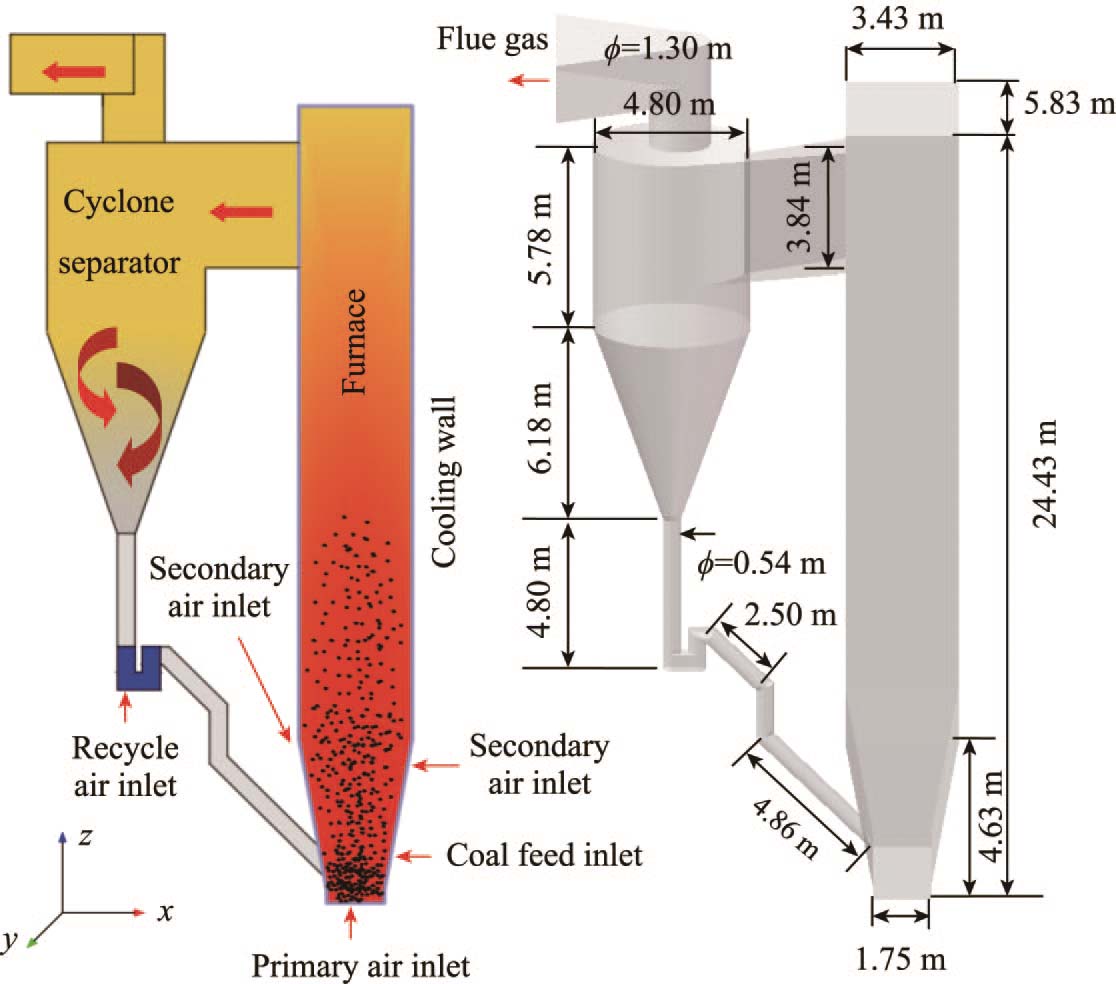

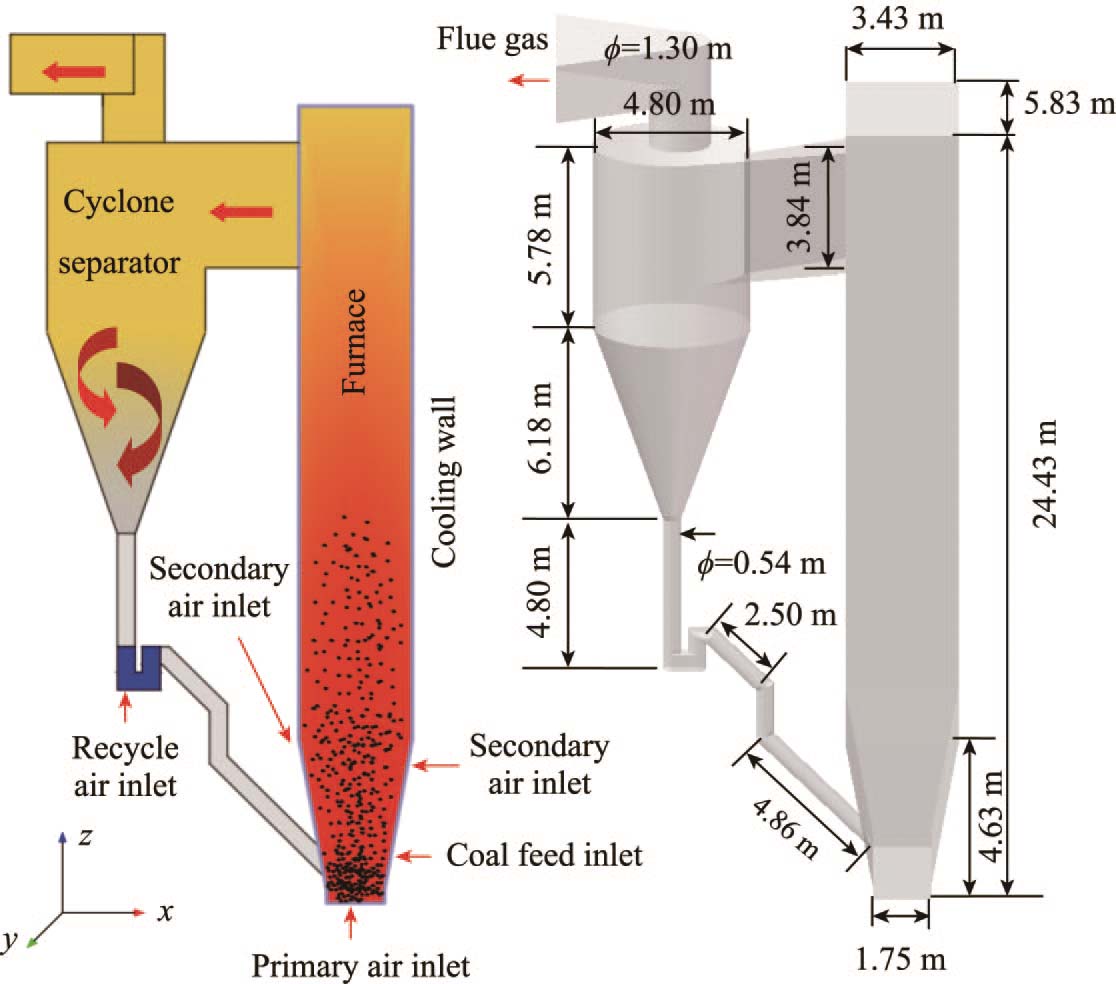

[2] Zhang N., Lu B., Wang W., et al., 3D CFD simulation of hydrodynamics of a 150 MWe circulating fluidized bed boiler. Chemical Engineering Journal, 2010, 162: 821–828.

[3] Li J., Fan B.G., Zheng X.R., et al., Mercury emission and adsorption characteristics of fly ash in PC and CFB boilers. Frontiers in Energy, 2021, 15: 112–123.

[4] Barišić V., Peltola K., Zabetta E.C., Role of pulverized coal ash against agglomeration, fouling, and corrosion in circulating fluidized-bed boilers firing challenging biomass. Energy and Fuels, 2013, 27: 5706–5713.

[5] Wei F., Yang G.Q., Jin Y., et al., The characteristics of cluster in a high density circulating fluidized bed. Canadian Journal of Chemical Engineering, 2010, 73: 650–655.

[6] Zheng W., Zhang M., Zhang Y., et al., The effect of the secondary air injection on the gas-solid flow characteristics in the circulating fluidized bed. Chemistry Engineering Research and Design, 2019, 141: 220–228.

[7] Tu Q., Wang H., Effects of riser geometry on gas-solid flow characteristics in circulating fluidized beds. Particuology, 2020, 49: 205–217.

[8] Mu L., Chen J.B., Yin H., et al., Pyrolysis behaviors and kinetics of refining and chemicals wastewater, lignite and their blends through TGA. Bioresource Technology, 2015, 180: 22–31.

[9] Mu L., Chen J.B., Yao P., et al., Evaluation of co-pyrolysis petrochemical wastewater sludge with lignite in a thermogravimetric analyzer and a packed-bed reactor: Pyrolysis characteristics, kinetics, and products analysis. Bioresource Technology, 2016, 221: 147–156.

[10] Song G., Yang Z., Lyu Q., Investigation of gas-solid flow and temperature distribution uniformity of 350 MW supercritical CFB boiler with polygonal furnace. Powder Technology, 2019, 355: 213–225.

[11] Luo K., Wu F., Yang S., et al., High-fidelity simulation of the 3-D full-loop gas-solid flow characteristics in the circulating fluidized bed. Chemical Engineering Science, 2015, 123: 22–38.

