[1] Howell R.J., Hodson H.P., Schulte V., et al., Boundary layer development in the BR710 and BR715 LP turbines-the implementation of high-lift and ultra-high-lift concepts. Journal of Turbomachinery, 2002, 124(3): 385–392.

[2] Wu F., Jiang W., Yue Y., et al., Experimental and numerical investigation on aerodynamic performance of biomimetic blade in steam turbine. International Journal of Thermal Sciences, 2023, 192: 108447.

[3] Coull J.D., Endwall loss in turbine cascades. Journal of Turbomachinery, 2017, 139(8): 081004.

[4] Moustapha S.H., Okapuu U., Williamson R.G., Influence of rotor blade aerodynamic loading on the performance of a highly loaded turbine stage. Journal of Turbomachinery, 1987, 109(2): 155–161.

[5] Hawthorne W.R., Rotational flow through cascades Part I. The components of vorticity. The Quarterly Journal of Mechanics and Applied Mathematics, 1955, 8(3): 266–279.

[6] Hawthorne W.R., Armstrong W.D., Rotational flow through cascades Part II. The circulation about the cascade. The Quarterly Journal of Mechanics and Applied Mathematics, 1955, 8(3): 280–292.

[7] Wang H.P., Olson S.J., Goldstein R.J., et al., Flow visualization in a linear turbine cascade of high performance turbine blades. Journal of Turbomachinery, 1997, 119(1): 1–8.

[8] Filippov G.A., Wang Z.Q., The calculation of axial symmetric flow in a turbine stage with small ratio of diameter to blade length. Journal of Moscow Power Institute, 1963, 47: 63–78.

[9] Harrison S., The influence of blade lean on turbine losses. Journal of Turbomachinery, 1992, 114(1): 184–190.

[10] Tan C.Q., Yamamoto A., Mizuki S., et al., Influences of blade bowing on flowfields of turbine stator cascades. AIAA Journal, 2012, 41(10): 1967–1972.

[11] Tan C.Q., Yamamoto A., Chen H.S., et al., Flowfield and aerodynamic performance of a turbine stator cascade with bowed blades. AIAA Journal, 2004, 42(10): 2170–2171.

[12] Xie J., Xia C., Zhang Y., et al., Micro axial turbine bowed blade design at low aspect radio. Journal of Nanjing University of Aeronautics & Astronautics, 2015, 47(1): 160.

[13] Moustapha S.H., Paron G.J., Wade J.H.T., Secondary flows in cascades of highly loaded turbine blades. Journal of Engineering for Gas Turbines and Power, 1985, 107(4): 1031–1038.

[14] Tan C.Q., Zhang H.L., Xia H.D., et al., Blade bowing effect on aerodynamic performance of a highly loaded turbine cascade. Journal of Propulsion and Power, 2010, 26(3): 604–608.

[15] Chen S.W., Li W.H., Effects of combined sweeping jet actuator and winglet tip on aerodynamic performance in a turbine cascade. Aerospace Science and Technology, 2022, 131: 107956.

[16] Kopper F.C., Milanot R., Vancot M., Experimental investigation of endwall profiling in a turbine vane cascade. AIAA Journal, 1981, 19(8): 1033–1040.

[17] Hartland J.C., Gregory-Smith D.G., Harvey N.W., et al., Non-axisymmetrical turbine end wall design: part II—experimental validation. Journal of Turbomachinery, 2000, 122(2): 286–293.

[18] Harvey N.W., Rose M.G., Taylor M.D., et al., Non-axisymmetrical turbine end wall design: Part I - three-dimensional linear design system. Journal of Turbomachinery, 2000, 122(2): 278–285.

[19] Su X., Bian X., Li H., et al., Unsteady flows of a highly loaded turbine blade with flat endwall and contoured endwall. Aerospace Science and Technology, 2021, 118: 106989.

[20] Turgut Ö.H., Camci C., A simultaneous use of a leading-edge fillet and a non-axisymmetrically contoured endwall in a turbine stage. Aerospace Science and Technology, 2021, 118: 106985.

[21] Nagel M.G., Baier R.D., Experimentally verified numerical optimization of a three-dimensional parametrized turbine vane with non-axisymmetrical end walls. Journal of Turbomachinery, 2005, 127(2): 380–387.

[22] Saha A.K., Acharya S., Computations of turbulent flow and heat transfer through a three-dimensional non-axisymmetrical blade passage. Journal of Turbomachinery, 2008, 130(3): 031008.

[23] Zhang K.Y., Li Z.G., Li J., Non-axisymmetric endwall contour optimization and performance assessment as affected by simulated swirl purge flow and backward hole injection. International Journal of Thermal Sciences, 2022, 172: 107297.

