[1]

Battisti F.G., de Araujo Passos L.A., da Silva A.K., Performance mapping of packed-bed thermal energy storage systems for concentrating solar-powered plants using supercritical carbon dioxide. Applied Thermal Engineering, 2021, 183: 116032.

[2]

Battisti F.G., de Araujo Passos L.A., da Silva A.K., Economic and environmental assessment of a CO2 solar-powered plant with packed-bed thermal energy storage. Applied Energy, 2022, 314: 118913.

[3]

Anandan S.S., Sundarababu J., A comprehensive review on mobilized thermal energy storage. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2021, pp. 1–24. DOI: 10.1080/15567036.2021.1942331

[4]

Achkari O., El Fadar A., Latest developments on TES and CSP technologies-Energy and environmental issues, applications and research trends. Applied Thermal Engineering, 2020, 167: 114806.

[5]

Esence T., Bruch A., Molina S., et al., A review on experience feedback and numerical modeling of packed-bed thermal energy storage systems. Solar Energy, 2017, 153: 628–654.

[6]

Touzo A., Olives R., Dejean G., et al., Experimental and numerical analysis of a packed bed thermal energy storage system designed to recover high temperature waste heat: an industrial scale up. Journal of Energy Storage, 2020, 32: 101894.

[7]

Zhou H., Shi H., Lai Z., et al., Migration and phase change study of leaking molten salt in tank foundation material. Applied Thermal Engineering, 2020, 170: 114968.

[8]

Gautam A., Saini R.P., A review on sensible heat based packed bed solar thermal energy storage system for low temperature applications. Solar Energy, 2020, 207: 937–956.

[9]

Amiri L., Ermagan H., Kurnia J.C., et al., Progress on rock thermal energy storage (RTES): A state of the art review. Energy Science & Engineering, 2024, 12(2): 410–437.

[10]

Gerstle W.H., Schroeder N.R., McLaughlin L.P., et al., Experimental testing and computational modeling of a radial packed bed for thermal energy storage. Solar Energy, 2023, 264: 111993.

[11]

Knobloch K., Muhammad Y., Costa M.S., et al., A partially underground rock bed thermal energy storage with a novel air flow configuration. Applied Energy, 2022, 315: 118931.

[12]

Soprani S., Marongiu F., Christensen L., et al., Design and testing of a horizontal rock bed for high temperature thermal energy storage. Applied Energy, 2019, 251: 113345.

[13]

Nicolas L.F., Falcoz Q., Pham Minh D., et al., Flexibility and robustness of a high-temperature air/ceramic thermocline heat storage pilot. Journal of Energy Storage, 2019, 21: 393–404.

[14]

Yang B., Bai F., Wang Y., et al., Study on standby process of an air-based solid packed bed for flexible high-temperature heat storage: Experimental results and modelling. Applied Energy, 2019, 238: 135–146.

[15]

Cascetta M., Serra F., Cau G., et al., Comparison between experimental and numerical results of a packed-bed thermal energy storage system in continuous operation. Energy Procedia, 2018, 148: 234–241.

[16]

Trevisan S., Guedez R., Design optimization of an innovative layered radial-flow high-temperature packed bed thermal energy storage. Journal of Energy Storage, 2024, 83: 110767.

[17]

Trevisan S., Wang W., Guedez R., et al., Experimental evaluation of an innovative radial-flow high-temperature packed bed thermal energy storage. Applied Energy, 2022, 311: 118672.

[18]

Wang Y., Wang Z., Yuan G., Control strategy effect on storage performance for packed-bed thermal energy storage. Solar Energy, 2023, 253: 78–84.

[19]

Agrawal P., Gautam A., Kunwar A., et al., Performance assessment of heat transfer and friction characteristics of a packed bed heat storage system embedded with internal grooved cylinders. Solar Energy, 2018, 161: 148–158.

[20]

Gautam A., Saini R.P., Experimental investigation of heat transfer and fluid flow behavior of packed bed solar thermal energy storage system having spheres as packing element with pores. Solar Energy, 2020, 204: 530–541.