[12] Wang X., Wu X., Lei F., et al., 3D full-loop simulation and experimental verification of gas-solid flow hydrodynamics in a dense circulating fluidized bed. Particuology, 2014, 16: 218–226.

[13] Sun Z., Zhu J., Zhang C., Numerical study on the hydrodynamics in high-density gas-solid circulating fluidized bed downer reactors. Powder Technology, 2020, 370: 184–196.

[14] Xie J., Zhong W., Shao Y., et al., Simulation of co-gasification of coal and wood in a dual fluidized bed system. Advanced Powder Technology, 2021, 32: 52–71.

[15] Loha C., Chattopadhyay H., Pradip K., Chatterjee. Assessment of drag models in simulating bubbling fluidized bed hydrodynamics. Chemical Engineering Science, 2012, 75: 400–407.

[16] Wang X., Jin B., Zhong W., Three-dimensional simulation of fluidized bed coal gasification. Chemical Engineering Process, 2009, 48: 695–705.

[17] Ocampo A., Arenas E., Chejne F., et al., An experimental study on gasification of Colombian coal in fluidised bed. Fuel, 2003, 82: 161–164.

[18] Oevermann M., Gerber S., Behrendt F., Euler-Lagrange/ DEM simulation of wood gasification in a bubbling fluidized bed reactor. Particuology, 2007, 7: 307–316.

[19] Snider D., An incompressible three-dimensional multiphase particle-in-cell model for dense particle flows. Journal of Computational Physics, 2001, 170: 523–549.

[20] Wang Q., Yang H., Wang P., et al., Application of CPFD method in the simulation of a circulating fluidized bed with a loop seal Part II—Investigation of solids circulation. Powder Technology, 2014, 253: 822–828.

[21] Venkatesan V., Mukundarajan L., Narayanan A., Simulation of a scaled down 250 MWe CFB boiler using computational particle fluid dynamics numerical model. Chemical Product and Process Modeling, 2019, 15: 1–26.

[22] Gao M., Zhang B., Hong F., et al., Design and application of the feed water control strategy for a 350 MW circulating fluidized bed boiler. Applied Thermal Engineering, 2017, 125: 1–8.

[23] Yan J., Lu X., Song Y., et al., A comprehensive understanding of the non-uniform characteristics and regulation mechanism of six external loops in a 600 MW supercritical CFB boiler. Energy, 2021, 222: 120032.

[24] Yang W., Handbook of fluidization and fluid-particle systems. China Part 1, 2003, 137: 1–8.

[25] Fan L., Zhu C., Principles of gas-solid flows. Cambridge University Press (CUP), 1988.

[26] Andrews M., O'Rourke P., The multiphase particle-in-cell (MP-PIC) method for dense particulate flows. International Journal of Multiphase Flow, 1996, 22: 379–402.

[27] Gu J., Zhong W., Shao Y., et al., Particle motion behaviors in dual circulation fluidized bed by Multiphase Particle-in-Cell (MP-PIC) Method. Industrial & Engineering Chemistry Research, 2018, 57: 14809–14821.

[28] Abdallah B., Huang A., Shivkumar B., et al., Numerical simulation of a commercial FCC regenerator using Multiphase Particle-in-Cell methodology (MP-PIC). Advanced Powder Technology, 2017, 28: 2947–2960.

[29] Delebarre A., Revisiting the Wen and Yu equations for minimum fluidization velocity prediction. Chemistry Engineering Research and Design, 2004, 82: 587–590.

[30] Gidaspow D., Multiphase flow and fluidization: continuum and kinetic theory description. Journal of Non-Newtonian Fluid Mechanics, 1994, 55: 207–208.

[31] Harris S., Crighton D., Solitons, solitary waves, and voidage disturbances in gas-fluidized beds. Journal of Fluid Mechanics, 1994, 266: 243–276.

[32] Zhong W., Xie J., Shao Y., et al., Three-dimensional modeling of olive cake combustion in CFB. Applied Thermal Engineering, 2015, 88: 322–333.

[33] Zheng M., Shen L., Feng X., et al., Kinetic model for parallel reactions of CaSO4 with CO in chemical-looping combustion. Industrial & Engineering Chemistry Research, 2011, 50: 5414–5427.

[34] Ostrycharczyk M., Krochmalny K., Czerep M., et al., Examinations of the sulfur emission from pulverized lignite fuel, under pyrolysis and oxy-fuel combustion condition. Fuel, 2019, 241: 579–584.

[35] Huang W., Li J., Yang H., DeNOx technology selection and optimal design of SNCR system for a 300 MWe CFB boiler. Advanced Functional Materials, 2014, 492: 7–12.

[36] Zhao J., Brereton C., Grace J., et al., Gas concentration profiles and NOx formation in circulating fluidized bed combustion. Fuel, 1997, 76: 853–860.