[24] Tao Z., Yu B.Y., Li Y.X., et al., Effects of non-axisymmetric endwall contouring on aerothermal performance of a gas turbine blade endwall with a purge flow. International Journal of Thermal Sciences, 2021, 164: 106921.

[25] Langston L.S., Secondary flows in axial turbines—A review. Annals of the New York Academy of Sciences, 2001, 934(1): 11–26.

[26] Zhou X., Xue X., Du X., et al., Aerodynamic comparison between increasing cascade pitch and turning angle in the highly-loaded design. Journal of Thermal Science, 2022, 31(05): 1709–1722.

[27] Xue X., Zhou X., Liu X., et al., Investigation on pitch-wise non-uniform and inflecting inlet flow of low-speed plane cascade. ASME Turbo Expo: Turbomachinery Technical Conference & Exposition, 2016, Article No: GT2016-56934.

[28] Menter F.R., Two equation eddy viscosity model for engineering applications. AIAA Journal, 1994, 32(8): 1598–1605.

[29] Langtry R.B., Menter F.R., Likki S.R., et al., A correlation-based transition model using local variables-part I: Model formulation. Journal of Turbomachinery, 2006, 128(3): 413–422.

[30] Kim J.J., Sohn H.S., Song H.S., et al., Effect of profiled endwall on heat transfer under different turbulence intensitie. International Communications in Heat and Mass Transfer, 2022, 133: 105935.