[21]

Ameen M.T., Ma Z., Smallbone A., et al., Experimental study and analysis of a novel layered packed-bed for thermal energy storage applications: A proof of concept. Energy Conversion and Management, 2023, 277: 116648.

[22]

Kocak B., Fernandez A.I., Paksoy H., Benchmarking study of demolition wastes with different waste materials as sensible thermal energy storage. Solar Energy Materials and Solar Cells, 2021, 219: 110777.

[23]

Kocak B., Paksoy H., Performance of laboratory scale packed-bed thermal energy storage using new demolition waste based sensible heat materials for industrial solar applications. Solar Energy, 2020, 211: 1335–1346.

[24]

Lai Z., Cen K., Zhou H., Applicability of coal slag for application as packed bed thermal energy storage materials. Solar Energy, 2022, 236: 733–742.

[25]

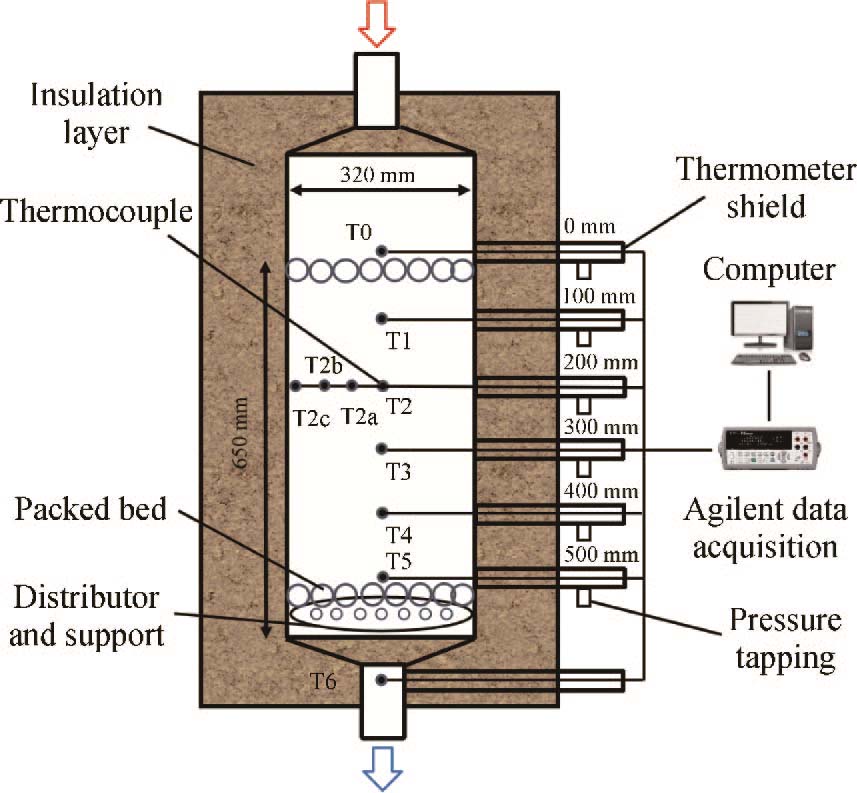

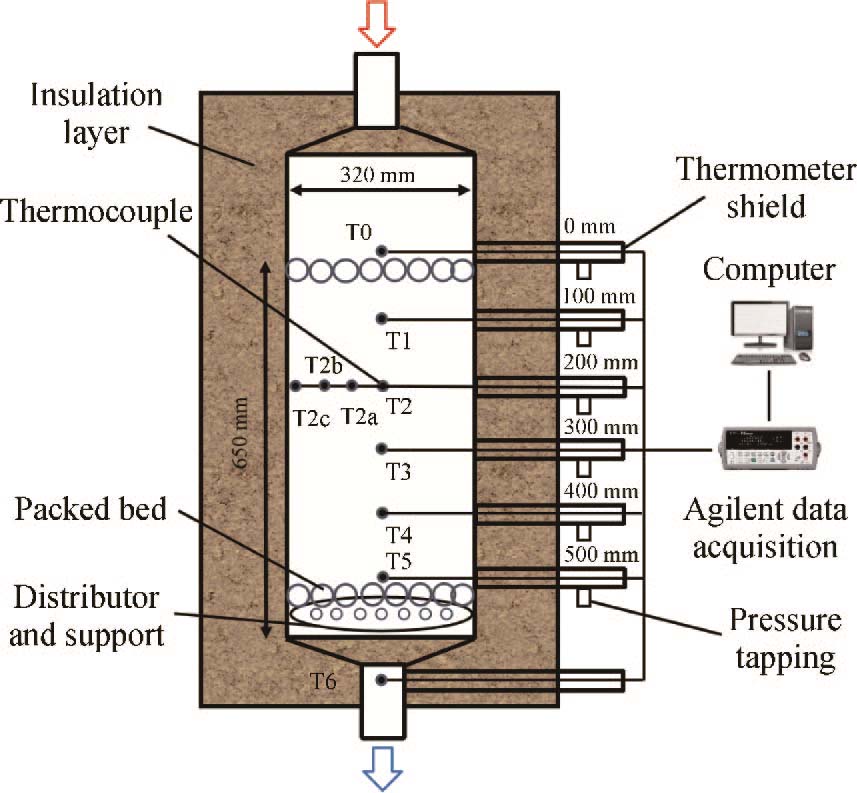

Rong Y., Huang S., Zhou H., Experimental study on storage performance of packed bed solar thermal energy storage system using steel slag. Journal of Energy Storage, 2024, 78: 110042.

[26]

Lai Z., Zhou H., Zhou M., et al., Experimental study on storage performance of packed bed thermal energy storage system using sintered ore particles. Solar Energy Materials and Solar Cells, 2022, 238: 111654.

[27]

Foumeny E.A., Moallemi H.A., Mcgreavy C., et al., Elucidation of mean voidage in packed beds. The Canadian Journal of Chemical Engineering, 1991, 69: 1010–1015.

[28]

Freund H., Zeiser T., Huber F., et al., Numerical simulations of single phase reacting flows in randomly packed fixed-bed reactors and experimental validation. Chemical Engineering Science, 2003, 58: 903–910.

[29]

Zhou H., Lai Z., Cen K., Experimental study on energy storage performances of packed bed with different solid materials. Energy, 2022, 246: 123416.

[30]

ELSihy E.S., Xu C., Du X., Numerical study on the dynamic performance of combined sensible-latent heat packed-bed thermocline tank. Journal of Energy Resources Technology, 2022, 144: 012001.

[31]

Avila-Marin A.L., Alvarez-Lara M., Fernandez-Reche J., A regenerative heat storage system for central receiver technology working with atmospheric air. Solar PACES 2013, Energy Procedia. 2014, 49: 705–714.

[32]

Hänchen M., Brückner S., Steinfeld A., High-temperature thermal storage using a packed bed of rocks—heat transfer analysis and experimental validation. Applied Thermal Engineering, 2011, 31: 1798–1806.

[33]

Zhou H., Wang Z., Zhou M., et al., Thermal properties, permeability and compressive strength of highly porous accumulated ceramsites in the foundation of salt tank for concentrate solar power plants. Applied Thermal Engineering, 2020, 164: 114451.

[34]

Costantini M., Colosi C., Jaroszewicz J., et al., Microfluidic foaming: a powerful tool for tailoring the morphological and permeability properties of sponge-like biopolymeric scaffolds. ACS Applied Materials & Interfaces, 2015, 7(42): 23660–23671.

[35]

Robert J.M., Describing the uncertainties in experimental results. Experimental Thermal and Fluid Science, 1988, 1: 3–17.

[36]

Zanganeh G., Pedretti A., Zavattoni S., et al., Packed-bed thermal storage for concentrated solar power-Pilot-scale demonstration and industrial-scale design. Solar Energy, 2012, 86: 3084–3098.