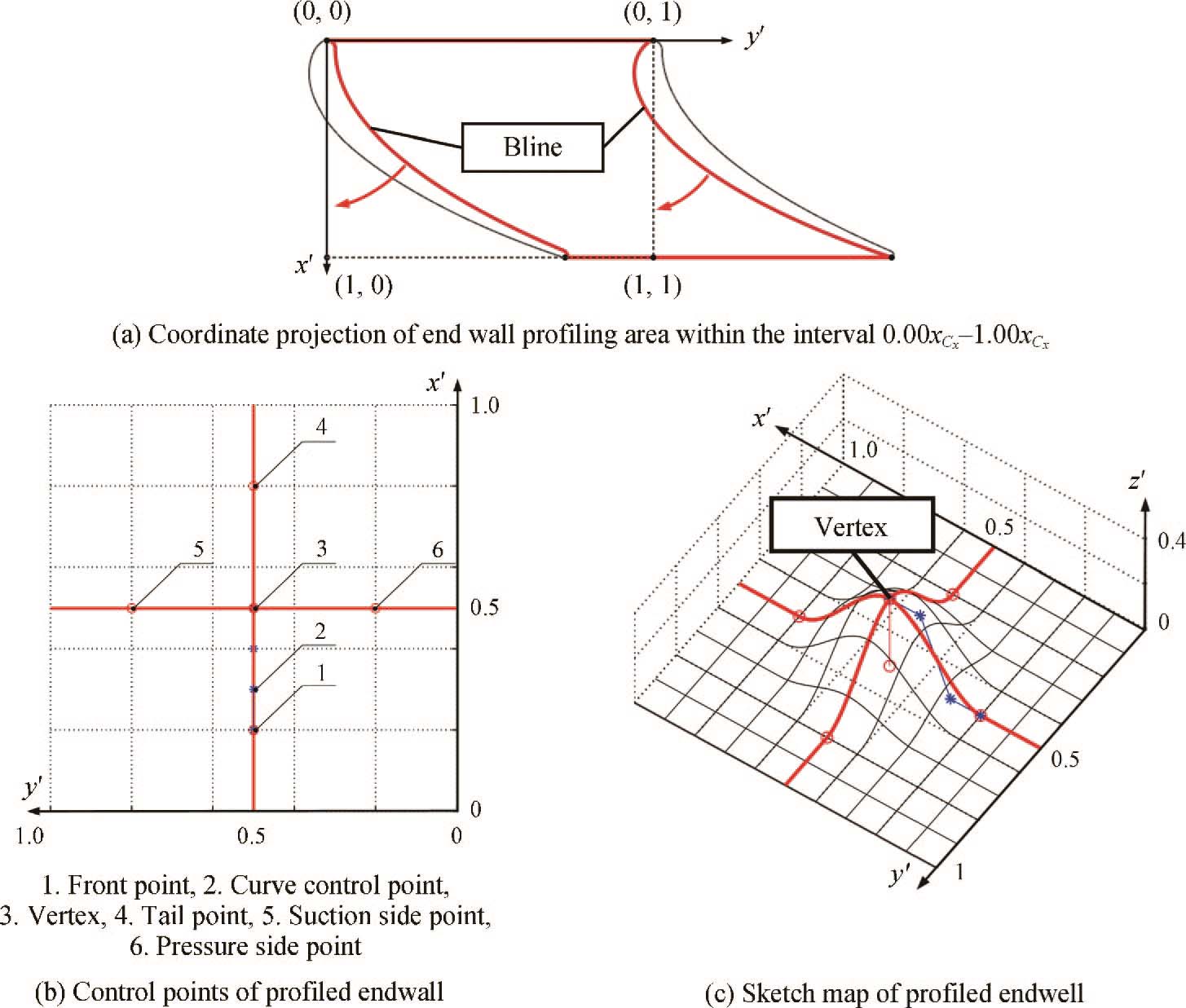

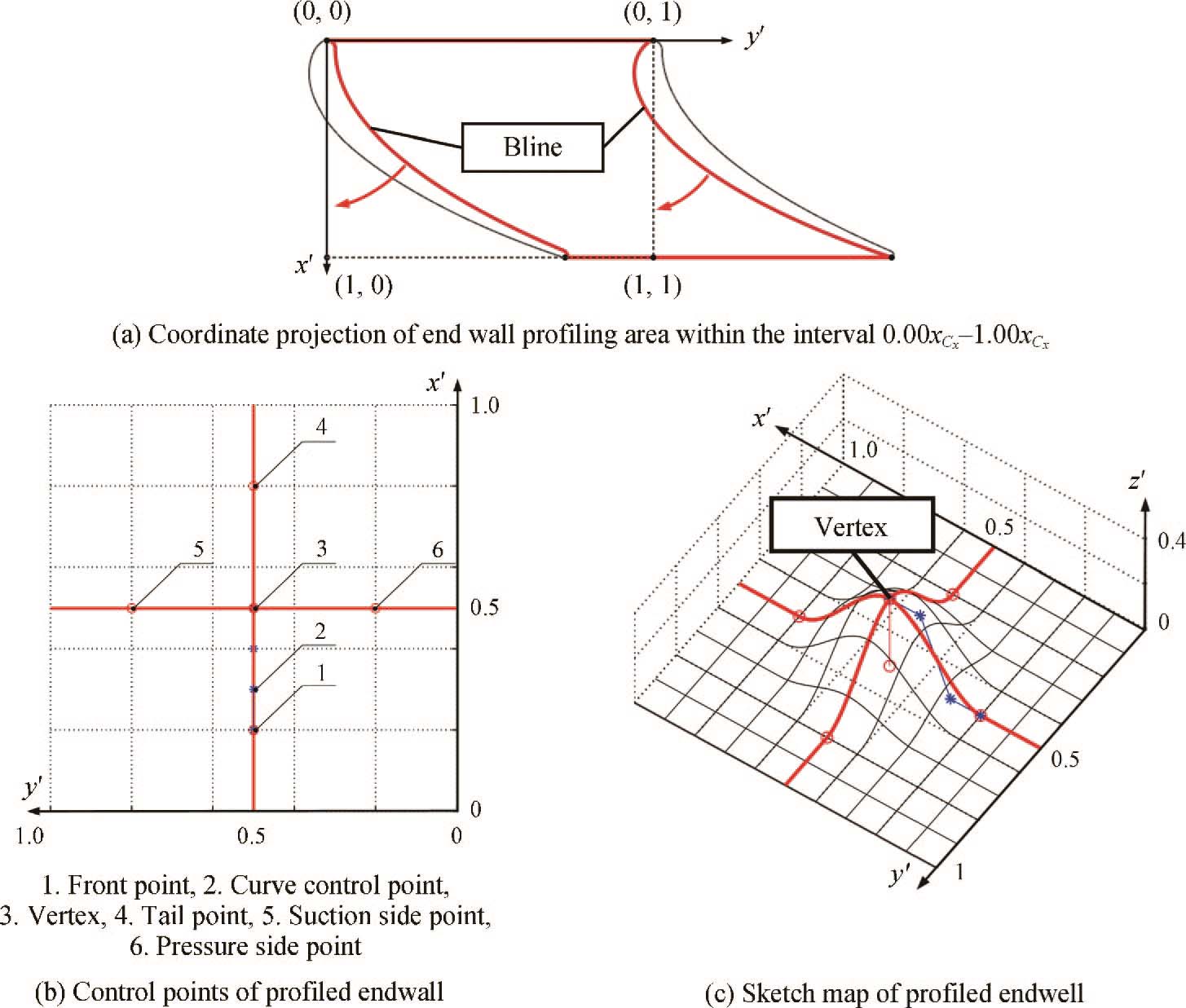

[31] Hartland J., Gregorysmith D., A design method for the profiling of end walls in turbines. ASME Turbo Expo 2002: Power for Land, Sea, and Air, 2002, Article No: GT2002-30433.

[32] Liu W., Wang S.T., Wen F.B., Numerical investigation of a turbine stator with non-axisymmetric endwall profiling. International Journal of Thermal Sciences, 2022, 31(5): 1790–1803.

[33] Tang H., Liu S., Luo H., Design optimization of profiled endwall in a high work turbine. ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, 2014, Article No: GT2014-26190.